28 • SLASH 4X4 ULTIMATE

TUNING THE SEALED GEAR DIFFERENTIALS

The action of the Slash 4X4 Ultimate’s front and rear gear

differentials can be tuned for different driving conditions and

performance requirements, without major disassembly or removal

of the suspension system.

From the factory, the differentials are sealed to maintain consistent

long-term performance. Changing the oil in the differential with

either lower or higher viscosity oil will vary the performance

characteristics of the differentials. Changing to a higher viscosity oil

in the differential will reduce the tendency for motor power to be

transferred to the wheel with the least traction. You may notice this

when making sharp turns on slick surfaces. The unloaded wheels

on the inside of the turn have the least traction and tend to spin

up to extremely high rpms. Higher viscosity (thicker) oil causes the

differential to act like a limited-slip differential, distributing more

equal power to the left and right wheels.

Slash 4X4 Ultimate will generally benefit from higher viscosity oil

when climbing or racing on low traction surfaces.

Note

: Heavier oil

will allow power to be transferred even with one or more tires off

the ground. This can make the vehicle more likely to overturn on

high-traction surfaces.

From the factory, the front differential is filled with SAE 30,000W

(30K) viscosity silicone oil. The rear differential is filled with grease,

but can also be tuned with silicone differential oil. Only use silicone

oil in the differentials. Traxxas offers silicone differential fluid in a

variety of viscosities:

Part #5135: 10K

Part #5136: 30K

Part #5137: 50K

Part #5130: 100K Part #5039: 500K

Follow the steps below to access and refill the front and rear differentials:

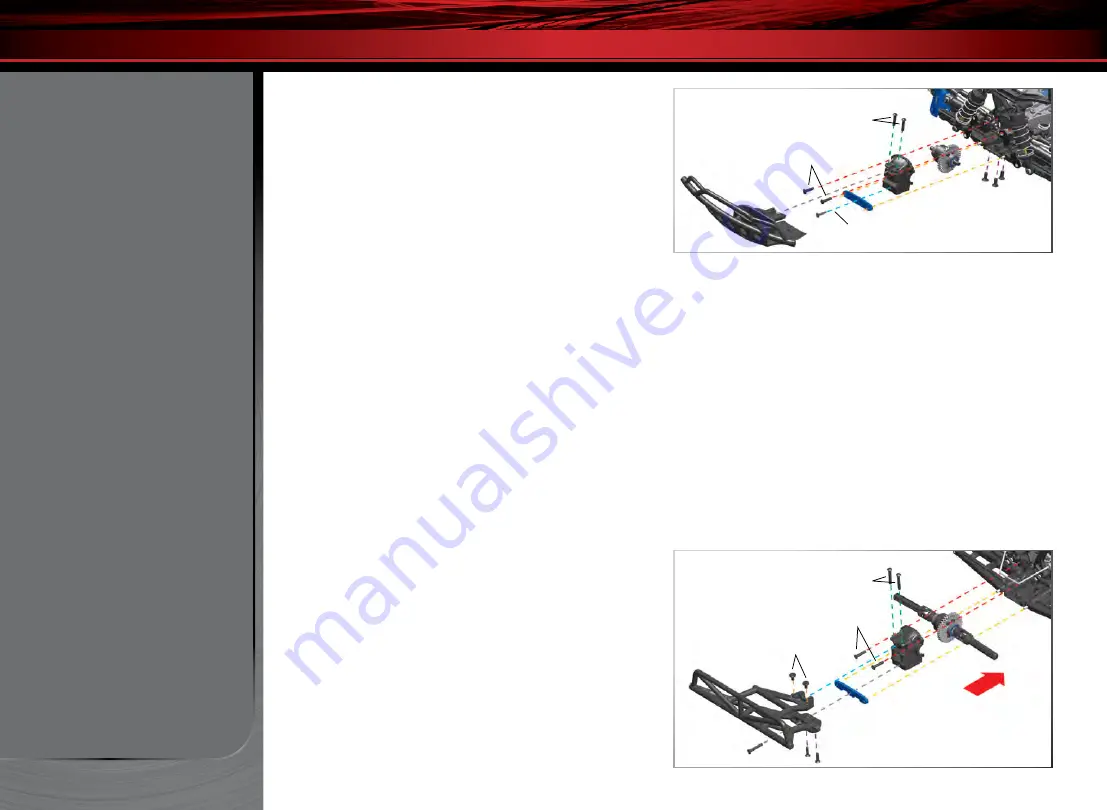

Front differential:

1. Remove the two 3x15mm button-head screws that secure the

top bumper mount to the differential

(

diff) case.

2. Turn the chassis over and remove the three 4x10mm

countersunk screws that hold bumper/skid plate to the bulkhead.

The two rear screws do not need to be removed.

3. Slide bumper assembly off of the chassis.

4. Remove 3x15mm button-head screw from diff tie bar.

5. Slide tie bar off truck.

6. Remove two 3x15mm button-head screws from the differential

cover. Do not remove the two screws that secure the shock tower.

7. Use a 1.5mm hex wrench to remove the two screw pins that

hold the driveshaft yokes to the differential output shafts.

Remove the differential cover and slide the differential out of the

front of the case.

8. To reinstall the differential, reverse the steps.

Rear differential:

1. Remove the two 3x6mm flat-head sway bar screws.

2. Remove the two 3x20mm button-head screws that secure the

top bumper mount to the differential case.

3. Turn the chassis over and remove the two 3x12mm countersunk

crews that hold the bumper/skid plate to the bulkhead. The two

front screws do not need to be removed.

4. Remove the 3x20mm button-head screw from the bumper

mount and tie bar.

ADVANCED TUNING ADJUSTMENTS

1.

3x15 BCS

2.

3x20 BCS

4.

3x15 BCS

5.

6.

3x15 BCS

7.

3x15 BCS

2.

4x10 BCS

3.

3x12 BCS

3.

4. 3x20 BCS

Front Differential Removal

Rear Differential Removal

5.

6.

Front of Truck

1.

3x6 FCS