42

Maintenance

© Travis Industries

4012412

100-01270_000

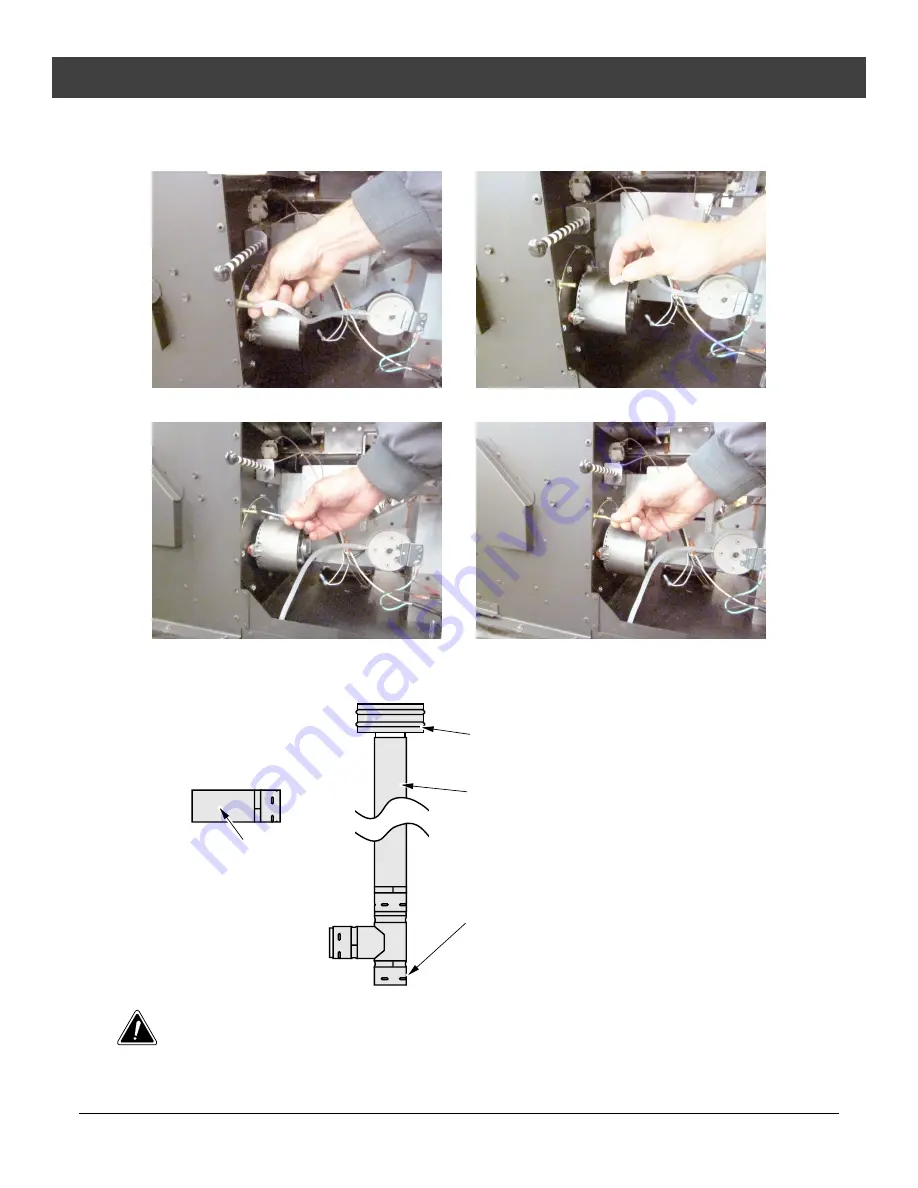

Yearly Maintenance (or Every Ton of Pellets) - Clean the Negative Pressure Tube

1. Disconnect the end of the tube from the combustion blower.

2. Clean the nozzle using a pipe cleaner.

Yearly Maintenance (or Every Ton of Pellets) - Clean the Vent

WHENEVER ANY PORTION OF THE PELLET VENT IS DISCONNECTED, THE JOINTS MUST

BE SEALED WITH RTV 500° F. SILICONE SEALANT, UNLESS OTHERWISE SPECIFIED BY

THE VENT MANUFACTURER.

Check the vent sections for creosote

accumulation (indicating a poorly burning

stove). Accumulation over 1/4” must be

removed.

On vertically vented systems, the dirtiest portion

is often the point where the vent turns upwards

(i.e. the "Tee"). Fortunately, the "Tee" has a built-

in clean-out cover. Place a container under the

“Tee”, disconnect the cover and remove all flyash.

While open, use a flashlight to look up the vent to

check for build-up.

Make sure the cap is free of debris

(especially if it has a screen that could

become blocked).

Flyash will deposit along

sections that are horizontal.