Revo 3.3

•

33

push rod comes installed in the inner hole of the lower suspension

arm’s push rod mount. If the push rod is mounted in the outer hole,

the ride height decreases.

The ride height can be finely

tuned by adjusting the sag

of the suspension.

Do not

attempt to make large

changes to the ride height

by adjusting the spring pre-

load on the shock bodies.

If

suspension sag is severe and

requires a large increase of the spring pre-load to compensate, then a

firmer spring should be used. The lowest ride height can be achieved

by removing the blue spacers from the push rod and installing the

push rod in the outermost hole of the lower suspension arm’s push

rod mount.

The optional included Long Travel rocker arms are designed to be

used only with the push rods installed in the hole labeled “LT” (the

middle hole of the lower suspension arm’s push rod mount). Any

minor adjustments to the ride height are accomplished by adjusting

the spring pre-load.

Adjusting the Pivot Ball Caps

The pivot ball caps should be

adjusted so that the pivot balls

operate freely in the axle carriers

with no excess play. Use the

provided four-way suspension

multi-tool to tighten or loosen the

pivot ball cap.

Shock Oil

The 4 oil-filled aluminum shocks (dampers) effectively control the

suspension movement by preventing the wheels and tires from

continuing to “bounce” after rebounding from a bump. Changing the

oil in the shocks can vary the suspension damping effect. Changing the

oil to a higher viscosity oil will increase damping. Lowering the viscosity

of the oil will cause the suspension damping to be reduced. Damping

should be increased (with higher viscosity oil) if the model is bottoming

easily over jumps. Damping should be decreased (with thinner viscosity

oil) if the model is hopping over small bumps and feels unstable. The

viscosity of shock oil is affected by extremes in operating temperature;

an oil of certain viscosity will become less viscous at higher

temperatures and more viscous at lower temperatures. Operating in

regions with cold temperatures may require lower viscosity oil. From

the factory, the shocks are filled with SAE-30W silicone oil. Only use

100% silicone oil in the shock.

Replacing Shock Oil

The shocks have to be

removed from the vehicle and

disassembled to change the oil.

1.

Remove the lower spring

retainer and shock spring.

2.

Remove the upper shock cap

using the shock wrench and

the suspension multi tool

3.

Empty the used shock oil from the shock body.

4.

Fill the shock with new silicone shock oil up to the top of the

shock body.

5.

Slowly move the piston up and down (always keeping it submerged

in oil) to release the air bubbles. Let the shock sit for a few minutes

to allow any remaining air bubbles to surface.

6.

Slowly thread the upper cap with the installed shock bladder onto

the shock body with the suspension multi tool. The excess oil will

bleed out of the small hole in the shock cap.

7.

Tighten the shock cap until snug. Use the included steel shock

wrench to hold onto shock body while tightening.

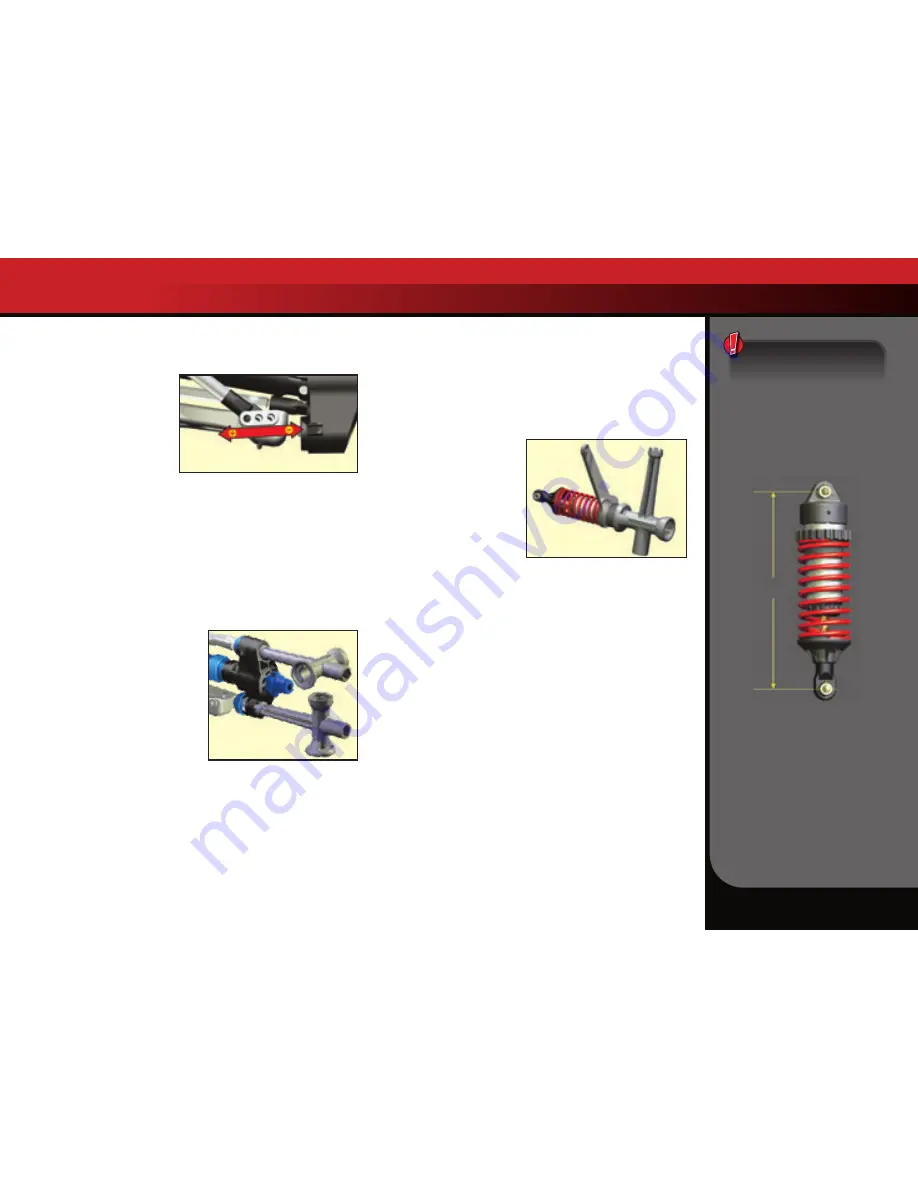

Important:

The shocks are

assembled at the factory

with a center-to-center

distance (between the rod

end balls) of 87mm. Any time

the shocks are removed and

disassembled, this distance

should be checked to ensure

proper operation of the

suspension.

87mm

Increases

Ride Height

Decreases

Ride Height

BASIC TUNING ADjUSTMENTS