E-Revo • 31

rock crawling, or racing on low traction surfaces.

Note:

Heavier oil

will allow power to be transferred even with one or more tires off the

ground. This can make the vehicle more likely to overturn.

From the factory, both the differentials are filled with SAE 30,000W

viscosity silicone oil. Only use silicone oil in the differentials. Traxxas

sells SAE 10,000W and SAE 50,000W viscosity oil (see your parts list). The

differentials have to be removed from the vehicle and disassembled to

change/replace oil.

Installing the Long Travel Rockers

Use the exploded views included with the model to aid in the installation

process. All of the rockers have labels identifying their proper location;

RF (right front), LF (left front), RR (right rear), and LR (left rear).

Note:

The

exhaust system must be removed to access the rear rocker arms.

1. Remove shock absorbers

Remove the screws that secure the shocks to the chassis shock mounts,

and to the rocker arms.

2. Install long travel shock springs

Replace all four of the 90mm travel shock springs with the four 120mm

long travel shock springs. The front shock springs are indicated by a

silver dot, and the rear shock springs are indicated by a blue dot.

3. Install long travel rockers

Replace the 90mm travel rockers with the long travel rockers by

removing the four 4x6 buttonhead cap screws from the rocker pivot

posts. Remove the 5x11 ball bearings from the rockers. Install the same

5x11 ball bearings in the long travel rockers. Secure the long travel

rockers to the pivots with the same 4x6 buttonhead cap screws.

4. Locate push rods

Make sure that all four of the suspension push rods are located

and secured into the middle position (marked LT) on the lower

suspension arms.

5. Reinstall shock absorbers

Reinstall all four shock absorbers back into their respective locations.

GOING BRUSHLESS

Brushless motors provide increased power output and greater

efficiency. The E-Revo is designed with extra transmission and driveline

strength to make it capable of handling extreme brushless power. One

or two brushless motors may be used. A specially designed motor plate

(part # 5690X) and gear cover (part # 5677X) are available for optimized,

single-motor installations. If you plan to run two brushless motors,

be certain that the front motor is wired for reverse rotation. If you

plan to run LiPo battery packs to power a LiPo-compatible brushless

system, see Using LiPo battery Packs in your E-Revo on page 12 for more

information.

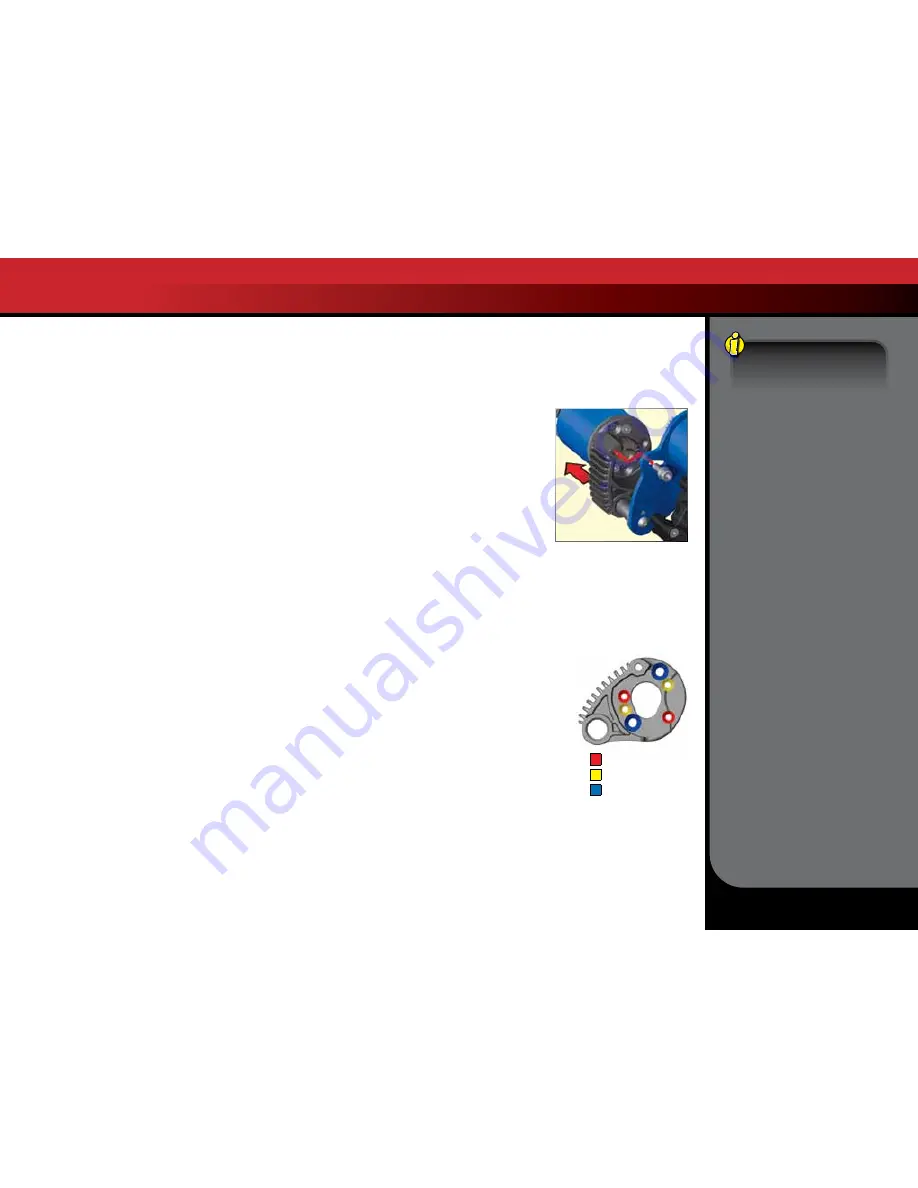

MOTOR INSTALLATION

To access the motors, remove the

gear cover by removing the single

screw on the top of the gear cover.

The front motor is held in place

with two motor screws. Simply

remove the two screws to remove

the motor. The rear motor uses

an aluminum mount for quick,

easy motor access and gearing

adjustment. To remove the rear

motor, remove the single large hex

screw using the supplied 3mm wrench. Then rotate the motor and

mount to the side of the model, and slide backward off the post.

The rear motor mount was carefully engineering to provide

additional features and adjustability. Two sets of holes are

provided for use with aftermarket motors. These use 3mm screws

with 25mm spacing that is compatible with most aftermarket

motors. These are:

1.

Low CG (center of gravity) installation

(mounts the motor low to the chassis

for best handling performance)

2.

High CG installation (mounts motor

higher for more clearance for larger

motors or aftermarket heat sinks)

An additional set of motor mounting

holes is included for custom application.

This is for larger aftermarket motors with

4mm screws and 29 - 30mm spacing.

Use higher viscosity

(thicker) diff oil for:

• More power to the wheels

with the most traction.

• Racing on low-traction

smooth surfaces .

• Better performance for

climbing on uneven terrain.

Using lower viscosity

(thinner) diff oil for:

• More power to the wheels

with least traction.

• Racing on low-traction

rough surfaces.

ADVANCED TUNING ADJUSTMENTS

Low CG

High CG

Big Motors

If you have questions or need technical assistance, call Traxxas at

1-888-TRAXXAS

(1-888-872-9927) (U.S. residents only)