10

before continuing.

CAUTION: Whenever the machine overloads, always run the machine at no load for a few minutes to

allow the temperature to return to normal before proceeding to work.

SPEED STABILIZATION

This machine is equipped with an electronic speed stabilization

system which maintains constant speed under load.

VARIABLE SPEED FUNCTION

The motor's speed can be varied to suit the needs of different work

situations. Turn the Variable Speed Thumbwheel clockwise to increase

speed and anti-clockwise to decrease.

VACUUM CONNECTION

WARNING: Dust developing while working can be harmful to one’s health.

This machine is designed specifically for dry grinding of concrete and similar materials. It uses dry diamond cup

wheels and must be used with a suitable vacuum cleaner. Never exhaust the dust directly into the

atmosphere.

To attach vacuum hose to Dust Port,hold machine firmly with one hand. Then with a twisting motion push the

vacuum hose onto the Dust Port.

SAFETY GUARD

The Safety Guard (ie. the Skirt) must be used at all times when operating this machine. It is not adjustable. The

Half-Moon Door may be temporarily removed to expose the Edge Cut-Out. See below.

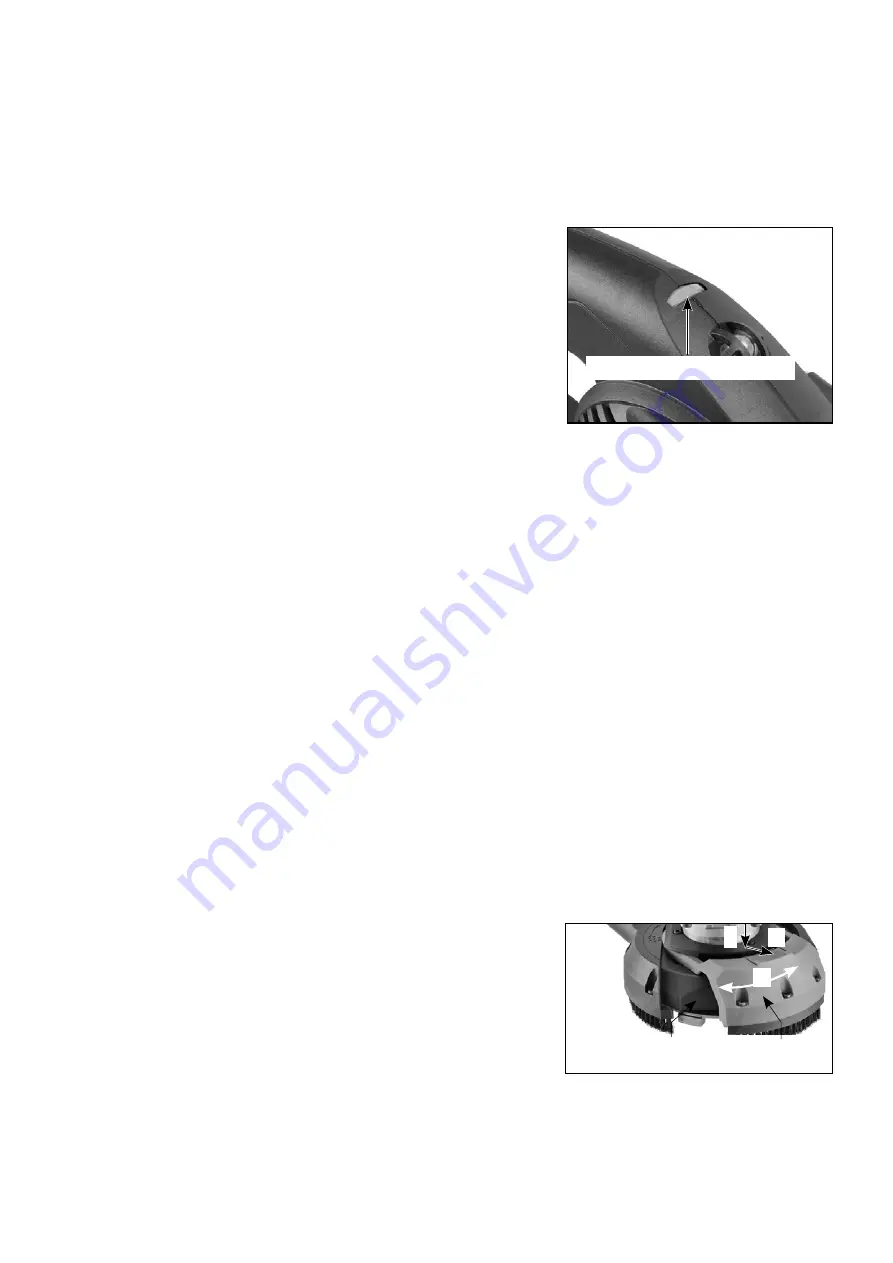

THE EDGE CUT-OUT

When working against a wall or into a corner, the Skirt will prevent

the grinding head from reaching all the way to the edge.

Press the Tab, slide the Half-Moon Door outward to unlock, then

rotate the Half-Moon Door to the side until it clicks.

Keep the mechanism clean. Accumulated dust will make make it

difficult to open.

Variable Speed Thumbwheel

Edge Cut-Out in Skirt

Half-Moon Door

3

2

1