30 • E-REVO VXL BRUSHLESS

This advanced tuning guide will take you one step further into the

cutting edge technology that has been designed into E-Revo. Follow

the instructions provided here to take advantage of E-Revo’s maximum

performance potential.

SUSPENSION AND ALIGNMENT SETTINGS

Caster Adjustment

The caster angle of the front

suspension may be used to adjust

the understeer (push)/oversteer

handling characteristics of the

model. Generally, increasing the

caster angle will move the truck

towards an oversteer condition

(more traction on the front tires, less

on the rear tires). Decreasing the

caster angle will create a tendency

towards understeer (pushing in the

turns). From the factory, the front

suspension is set to a caster angle of

10-degrees. The rear caster angle is

not adjustable. The caster angle

of the front suspension can be

adjusted from 5° to 15°. Adjust

the caster by positioning the

caster adjustment shims on the

upper control arms of the front

suspension as shown in the

table to the right.

Caster Angle, and Bump Steer

Bump steer is unwanted change in the steering angle of the front wheels

as the suspension travels up and down. It can result in unstable and

unpredictable handling. Bump steer is affected by the position of the

outer toe link end on the axle carrier. From the factory, the toe links

are positioned so that bump steer is virtually eliminated (about 3/100

of a degree through the entire range of travel). When the caster angle

is changed, the outer toe link end should be repositioned on the axle

carrier to maintain zero bump steer geometry. Adjustment is achieved

using shims and hollow balls (part #5355 and #5347, sold separately).

Refer to the Bump Steer Elimination chart on page 31, and look up

your caster angle setting to find the correct position for the outer toe

links. Positioning the toe-links correctly will maintain the original factory

geometry and eliminate the unwanted steering angle changes caused by

bump steer.

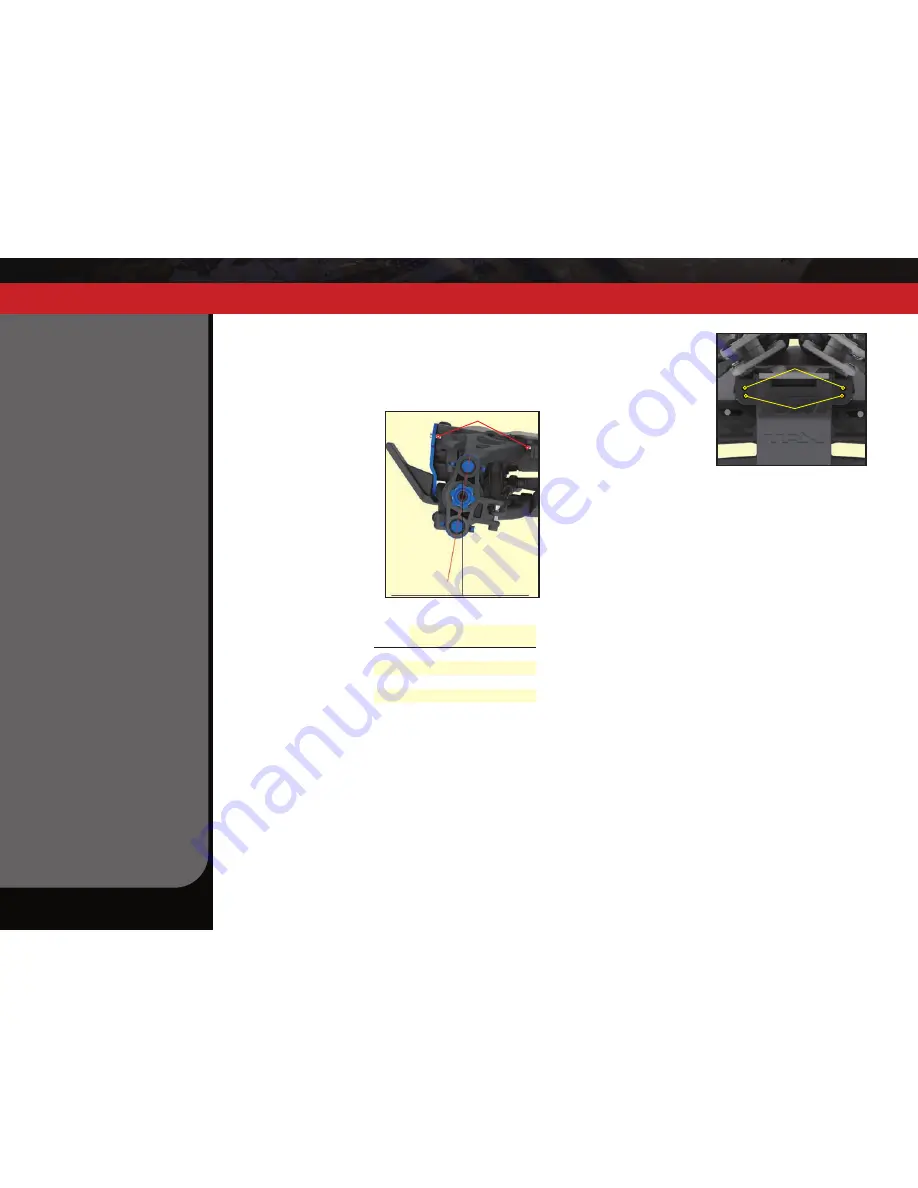

Roll Center

There are two holes on the

bulkheads to mount each upper

suspension arm. The roll center

of the vehicle can be raised by

mounting the upper control arm in

the lower of the two holes. This will

effectively increase the roll stiffness

of the vehicle (similar to installing

swaybars). Adding roll resistance to

one end of the vehicle will tend to

add traction to the opposite end. For example, increasing roll resistance in

the rear by installing the upper arms in the lower holes will provide more

traction for the front wheels and potentially more steering. Installing the

upper arms in the lower holes on the front and rear will increase overall

roll resistance without changing the handling balance. The arms are

installed in the upper position from the factory to make the truck easier

and more forgiving to drive and less likely to traction roll in turns. The

lower holes should be reserved for track tuning.

Note:

When the upper

suspension arms are moved to the lower holes, the front outer toe link

ends and the rear toe control links should be repositioned to eliminate

bump steer. Refer to the Bump Steer Elimination chart on page 31,

and look up your suspension combination (caster angle and roll center

position) to find the correct position for the front outer toe links and the

rear toe control links. Adjustment is achieved using the shims and hollow

balls provided with the vehicle.

Rockers (Progressive Rate/ Suspension Travel)

One of the most exciting aspects of E-Revo’s suspension is the inboard

shock (damper) arrangement that uses pivoting rockers to translate

vertical wheel travel into linear shock motion. The rockers can be changed

to modify the progressive rate of the suspension.

The progressive rate determines how much the force at the wheel

produced by the springs being compressed (wheel force) will vary with

suspension travel (or vertical travel of the wheel). On a progressive

suspension arrangement, the wheel force will increase at a faster and

faster rate as the suspension is compressed. It feels as though the shock

spring gets progressively stiffer the more you compress the suspension.

On a linear suspension arrangement, the wheel force increases linearly as

the suspension is compressed. The spring does not feel any stiffer, even

when the suspension is fully compressed. This provides a very “plush”

feeling suspension with seemingly bottomless suspension travel.

Caster adjustment shims (2 front, 2 rear)

Vertical

Ground plane

10°

Upper Control Arm

Upper Mounting Holes

Upper Control Arm

Lower Mounting Holes

Caster

In Front of

Hinge Pin Boss

Behind Hinge

Pin Boss

5.0°

None

Four

7.5°

One

Three

10.0°

Two

Two

12.5°

Three

One

15.0°

Four

None

Number & Position of Caster Adjustment

Shims (Front Upper Control Arm)

ADVANCED TUNING ADJUSTMENTS