6) Operate the forward/reverse shift button on the transmitter.

With the shift button pushed down, the truck will only operate

in forward motion. Pushing up on the shift button shifts the

transmission into reverse. Check for normal operation of the

shifting servo. In reverse, the shifting servo should extend the

transmission shifter from the transmission housing.

PREPARING TO RUN

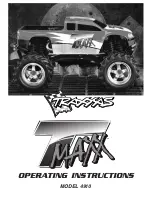

• INSTALLING THE EZ-START BATTERY

Use tie wraps to secure

a

fully-charged

7.2 volt

battery back to the

EZ-Start control box.

Plug the battery connec-

tor into the face of the

control box. The plug

will only go in one way.

• ANTENNA SETUP

Locate the plastic tube and

the antenna tip (supplied in

the bag with your instruc-

tions). Insert the black

antenna wire, extending

from the receiver housing,

into one end of the tube and

push it all the way through.

Insert the tube

into the antenna

mount on top of

the receiver

housing. Fold the

remaining antenna wire over the top of the

antenna tube and secure it with the vinyl

antenna tip. Under no circumstances should

you ever cut your antenna wire. Its length is

specially tuned to the frequency band, and

cutting it could severely shorten the radio’s

range. On top of the transmitter, fully extend

the chrome telescopic antenna.

GLUING THE TIRES

The truck tires should be glued to the rims to prevent

them from spinning inside the tire.

CAUTION: Wear eye protection

to prevent injury from glue

spattering into your eyes.

1. Glue the tires to the rim by

pulling the tire back from the rim

and placing a drop of thin CA

glue onto the bead.

2. Quickly re-seat the tire bead into the rim and allow to dry.

3. Repeat step 1 at several points around the tire until it is

secured to the wheel.

4. Allow the CA glue to completely cure before driving the vehicle.

NOTE: The acetone in finger nail polish remover should dis-

solve any glue that may come in contact with your fingers.

STARTING THE ENGINE

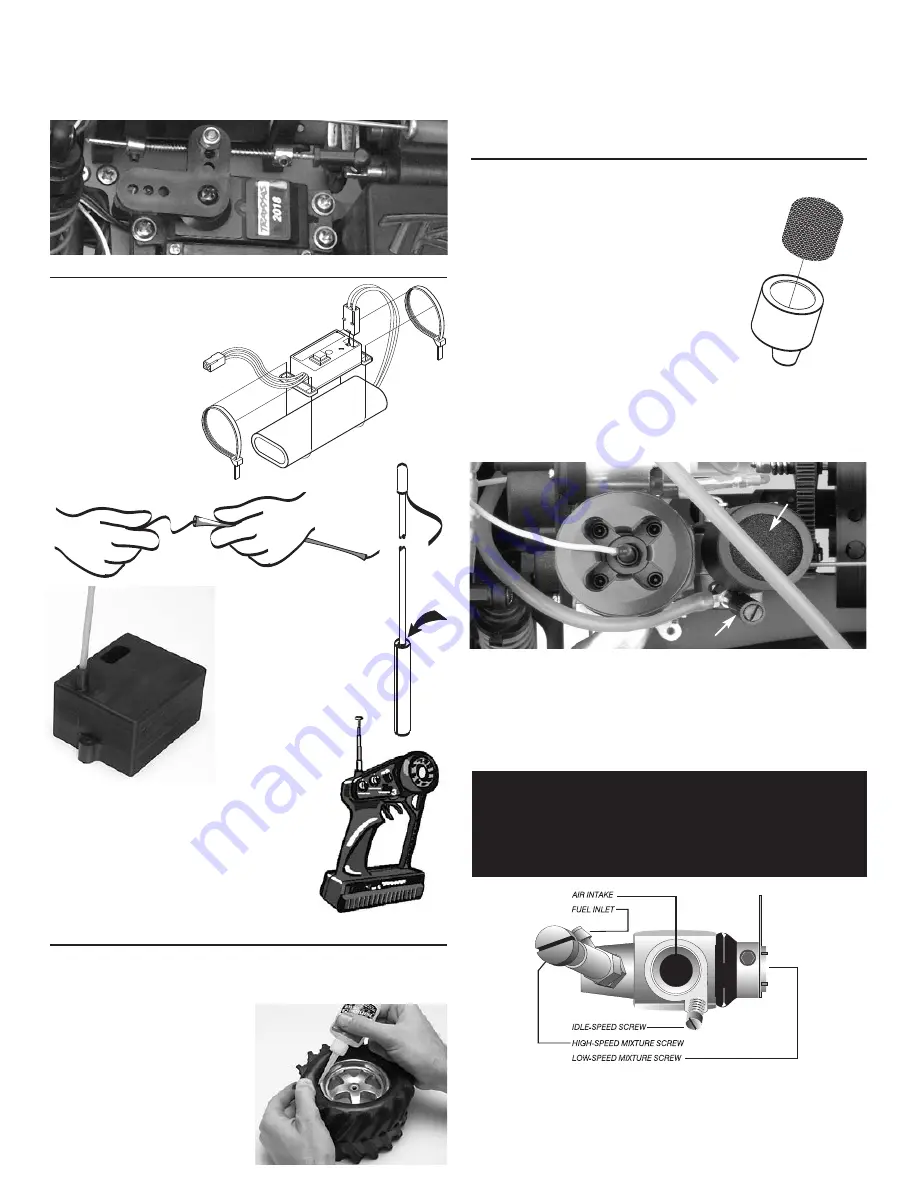

STEP 1: INSTALL THE AIR FILTER

Remove the protective cap from the car-

buretor air intake. Install the rubber air filter

base and pre-lubed foam element onto the

carburetor intake. The foam air filter ele-

ment may be cleaned and reused.

Always

be sure the filter element is oiled prop-

erly before running the engine.

For the

best filtration, use the type of oil made for

foam air filters. It should be available local-

ly from motorcycle shops and small

engine repair shops. Lightweight motor oil

or after-run oil may also be substituted. When the element gets

dirty, clean it with dish soap and rinse. Next, saturate it with oil

and then squeeze out the excess oil. For extremely dusty condi-

tions, special two or three-stage, pre-lubed filters are available

from Traxxas (Part #4062 and #4063).

STEP 2: FILL THE FUEL TANK

Use a small fuel bottle or bulb to put fuel into the tank. Only fill

the tank to the bottom of the fill neck. The T-Maxx can carefully be

refueled while the engine is running.

STEP 3: HIGH-SPEED MIXTURE SETTING

The high-speed mixture screw controls how much fuel enters

the engine during mid and high-speed operation. Turn the high-

speed mixture screw clockwise, by hand, until it stops

(Do not

tighten or the needle may be damaged).

Now, turn the mixture

screw counter-clockwise 2

1

/

2

complete turns.

AIR FILTER

HIGH SPEED NEEDLE

RECEIVER

HOUSING

Contact Traxxas for assistance: 1-888-TRAXXAS. 972-265-8000 (outside USA). E-mail us at support@Traxxas.com

5

Note: Your carburetor has been factory preset

for break-in. Do not readjust your carburetor

settings unless you suspect a problem. The

following steps are for reference only.