14 • REVO PLATINUM EDITION

To further alter the characteristics of the variable

rate, the diameter of the bypass holes may be fine

tuned by enlarging them - speeding even further

the rebound rate. Optional pistons with bypass

holes that are larger or smaller (1, 2, or 3) than

the factory installed stock pistons can be used to

decrease or increase damping respectively.

From the factory, the shocks are filled with

SAE-50W silicone oil. Only use 100% silicone oil

in the shock. The stock Revo is equipped with #2

pistons front and rear.

Shock disassembly

The shocks must be removed from the vehicle and disassembled to change

the pistons. Use the shock exploded views included with the model to aid

in the assembly process.

1.

Remove the spring and lower spring

retainer from the shock.

2.

Remove the shock cap (A) and empty

the shock body of shock oil.

3.

Remove the lower cap (B) and

the X-ring from the shock body.

4.

Use side cutters to grip the shock shaft

just above the rod end (C). Remove the

rod end from the shock shaft using the

suspension multi tool (C).

5.

Remove the shock shaft with piston

from the shock body out through

the top of the shock body.

Shock assembly

1.

Replace the stock piston with desired

optional piston. Be careful not to lose

the thin steel valve or the small washer

located below the piston.

2.

Position the new piston onto the shock

shaft above the small washer. Grip the

threads of the shaft with side cutters

or needlenose pliers and tighten the

nut with the 4-way wrench to secure the

assembly.

Only tighten the nut enough to

remove vertical “play” of the piston. Over

tightening the nut will deform the steel

valve and cause the shock to malfunction.

The piston should be free to rotate on the

shaft when tightened.

3.

Insert the shock shaft assembly through the

shock body until the piston bottoms out.

4.

Lubricate the shaft and X-ring with silicone oil.

5.

Install the X-ring over the shaft and into the

bore of the shock body.

6.

Install the lower cap using the suspension

multi tool (B).

7.

Slide the bump stop onto the shaft.

8.

Grip the shaft close to the threads with needle nose pliers or side

cutters and thread the rod end onto the shock shaft until the rod end

bottoms out (C).

9.

Fill the shock with new silicone shock oil up to the

top of the shock body. Slowly move the piston up

and down (always keeping it submerged in oil) to

release the air bubbles. Let the shock sit for a few

minutes to allow any remaining air bubbles to

surface.

10.

Slowly thread the upper cap with the installed

shock bladder onto the shock body with the

suspension multi tool (A). The excess oil will bleed

out of the small hole in the shock cap. Tighten the

shock cap until snug. Use the included steel shock

wrench to hold onto shock body while tightening.

11.

Reinstall the spring and lower retainer.

TRANSMISSION AND DIFFERENTIAL TUNING

Adjusting the Slipper Clutch

Your Revo is equipped with an adjustable

Torque-Control

™

slipper clutch. The

slipper clutch is integrated into the

main spur gear on the transmission. The

slipper clutch is adjusted by loosening

the spring-loaded locknut on the slipper

shaft. Use the supplied 8mm open-end

metric wrench. To tighten or loosen the

slipper nut, insert the 2.0mm hex wrench

into the hole in the end of the slipper shaft. This locks the shaft for

adjustments. Turn the adjustment nut clockwise to tighten (less slippage)

and counter-clockwise to loosen (more slippage). The slipper clutch has

two functions:

1.

Limiting the engine’s torque output to the wheels to prevent

wheelspin on low traction surfaces and help to prevent damage

to the gears in the transmission during on-throttle landings.

2.

Protecting the drivetrain from sudden impact or shock loads (such as

landing from a jump with the engine at full throttle).

From the factory the slipper clutch is set for minimal slippage, just

enough to protect the drivetrain from shock loads. On slippery, low

traction surfaces such as a hard-packed, dry racetrack you may benefit

from loosening the slipper adjustment nut to allow for more clutch

slippage. This will make the truck easier and more forgiving to drive

by helping to reduce the amount of wheel spin. Loosening the slipper

adjustment can also improve performance on extreme high traction

surfaces by preventing the front end from lifting off of the ground when

accelerating. Make slipper adjustments in small 1/8 turn increments.

The maximum tight setting for the slipper is just at the point where

there is little or no tire slippage on a high traction surface such as carpet

or a prepared racetrack. The slipper should not be tightened to the point

that clutch slippage is completely eliminated. Do not overtighten the

slipper nut or you could damage the slipper bearings, pressure plates, or

other components.

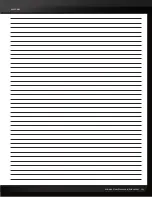

TUNING ADJUSTMENTS

87mm

Stock shock center-

to-center distance

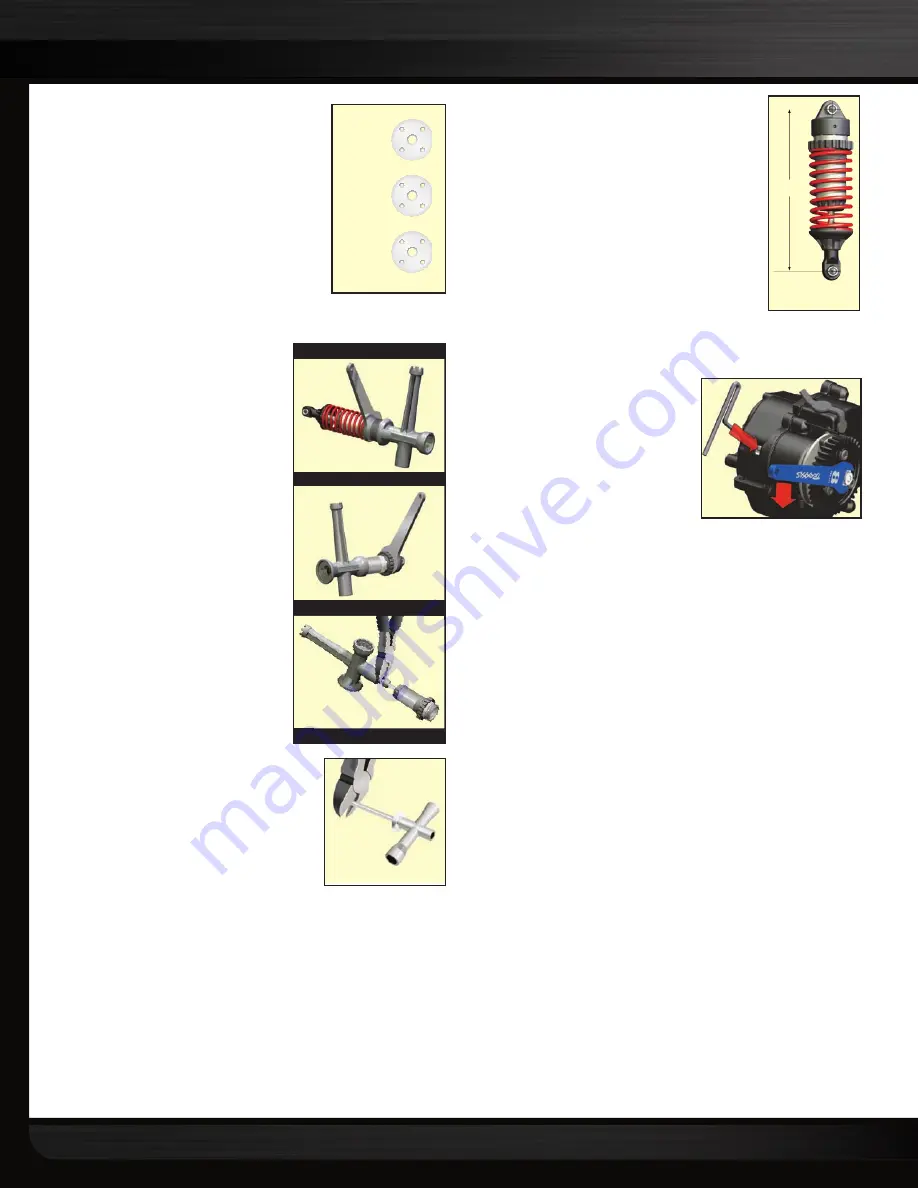

A. Tighten/Loosen Upper Cap

C. Remove/Install Rod End

B. Tighten/Loosen Lower Cap

Multi-tool Shock Functions

Piston Installation/Removal

2

2

2

1

1

1

3

3

3

Piston 1:

1.10 mm

Piston 2:

1.00 mm

Piston 3:

0.95 mm

Shock piston hole sizes

5304 Manual Work.indd 14

3/12/08 7:48:27 PM