32 • JATO 3.3

BASIC TUNING ADJUSTMENTS

2. Set the steering trim on the transmitter to neutral (zero).

3. Position the Jato so it is level and you

can view the installed steering servo

from the front.

4. Verify that the servo horn is positioned

so the arrow inscribed on the face points

straight up (see illustration).

5. If it is not, remove the servo horn (by removing the 3x6mm screw),

rotate it to the correct angle, (arrow pointing up), and reinstall.

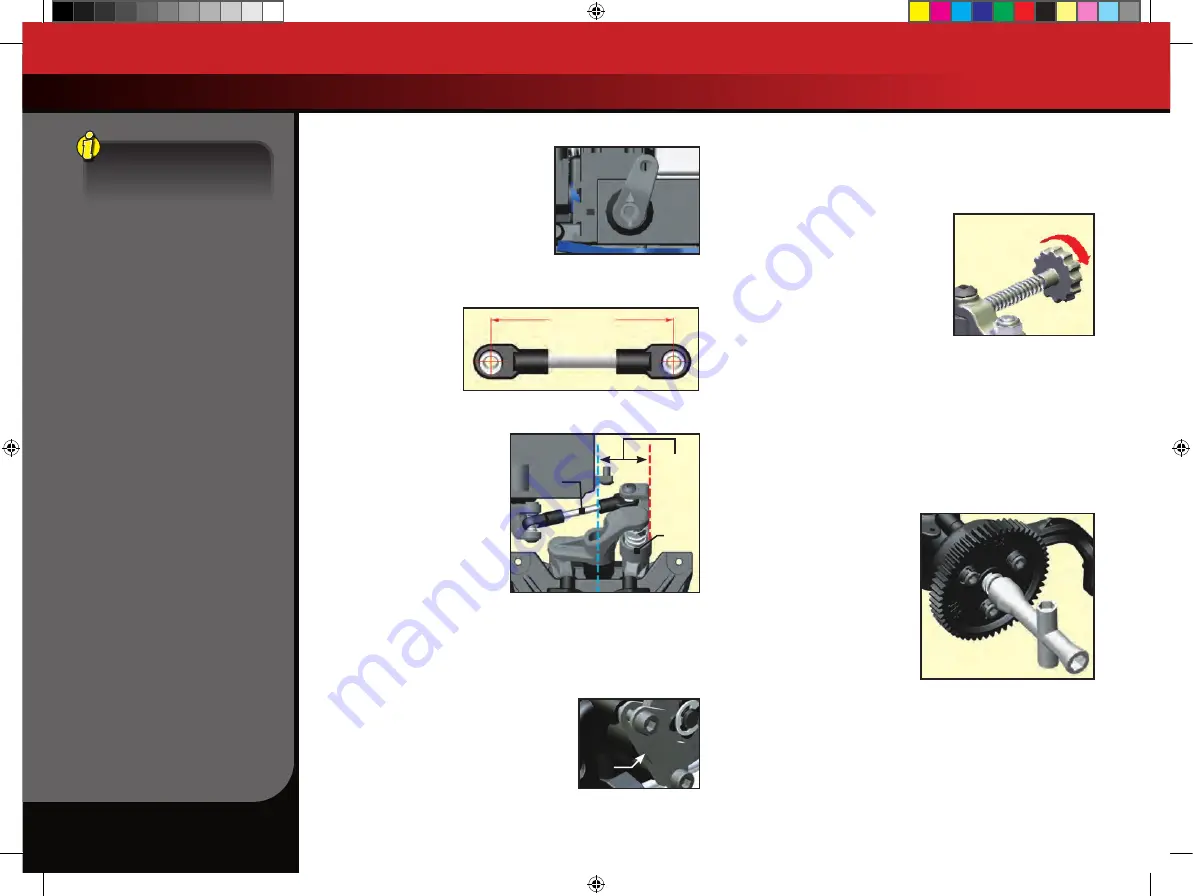

The steering servo link

must be assembled as

shown in the illustration

to the right. Note that the

rod end on one end of

the steering link is rotated

45 degrees compared the

other rod end. The exact

center-to-center distance between

the hollow balls is 43.1mm.

When the steering link is installed

in the Jato, the edge of the left

bellcrank (servo saver arm) should

be parallel to the centerline of the

vehicle (see illustration). If it is not

parallel, adjust the length of the

steering link.

BRAKE SETUP & ADJUSTMENT

Jato is equipped with an adjustable disc brake. The brake is preset at the

factory and should not require attention. As the brake material wears,

future adjustments may be necessary.

Brake Shoulder Screw Adjustment

The two shoulder bolts that are used to secure

the brake pads to the transmission housing

may need to be adjusted periodically as the

brake material wears down. They should be

tightened so an approximate 0.5mm (.020”)

gap exists between the disc and the brake pad

(on the transmission side). Adjust the brake by

first pushing the outer brake pad firmly against the inner pad with your

finger, sandwiching the brake disc between the brake calipers. Tighten

the brake shoulder bolts until they just barely touch the brake pads. Do

not over tighten these fasteners or you may damage the brake disc or

pads. Loosen each of the shoulder bolts by 1 turn.

Brake Linkage Adjustment

When correctly adjusted, the brake linkage

spring should barely touch the rod guide

when the servo is in neutral position (radio

system on, closed throttle). This will ensure

no brake drag during operation of the

vehicle. The brake adjustment knob can

be turned counter clockwise away from the

spring for less braking power if desired. Do not adjust the knob to apply

pressure against the spring while the servo is in the neutral position. This

will induce brake drag and cause undesirable handling.

Brake Pad Wear and Replacement

During normal use, the brake disc wears at a slow rate. If the disc wears

down to about 1.8mm in thickness, it should be replaced. Any more

wear than this could cause damage to the brake parts and improper

operation of the brake system.

TRANSMISSION TUNING

Adjusting the Slipper Clutch

Your Jato is equipped with an

adjustable Torque Control

™

slipper clutch. The slipper clutch is

integrated into the main spur gear

on the transmission (see page 6).

The slipper clutch is adjusted by

loosening or tightening the spring-

loaded locknut on the slipper shaft.

Use the supplied 4-way wrench. To

tighten or loosen the slipper nut,

hold the spur gear to prevent it

from turning and turn the adjustment nut. Turn the adjustment nut

clockwise to tighten (less slippage) and counter-clockwise to loosen

(more slippage). The slipper clutch has two functions:

1. Limiting the engine’s torque output to the wheels to prevent

wheelspin on low-traction surfaces and uncontrolled wheelies on

high-traction surfaces.

Steering Link Length Template

(actual size)

43.1mm

Servo

Saver

Arm

Steering

Link

Parallel

Less Brake

Brake

Linkage

Spring

.5mm

gap

Optional servo horns are

available separately for use

with non-Traxxas servos.

55077-KC2104-R00-Jato-33-Owners.indd 32

6/6/14 11:53 AM