Fireplace

Insert

Installation

(for qualified installers only)

17

© Travis Industries

93508061

4050526

SAFETY NOTICE:

Please read this entire manual before you install and use your new room heater. Failure to

follow instructions may result in property damage, bodily injury, or even death. Contact

local building or fire officials about restrictions and installation inspection requirements in

your area.

Planning The Installation

We suggest that you have an authorized Travis Industries dealer install your fireplace insert. If you

install the fireplace insert yourself, your authorized dealer should review your installation plans.

Check with local building officials for any permits required for installation of this fireplace insert and

notify your insurance company before proceeding with installation.

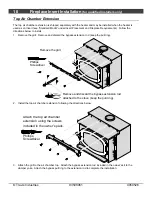

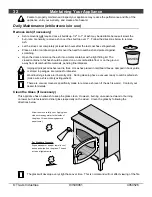

Preparation for Installation

x

Check for damage to the exterior of the fireplace insert (dents should be reported, scratches can be

fixed by applying touch up paint).

x

Check the interior of the firebox (replace cracked firebrick and make sure baffle is in place).

The fireplace insert can be lightened by removing the firebricks and baffle (pg 36) - replace before

operation.

Additional Accessories Needed for Installation

x

Surround Panels (see page 44)

Standard vs. Cook-Top Installations

The top air chamber extension is shipped separately with the heater (see the following page for details).

When installed, the unit is considered a “Standard Model” for Insert Placement and Fireplace Requirements.

If it is not installed, the unit is considered a “Cook-Top Model” for Insert Placement and Fireplace

Requirements.

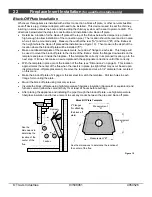

Installation Considerations

Installation Type

Considerations

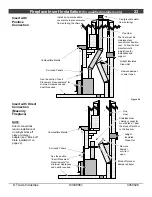

Insert with Positive Flue (Full Reline)

(Page

23)

• Utilizes existing masonry fireplace

• Provides best draft

• Easiest to clean

Insert with Direct Connect Flue

(Page

23)

• Utilizes existing masonry fireplace

• Provides good draft

• Requires fireplace block-off plate - see page 22

Insert with Face Seal Connection

(Page

24)

NOTE

: Before installing verify with local building

officials that this type of installation is

approved in your area.

• Utilizes existing masonry fireplaces with cross section

of 28" to 144"

• Provides marginal draft

• Easiest to install

• Requires the optional surround panels and insulation

(see "Surround Panels" on page 44).