Installation

(for qualified installers only)

17

© Travis Industries

4121120

100-01315

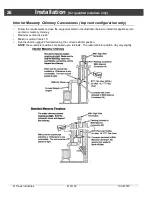

Exhaust Restrictor

NOTE: Refer to the vent configuration (pages 18 to 23) to determine the correct restrictor position.

Exhaust Restrictor Extender Plate

NOTE: Refer to the vent configuration (pages 18 to 23) to determine if the extender must be installed.

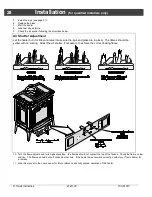

Diffuser

NOTE: Refer to the vent configuration (pages 18 to 23) to determine if the diffuser must be adjusted.

•

The diffuser is best accessed while converting the appliance to rear vent (see page 10).