TRAXXAS RALLY • 21

Fine Tuning the Shocks

The four shocks on the model influence its

handling. Whenever you rebuild your shocks,

or make any changes to the pistons, springs

or oil, always make changes to them in pairs

(front or rear). Piston selection depends on

the range of oil viscosities that you have

available. For example, using a two-hole

piston with a lightweight oil will, at one

point, give you the same damping as a three-

hole piston with heavier oil.

We recommend using the two-hole pistons

with a range of oil viscosities from 10W to

50W (available from your hobby shop). The

thinner viscosity oils (30W or less) flow more

smoothly and are more consistent, while

thicker oils provide more damping. Use only

100% pure silicone shock oil to prolong seal

life. From the factory, shock oil is set to 50W

in the front shocks and 40W in the rear shocks.

The model’s ride height can be adjusted by adding or removing the

clip-on, spring pre-load spacers. Adjust the ride height so that the

suspension arms are slightly above being parallel to the ground.

Observe how your model handles in turns. Proper set-up will add

stability and help prevent spin outs. Experiment with different

springs and shock oils to find what works best for your current track

conditions.

Centering Your Servo

If you have removed the servo horn from your model’s steering servo,

or the servo has been removed for service or cleaning, the servo must

be re-centered prior to installation of the servo horn or installation of

the servo in the model.

1. Remove the servo horn from the steering servo.

2. Connect the steering servo to channel 1 on the receiver. Connect

the electronic speed control (ESC) to channel 2. The white wire on

the servo lead is positioned towards the receiver’s LED.

3. Turn the transmitter power switch on. Make certain the

transmitter’s batteries are no depleted.

4. Turn the transmitter’s steering trim knob to the center “0” position.

5. Disconnect motor wires “A” and “C” (see page 10) to prevent the

motor from turning during the next steps. Connect a fresh battery

pack to the speed control and turn on the ESC (see page 16). The

servo’s output shaft will automatically jump to its center position.

6. Install the servo horn onto the servo output

shaft. Align the servo horn one spline from

center, as shown right.

7. Check servo operation by turning the steering

wheel back and forth to ensure that the

mechanism has been centered properly and

you have equal throw in both directions. Use

the transmitter’s steering trim knob to fine-

tune the position of the servo horn so your

model tracks straight when the steering wheel is at neutral.

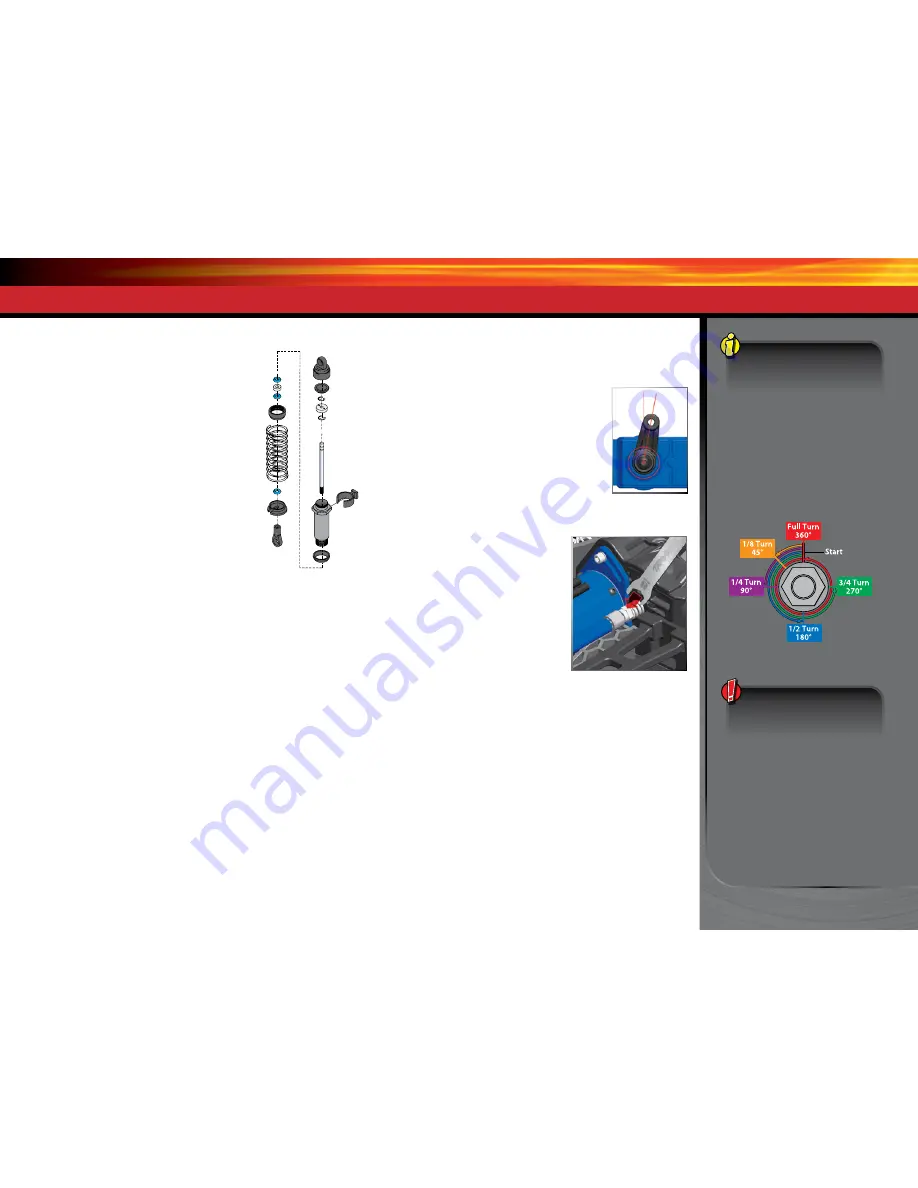

Adjusting the Slipper Clutch

Your model is equipped with an

adjustable slipper clutch which is built

into the large spur gear. The purpose

of the slipper clutch is to regulate the

amount of power sent to the wheels

to prevent tire spin. When it slips, the

slipper clutch makes a high-pitch,

whining noise. To adjust the slipper,

use the included wrench to hold the

adjusting nut and roll the model forward

to tighten and reverse to loosen.

Place the model on a high-traction surface, such as carpet . Adjust the

slipper so that you can hear it slip for approximately two feet from a

standing, full throttle start. (Learn more about adjusting the slipper

clutch in the sidebar.)

BASIC TUNING ADJUSTMENTS

To achieve a good starting

point for the slipper clutch

in this model, remove the

slipper gear assembly from

your model (

see page 22 for

instructions

) and tighten the

slipper clutch adjusting nut

clockwise until the slipper

clutch adjusting spring

fully collapses (do not over

tighten), and then turn the

slipper clutch nut counter-

clockwise one full turn.

Do not run your model with

the slipper clutch adjusting

spring fully compressed. The

minimum recommended

slipper clutch setting is 1/2

turn counter-clockwise from

fully compressed.

If you have questions or need technical assistance, call Traxxas at

1-888-TRAXXAS

(1-888-872-9927) (U.S. residents only)

Pre-load

Spacer