24 • SLASH 4x4

ADVANCED TUNING ADJUSTMENTS

CAMBER GAIN

Slash 4x4 has provisions for adjusting the camber gain geometry of

the front and rear suspension. “Camber gain” refers to an increase in

camber angle as the suspension is compressed. The camber gain of the

vehicle can be changed by moving the camber link attachment to a

different horizontal mounting position. Adjusting the camber gain will

alter the tire contact patch as the suspension is compressed. Making

the camber link shorter will increase the camber gain. This makes

the vehicle more stable over bumps, but reduces traction on smooth

surfaces. Lengthening the camber links has the opposite effect.

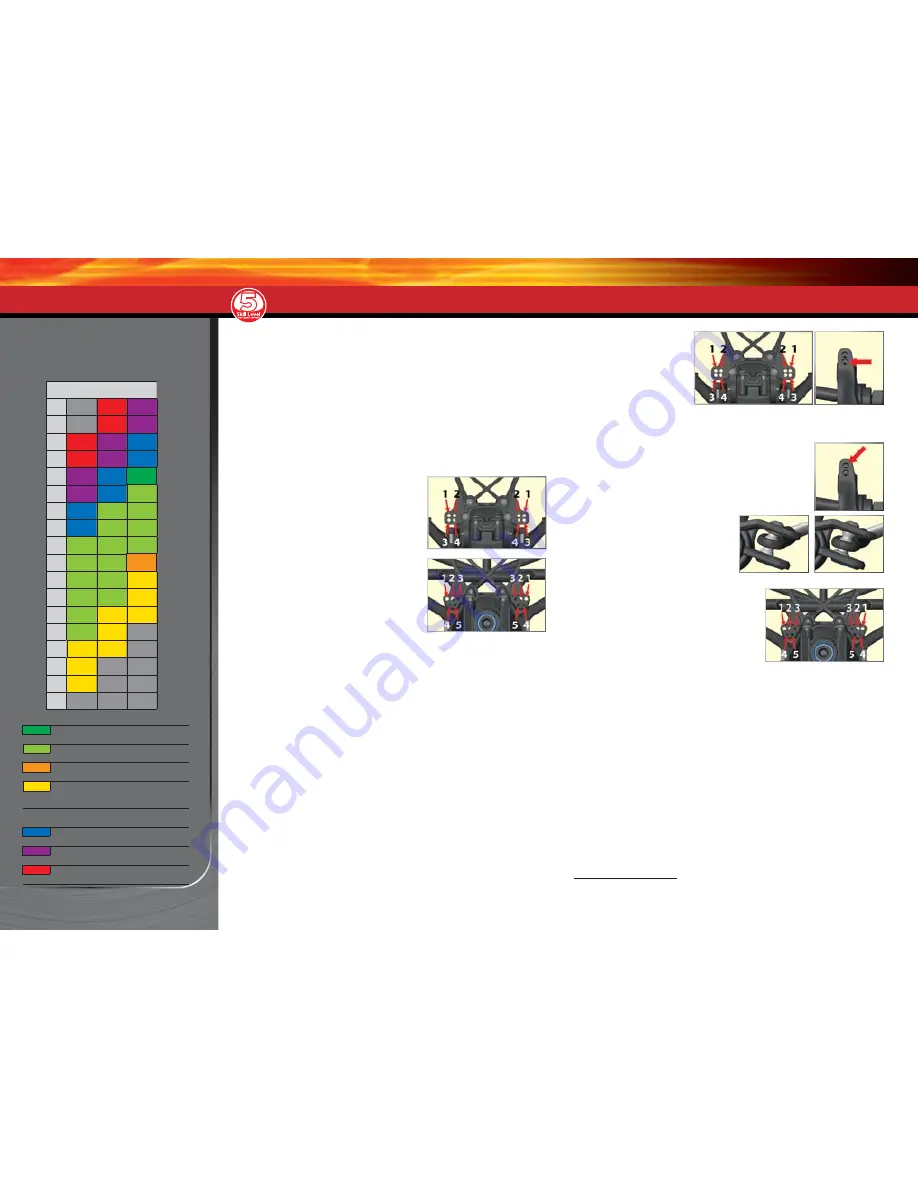

• Front Camber Gain

To increase the camber gain on the front

suspension, move the inner camber link

ends out to Position 3. Position 4 is the

stock setting.

• Rear Camber Gain

To increase the camber gain on the rear

suspension, move the inner camber link

ends out to a different attachment hole

(Position 1 or 2 in the image. Position 3 is

the stock setting).

Once you make adjustments to the camber

gain, you may need to re-adjust the static camber to suit

your tuning needs.

ROLL CENTER

Slash 4x4 has provisions for adjusting the roll center geometry of the

front and rear suspension. Roll center refers to the virtual axis around

which the chassis will roll when subjected to cornering forces. The roll

center of the vehicle can be raised by mounting the inner ends of the

camber links in a lower position. Raising the roll center will effectively

increase the roll stiffness of the vehicle (similar to installing swaybars).

Adding roll resistance to one end of the vehicle will tend to add traction

to the opposite end. For example, increasing roll resistance in the

rear will provide more traction for the front wheels and potentially

more steering. Raising the roll center on the front and rear equally will

increase overall roll resistance without changing the handling balance.

The default factory locations are designed to make the truck easier and

more forgiving to drive and less likely to traction roll in turns.

• Front Roll Center

To lower the roll center on

the front suspension, move

the inner camber link ends

up to a different attachment

hole (Position 1 or 2.

Position 4 is the stock setting). To lower the roll center further, move the

outer camber link ends to the lower position on the C-hub.

Bump steer correction

- “Bump steer” refers to

unwanted steering inputs caused by suspension

movement. Slash 4X4’s suspension geometry is

designed to minimize bump-steer. If you are using

the upper hole on the C-hub (image A) and either

of the two lower holes on the shock

tower (positions 3 or 4 in “Front”

image), the tie rod ball should be

oriented with the large flat end on

top (stock position - image B). When

using any other combination of

camber link attachment points, the tie rod

ball should be oriented with the large flat

end on the bottom (C).

• Rear Roll Center

To raise the roll center

on the rear suspension, relocate the inner

camber links to one of the two holes

(position 4 or 5 in image) in the lower row of the rear camber link

attachment, located near the base of the rear shock tower.

Once you make adjustments to the roll center, you may need to

re-adjust the static camber to suit your tuning needs.

GEARING

One of the more significant advantages to your model’s transmission

is the extremely wide range of available gear ratios. Changing the

gearing allows you to fine tune the speed of the model and control

the temperatures of the battery pack and motor. Use a lower gear

ratio (numerically larger) to reduce current draw and temperatures.

Use a higher gear (numerically lower) to increase top speed. Use the

following formula to calculate the overall ratio for combinations not

listed on the gear chart:

Front

Front

C-hub

Rear

Rear

B

C

# Spur Gear Teeth

x 2.85 = Final Gear Ratio

# Pinion Gear Teeth

Gearing Compatibility Chart:

The chart below shows

recommended gear combination

ranges for your model.

Spur Gear

Pinion Gear

50

52

54

9

-

16.44

17.08

10

-

14.80

15.37

11

12.94

13.45

13.97

12

11.86

12.33

12.81

13

10.95

11.38

11.82

14

10.16

10.57

10.98

15

9.49

9.87

10.25

16

8.89

9.25

9.61

17

8.37

8.71

9.04

18

7.91

8.22

8.54

19

7.49

7.79

8.09

20

7.12

7.40

7.68

21

6.78

7.05

7.32

22

6.47

6.73

-

23

6.19

6.43

-

24

5.93

-

-

25

5.69

-

-

26

-

-

-

Thick black border indicates stock settings.

A

Out of Box Setup, recommended for most

running, 6 or 7-cell NiMH, 2S LiPo

Recommended gear range for 6 or 7-cell

NiMH

Included optional gearing, for high-speed

running only

Fits, for high-speed runs only, not

recommended for use with NiMH batteries

High-current LiPo batteries required.

Requires removal or modification

of plastic motor end cap for proper fit

Requires removal or modification

of center shaft cover for proper fit

For aftermarket 540 motors; center

shaft cover removed or modified

Blue, purple, and red gearing ranges require part modification or the use of

aftermarket brushed 540 motors to accommodate the gearing selection