RADIO SYSTEM ADJUSTMENTS

Throttle Neutral adjust

The throttle neutral adjustment

is located on the transmitter

face and controls the forward

and reverse travel of the throttle

trigger. There are two settings,

50/50 which allows equal travel

for both forward and brake, and

70/30 which allows more travel

for throttle and less for brake.

Change the adjustment by

pressing the button and sliding it to the desired position. 70/30 is

the recommended setting while running the Nitro Sport.

Servo Reversing Switches

On the front of the transmitter there are two switches. One for

throttle and one for steering. Moving the switches reverses the

direction of the corresponding servos. For example, if you turn your

steering wheel right and the model moves left, then switch the

steering servo reversing

switch to correct the

servo direction. You

may need to adjust

the corresponding

trim control after

moving the servo-

reversing switch.

TOTAL TRIGGER

MOVEMENT

50%

REVERSE

50%

FORWARD

4

INSTALLING RECEIVER BATTERIES

The receiver battery holder is located

underneath the battery cover. Remove

the battery cover by removing the

two body clips from the posts on both

sides of the battery holder.

Install 4 AA batteries into the battery

holder. Alkaline batteries should be

used. Place the

battery holder into

the battery cover

with the cushioning

foam. Secure the

battery cover to the

chassis using the two

body clips as shown.

ANTENNA SETUP

Locate the plastic tube and the

antenna tip (supplied in the bag

with your instructions). Insert the

black antenna wire, extending

from the receiver housing, into

one end of the tube and push it all

the way through. Spray the wire

with glass cleaner to make it easier

to insert. Insert the tube into the antenna mount on the side

of the chassis. Fold the remaining antenna wire over the top

of the antenna tube and secure it with the vinyl antenna tip.

Under no circumstances should you ever cut your antenna wire.

Its length is specially tuned to the frequency band, and cutting it

could severely shorten the radio’s range. On the transmitter,

fully

extend

the chrome telescopic antenna.

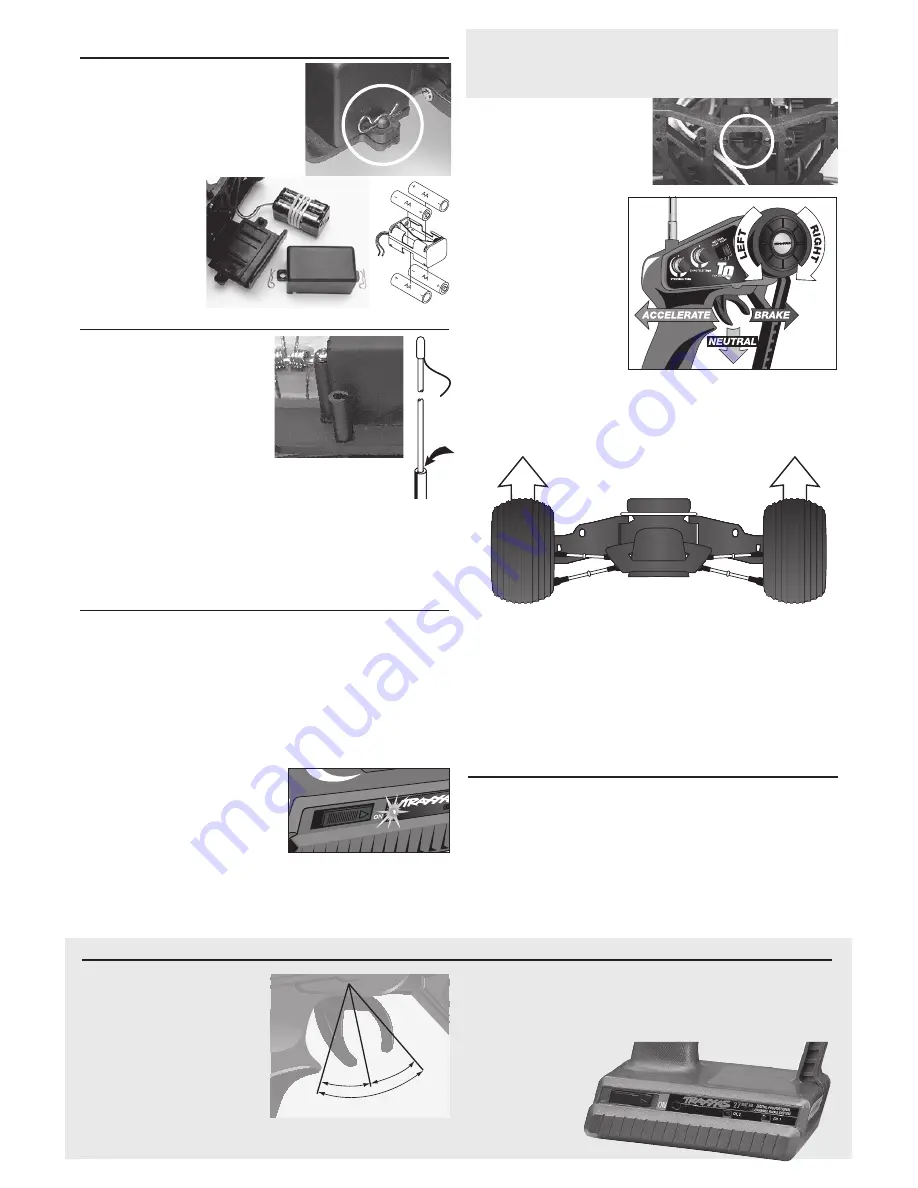

RADIO SYSTEM OPERATION

Your radio system was pre-adjusted before it left the factory, however,

the adjustment should be checked prior to running the truck.

1.

Before you ever turn your radio system on, you must “clear” your

frequency. There are six different channels numbered 1 through 6.

Each of the six channels is represented by a color. Look at the crystal

in the back of the transmitter to determine which of the channels

your truck is operating. Clearing your frequency means checking to be

sure that no one else in the area is operating on the same channel.

2. always turn the transmitter

on first and off last.

This

will prevent the model from

receiving stray signals and

running out of control. Slide the

transmitter switch to the “on”

position. A steady red light should

illuminate.

a flashing red

light indicates weak batteries

.

Weak batteries will limit the range

of the radio signal between your transmitter and receiver. Loss of

the radio signal can cause you to lose control of the truck.

3.

Turn the truck on. The

switch is located on the

chassis. The servos should

jump and move to their idle

(neutral) positions.

4.

With the front wheels

off the ground, operate

the steering control

on the transmitter

(channel 1). Check for

rapid operation of the

steering servo and that

the steering mechanism

is not loose or binding.

If the servo operates

slowly, check for weak

batteries. Turn the

“steering trim” control on the transmitter to adjust the servo so

that the front wheels are pointing straight ahead. Check to be

sure that the wheels do not turn more in one direction than in

the other.

5.

Operate the throttle trigger on the transmitter to ensure that

the throttle servo is operating properly. When the servo is

in the neutral position, the carburetor should be in its idle

position (you will adjust the engine idle speed later). When the

throttle trigger is pulled all of the way, the carburetor should

be in the fully-open position. When the throttle lever is pushed

forward, the brake should be locked and the throttle should

not close any further than when at idle.

RANGE TEST THE RADIO

There are many things such as buildings, power lines, radio

transmitters, etc. which can adversely affect the performance of

your radio system. To make sure you do not have a “runaway”

model, range test the radio system. With the radio system on and

working, hold the truck and have a friend carry the transmitter

away from you the distance you plan to run the truck. Have the

friend operate the controls on the transmitter to be sure that

everything is working at full range.

CH.2

CH.1

NOTE:

Never turn the transmitter or receiver off while the engine is

running. The model could run out of control. (The on/off switch

only turns the receiver on and off. It does not turn off the engine.)

CH.2

CH.1

0

°

0

°

1

°

-2

°

1

°

-2

°

-1

°

-1

°