1/16 SUMMIT VXL • 23

TUNING ADJUSTMENTS

wheels. Your model will generally benefit from higher viscosity oil

when climbing, rock crawling, or racing on low-traction surfaces.

From the factory, both the differentials are filled with SAE

30,000W viscosity silicone oil. This fluid gives the 1/16 Summit VXL

versatile multi-terrain handling and allows forgiving cornering

on pavement and other high-grip surfaces. For extreme off-

road terrain, the differentials may be filled with thicker fluid to

increase traction, at the expense of high-speed cornering stability.

100,000W fluid is a good starting point for extreme-terrain use;

500,000W fluid will virtually lock the differentials. The differentials

must be removed from the vehicle and disassembled to change/

replace oil. Only use silicone oil in the differentials. Traxxas sells a

variety of oil viscosities (see your parts list).

Note:

Heavier oil will

allow power to be transferred even with one or more tires off the

ground. This can make the vehicle more likely to overturn.

MOTOR AND GEARING

Extensive testing has been done to determine the best gear ratio

for your model. The stock gearing balances power, speed, and

efficiency to optimize the performance of the model. However,

you may wish to try different gear ratios in order to customize the

performance of your model. The gearing chart on this page shows

appropriate gearing for the model.

By installing a pinion with fewer teeth, or a spur gear with

more teeth, the transmission’s final drive ratio is increased.

This means greater rpm is required to achieve a given speed.

Using a numerically higher gear ratio will increase torque, but

reduce top speed. Installing a pinion with more teeth, or a spur

gear with fewer teeth, will decrease the final drive ratio, which

will generally increase top speed but reduce torque. However,

installing too large a pinion will “overgear” the model, which will

reduce performance and may overheat the motor and speed

control. Use the following formula to calculate the overall ratio for

combinations not listed on the gear chart:

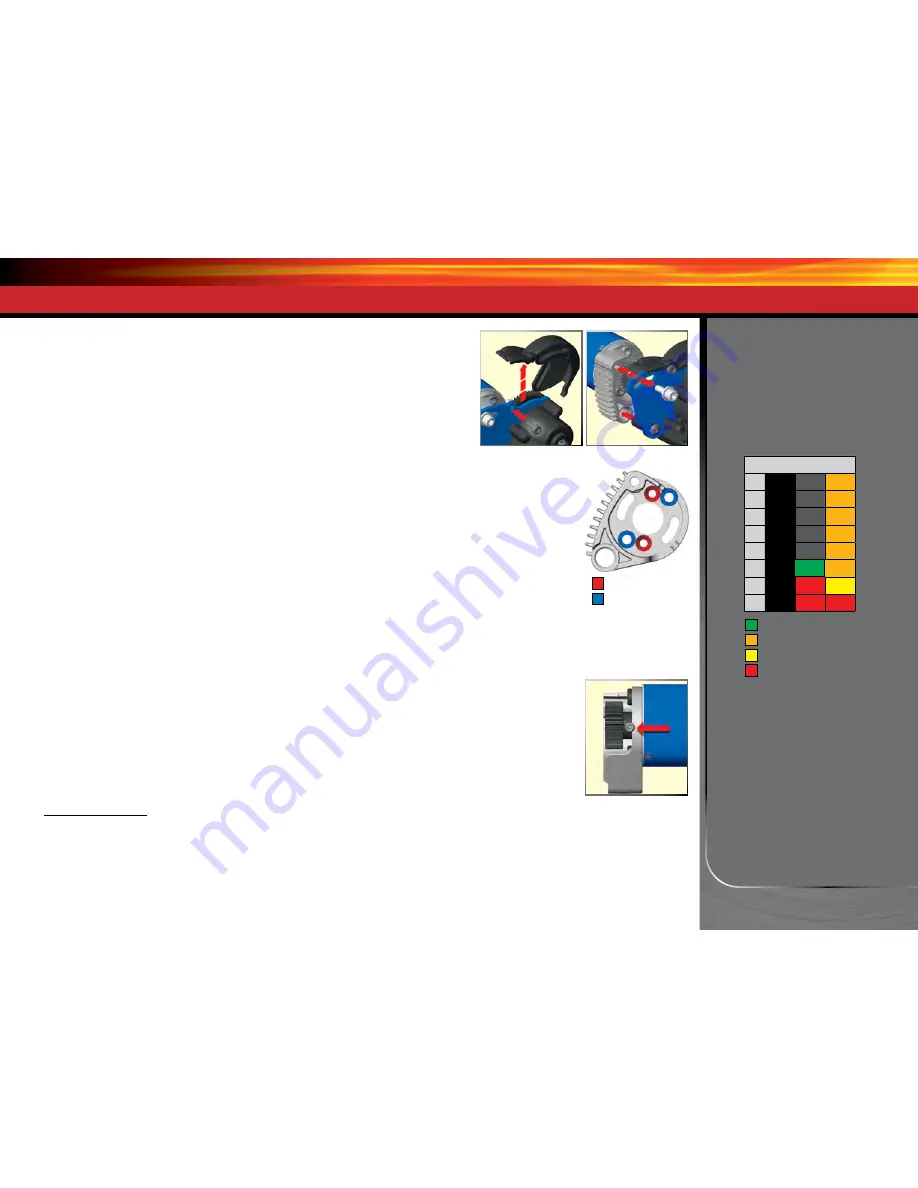

Motor Installation

To access the motor,

remove the gear

cover by removing

the single screw

on the top of the

gear cover. The

motor uses an

aluminum mount

for quick, easy motor access and gearing

adjustment. To remove the motor, first

open the right battery door and slide out

the ESC. Next, remove the single large hex

screw using the supplied 2.5mm wrench.

Then rotate the motor and mount to the

side of the model, and slide backward off

the post.

The motor mount was carefully

engineered to provide additional features

and adjustability. Two sets of holes

are provided for use with brushed and

brushless motors. The holes for brushed motors are spaced 16mm

apart and accept 2.5mm screws. The holes for brushless motors are

spaced 19mm apart and accept 3mm screws.

Pinion Gear Installation Instructions

1. Remove the motor as described

in Motor Installation.

2. Use a1.5mm wrench to loosen the

pinion’s set screw. Remove the pinion.

3. Place the replacement pinion gear onto

the motor shaft. Align the set screw hole

with the flat side of the shaft.

4. Thread a 1.5mm set screw into the

pinion gear but do not tighten it yet.

5. Slide the pinion gear down the motor shaft so the wrench shaft

fits into the notch in the motor mount, as shown. Tighten the

set screw.

# Spur Gear Teeth

x 5.04 = Final Gear Ratio

# Pinion Gear Teeth

Brushed Motors

Brushless Motors

Motor Mount Positions

Gearing Compatibility Chart

This chart shows a full range of gear

combinations. The gear combinations

in gray are not suitable when using the

included 6-cell battery, speed control,

and motor. These gear combinations

have been included in this chart as

they may be used with certain other

aftermarket equipment combinations.

Spur Gear

Pinion Gear

45

50

55

11

-

-

25.20

12

-

-

23.10

13

-

-

21.32

14

-

-

19.80

15

-

-

18.48

16

-

15.75

17.33

17

-

14.82

16.31

18

-

14.00

15.40

Stock setup

Extreme Terrain Gear

Acceptable range

Not suitable for stock model