SLASH 4x4 • 25

ADVANCED TUNING ADJUSTMENTS

When using higher gear ratios, it is important to monitor the

temperatures of the battery and motor. If the battery is extremely

hot (150°F), and/or the motor is too hot to touch (200°F), your

model is probably over-geared and drawing too much current. This

temperature test assumes that the model is close to factory stock

weight and operates freely with no excessive friction, dragging, or

binding, and the battery is fully charged and in good condition.

Note

:

Check and adjust gear mesh if a spur and/or pinion gear is changed.

This model is equipped with a Velineon 3500 motor. The gear

combination that comes stock on each model provides good overall

acceleration and top speed. If you want more top speed install the

included optional large pinion gear (more teeth).

The included

optional large pinion gear is intended for high-speed running on

hard surfaces, and this gearing is not recommended for off-road or

repetitive starting and stopping.

LIPO BATTERIES

LiPo batteries are intended only for the most advanced users that are

educated on the risks associated with LiPo battery use. It is critical to

follow all instructions supplied by the battery manufacturer and the

charger manufacturer for proper charging, use, and storage of LiPo

batteries. Make sure you understand how to use your LiPo batteries.

See

Safety Precautions

and warnings on page 4 for more information.

ADVANCED VXL-3s ESC SETUP

The VXL-3s electronic speed control is capable of controlling brushed,

brushless, and sensored brushless motors. The VXL-3s auto-detects

the motor type and has numerous built-in safeguards to prevent

damage from mis-wiring or damaged wiring.

Sensorless Brushless Motors

Sensorless motors are the easiest and most reliable brushless motor

type. The VXL-3s is optimized to deliver the smoothest possible

sensorless motor performance. The Velineon 3500 is a sensorless

brushless motor (see sidebar for specs). The wiring (phase alignment)

of the motor determines its direction of rotation. Refer to the wiring

diagram on page 10.

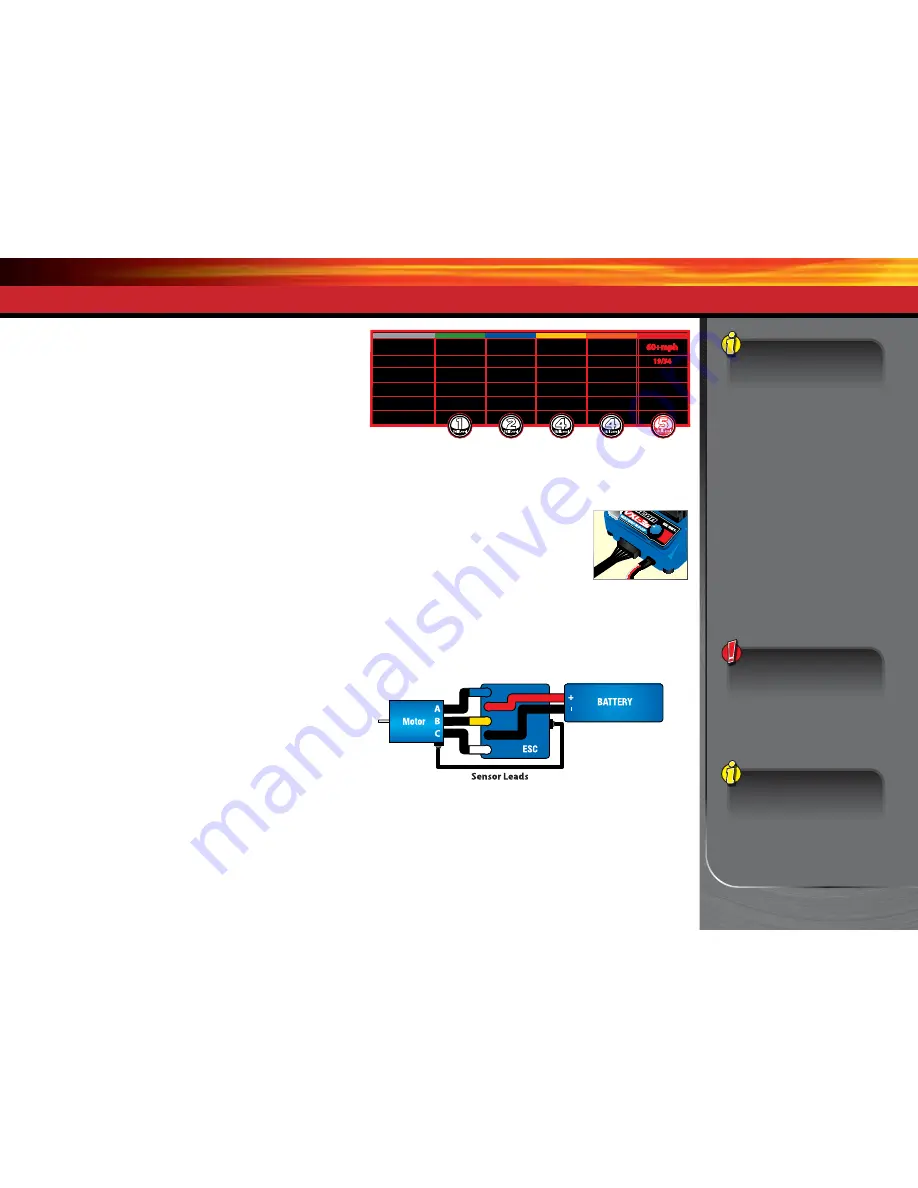

Sensored Brushless Motors

The VXL-3s is fully compatible with sensored brushless motors.

Sensor motors use an additional sensor installed in the motor to

communicate rotor position to the speed control. The VXL-3s features

a covered auxiliary port that accepts aftermarket motor sensors on

the front face of the unit.

The VXL-3s has built-in Sensor Motor Backup

Protection to prevent damage if the sensor

leads or phase leads become disconnected.

If a sensor lead becomes damaged or is

disconnected, the VXL-3s automatically

switches to sensorless brushless operation.

The VXL-3s also features Sensor Phase Detection. When a sensored

brushless motor is connected, the VXL-3s will check for proper wiring.

If the motor phase wiring is incorrect, the VXL-3s will not apply power

to the motor until it is wired correctly.

Optional sensored brushless motor wiring diagram

:

Brushed Motors

For the ultimate in versatility, the VXL-3s has no motor limit when

used with a brushed motor. This allows you to use any readily

available 540 or 550 size brushed motors in your VXL-3s equipped

vehicle. Always be sure to follow all break in and maintenance

instructions set forth by the motor manufacturer. The VXL-3s

Battery

Pinion/Spur

mAh

Skill Level

* Stock Gearing

** Included Optional Pinion

#6808

Slash 4x4

Nominal Voltage

60+mph

60+mph

35+mph

13/54*

7-Cell NiMH

8.4V

4000+ mAh

40+mph

18

/54**

7-Cell NiMH

8.4V

4000+ mAh

40+mph

19/54

2S LiPo

7.4V

4000+ mAh

45+mph

13/54*

3S LiPo

11.1V

5000+ mAh

19/54

19/54

3S LiPo

11.1V

5000+ mAh

Velineon 3500 Specs

Type:

Sensorless brushless

RPM/volt:

3500 (10-turn)

Magnet type:

Ultra High-Temperature

Sintered Neodymium

Connection type :

3.5mm bullet

Wire size:

12 Gauge

Current Ratings:

200A constant

320A peak/burst

Max RPM:

50,000

Diameter:

36mm (1.42) (540 size)

Length:

55mm (2.165)

Weight:

262g (9.24oz)

The VXL-3s features Locked

Rotor Protection. The VXL-3s

checks to make sure the

motor is turning. If the motor

is locked or damaged, the

ESC will enter fail-safe until

the motor is free to rotate.

Always use the proper length

motor bolts. The standard

motor mounting bolts

are 3x8mm. Using motor

bolts that are too long can

interfere with the motor’s

rotation and damage the

motor’s internals!