44

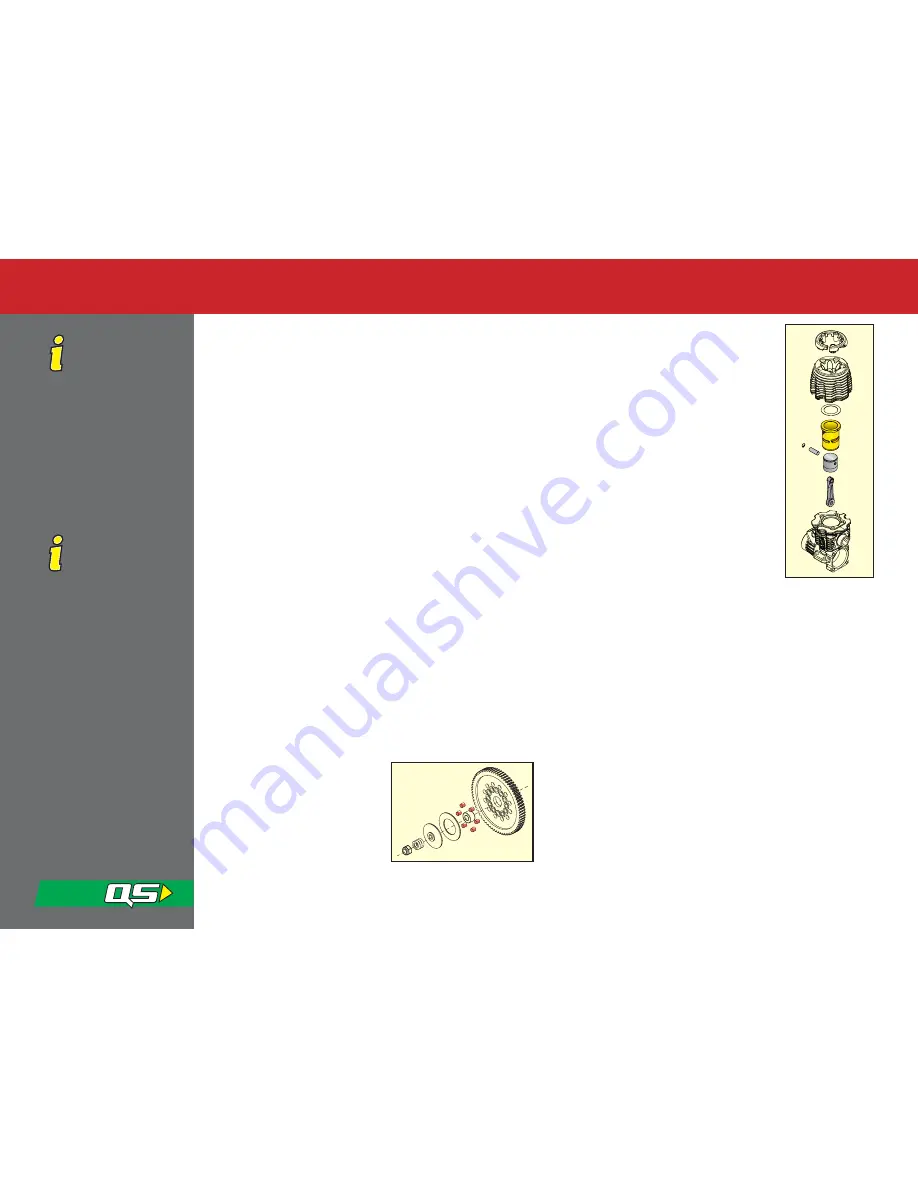

If the engine is worn or

damaged enough to

require replacing the

piston, sleeve, or

connecting rod, consider

exchanging your old

engine for a brand new

engine under the terms of

the Traxxas Lifetime Engine

Replacement Plan (ERP). It

could save you time and

effort. Details are in your

model’s documentation

package.

The TRX 2.5 is

designed to be easy to

rebuild. Critical engine

components such as the

crankcase, crankshaft, and

engine bearings are made

to extremely high quality

standards and should

under normal

circumstances outlast

multiple sets of pistons,

sleeves, connecting rods,

and wrist pins

(reciprocating assemblies).

It could be more

economical for you to

continue to use your good

bearings and crankshafts,

and simply replace the

reciprocating assembly as

needed. Engine assembly is

not difficult and replacing

the reciprocating assembly

does not require any

special tools or skills.

Your S-Maxx requires timely maintenance in order to stay in top

running condition.

Neglecting the maintenance could allow dirt,

deposits, and moisture to build up inside the engine leading to

internal engine failure.

The following procedures should be

taken very seriously.

After each hour of running:

Clean and re-oil the air filter. The instructions for this

procedure are on page 27.

We cannot stress enough the

value of cleaning your air filter at the scheduled intervals.

Do not neglect your air filter maintenance!

Clean the outside of the engine of accumulated dirt, oil, and

grime. Accumulated grime will decrease the engine’s ability to

cool itself.

After each running session:

Perform after-run maintenance on the engine. This clears the

engine of destructive moisture and other corrosive deposits.

This is extremely important for the life of the engine. See

page 45 for after-run maintenance procedures.

Inspect the vehicle for obvious damage or wear. Look for:

1.

Loose or missing screws

2.

Cracked, bent, or damaged parts

3.

Cut or loose wiring

4.

Cut or kinked fuel lines

5.

Signs of fuel leakage

Inspect the gears for wear, broken teeth, or debris lodged

between the teeth.

Other periodic maintenance:

Slipper clutch pegs

(friction

material): The slipper clutch

pegs will wear over time and

require replacement. The life of

the pegs depends on how the

slipper clutch was adjusted and

how the S-Maxx was used. If

the slipper will not tighten or you are seeing signs of wear on

the face of the gear, then the pegs should be replaced.

Piston/sleeve:

The life of the piston and

sleeve will vary greatly with how the

engine was used and maintained. The

piston and sleeve should be replaced

when they no longer seal effectively

(loss of compression). Symptoms include

the engine being difficult to start when

warm, stalling when warm, and stalling

when throttle is suddenly closed to idle.

Replace the wrist pin and G-clip

whenever the piston and sleeve are

replaced.

Connecting rod:

The connecting rod

should be replaced when the piston and

sleeve are replaced or after three gallons

of fuel, whichever comes first. Also

replace the piston wrist pin and G-clip

whenever the connecting rod is replaced. As with other

internal engine components, connecting rod life depends

engine’s usage and the quality and frequency of the

engine maintenance.

EZ-Start:

The cush drive elements in the EZ-Start drive

unit should be inspected after 3-gallons of fuel. If the cush

drive elements appear deformed or hardened they should

be replaced. Inspect the EZ-Start gears for any signs of

wear. Damaged gears should be replaced. Coat the gears

with a thin layer of white lithium grease.

▼▼

▼

▼▼

▼

▼

▼▼

Maintaining and Storing Your S-Maxx