20

•

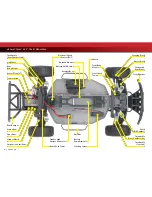

Slash

Adjusting Your Model

Adjusting the Slipper Clutch

The model is equipped with an

adjustable slipper clutch which

is built into the large spur gear.

The purpose of the slipper

clutch is to regulate the

amount of power sent to

the rear wheels to prevent

tire spin. When it slips,

the slipper clutch makes a

high-pitch, whining noise. Remove the rubber slipper clutch plug

on the transmission cover in order to adjust the slipper. Use the

4-way wrench to turn the adjusting nut clockwise to tighten and

counter-clockwise to loosen. Place the model on a high-traction

surface, such as carpet. Adjust the slipper so that you can hear it

slip for approximately two feet from a standing, full throttle start.

(Learn more about adjusting the slipper clutch in the sidebar.)

Motor and Gearing

There are two different types of aftermarket motor which can be

purchased for your model, stock and modified. Stock motor all

have the same wire thickness and number of turns around the

armature as governed by sanctioned racing organizations. They

are inexpensive, and widely available. Modified motor are more

expensive, may feature ball bearings and come in a variety of wire

thicknesses and number of turns of wire on the armature. The

fewer number of turns of wire on the armature, the more powerful

the motor will be. Keep in mind that the more powerful the motor,

the less battery run time you will have.

One of the more significant advantages to your model’s

transmission is the extremely wide range of available gear ratios. It

can be geared low enough to run extremely hot, modified motor.

Modified motor should be geared lower (higher numerically) than

stock motor because they reach their maximum power at higher

RPM’s. A modified motor that is geared incorrectly can actually

be slower than a correctly-geared, stock motor. Use the following

formula to calculate the overall ratio for combinations not listed on

the gear chart:

If you are worried that you might be over-geared, check the

temperature of the battery pack and motor. If the battery is

extremely hot, and/or the motor is too hot to touch, your model is

probably over-geared. If you are not able to run your model for at least

four minutes before the battery dies, then change to a lower gear

ratio. This temperature test assumes that the model is close to factory

stock weight and operates freely with no excessive friction, dragging,

or binding, and the battery is fully charged and in good condition.

The model is equipped with a Titan 12T 550 motor. The gear

combination that comes stock on each model provides good overall

acceleration and top speed. If you want more top speed and less

acceleration install the included optional large pinion gear (more

teeth). If you want more acceleration and less top speed, use a

smaller optional (not included) pinion gear.

The included optional

large pinion gear is intended for high-speed running on hard

surfaces, and this gearing is

not recommended for off-

road or repetitive starting

and stopping.

The Titan 12T is equipped

with an integrated cooling

fan that is effective during

medium to high-speed

operation. The gearbox is

specially vented to cool

the motor. Repetitive

starting and stopping over short

distances creates excess heat and

will not allow the fan to cool the

motor properly. For this type of

driving, smaller pinion gears are

recommended to reduce load on

the motor.

Gearing Compatibility Chart

The chart to the right shows a full

range of gear combinations. This

does NOT imply that these gear

combinations should be used. Over-

gearing (bigger pinions, smaller

spurs) can overheat and damage

the motor and/or speed control.

Items in black will fit 540 motor only

(not Titan 12T).

Tighten

Loosen

# Spur Gear Teeth

x 2.72 = Final Gear Ratio

# Pinion Gear Teeth

Spur Gear

Pinion Gear

83

86

90

15

15.04

-

-

16

14.12

14.63

-

17

13.27

13.76

14.39

18

12.54

13.00

13.60

19

11.89

12.32

12.89

20

11.28

11.69

12.24

21

10.75

11.14

11.66

22

10.25

10.63

11.12

23

-

10.17

10.63

24

-

-

10.20

540 motor only

Quick acceleration, less

top speed

Stock

Optimal Range

On-road only

On-road only,

7-cell maximum

• Fast Acceleration

• Short Distances

• Small Tracks

18-Tooth Pinion

90-Tooth Spur*

• Good Acceleration

• Good Speed

• Normal Conditions

18-Tooth Pinion

86-Tooth Spur

• High Top Speed

• Long Distances

• Hard Surfaces

23-Tooth Pinion

86-Tooth Spur

*optional (sold separately)

To achieve a good starting

point for the slipper clutch,

tighten the slipper clutch

adjusting nut clockwise until

the slipper clutch adjusting

spring fully collapses (do not

over tighten), and then turn

the slipper clutch nut counter-

clockwise one full turn.

Do not run your model with

the slipper clutch adjusting

spring fully compressed. The

minimum recommended

slipper clutch setting is 1/2

turn counter-clockwise from

fully compressed.