truck has poor acceleration but very high top speed, the

transmission is shifting into second gear almost instantly.

The shift point needs to be raised by turning the adjustment

screw clockwise.

• FORWARD TO REVERSE SHIFT ADJUSTMENT

Included on the TQ-3 transmitter is a forward/reverse shift button

which operates the channel 3, shifting servo. The forward/

reverse shift button has been pre-set at the factory to shift the

truck into reverse when the button is pushed up.

Do not attempt

to make adjustments to the shifter mechanism unless you

are experiencing a problem.

There is also a shifting trim

adjustment on the back of the TQ-3 transmitter. The trim adjust-

ment is factory pre-set for your convenience. You should not

have to make any adjust-

ments. If trim adjustments

for shifting become neces-

sary, insert a long small

screwdriver into the small

hole in the back of the

transmitter. Do not turn the

screwdriver more than 1/4

turn in either direction.

• TOE-IN

The T-Maxx comes from the factory with zero degrees of toe-in in

the front and one degree of toe-in in the rear. You can adjust the

toe-in on the front and rear of the truck. Set the steering trim on

your transmitter to neutral. Now, adjust your steering turnbuckles

so that both front wheels are pointing straight ahead and are par-

allel to each other (0 degrees toe-in). This will ensure the same

amount of steering in both directions. Adjust the rear toe control

links so that the rear wheels have 1˚ of toe-in.

• CAMBER

There are two pivot balls which are accessible through the

spokes of each of the wheels on the T-Maxx. From the factory, the

pivot balls are completely tightened into the suspension arms which

gives each of the wheels -1˚ of

camber. Loosening the bottom

camber pivot ball with a 2.5mm

Allen wrench will increase the

wheel’s negative camber. You

should not adjust the top pivot ball.

Loosening the top pivot ball will

increase positive camber and will

also change the wheel’s toe-in.

After running the truck, always

remember to check the front pivot

balls to make sure they are tight.

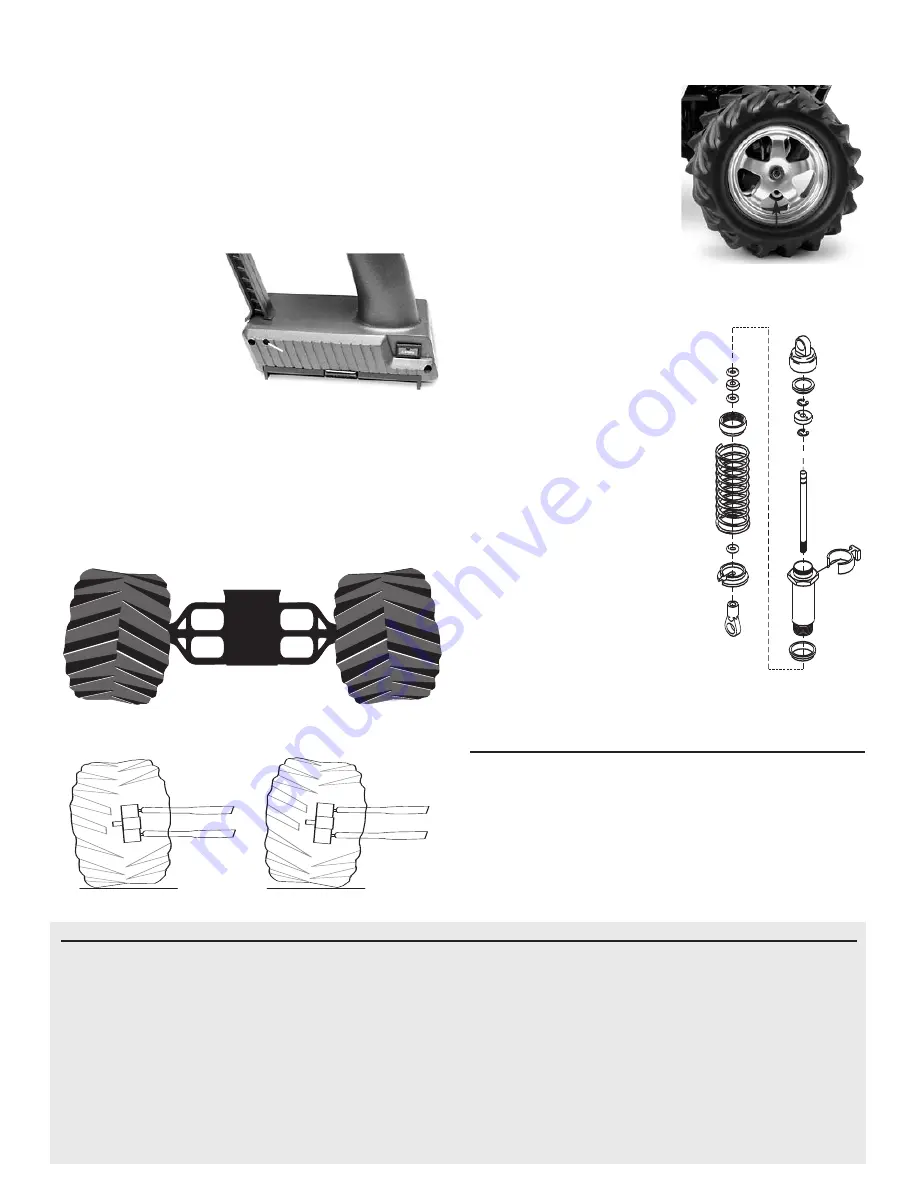

• SHOCKS

The eight dampers (shocks) on your

T-Maxx have the most influence on its

handling. Whenever you rebuild your

shocks, or make any changes to the

pistons, springs or oil, always do it care-

fully and in sets (front or rear). Piston

head selection depends on the range of

oil viscosities that you have available.

For example, using a two-hole piston

with a lightweight oil will give you the

same dampening as a three-hole piston

with heavier oil. We recommend using

two-hole pistons with a range of oil

viscosities from 10W to 40W (available

from your hobby shop). The thinner

viscosity oils (30W or less) flow with

less resistance and provide less

dampening, while thicker oils provide

more dampening. Use only 100% pure

silicone shock oil to prolong seal life.

The ride height for the T-Maxx can

be adjusted by adding or removing the

clip-on spring pre-load spacers. Note

that changes in ride height will occur

when the changes in damper angle or

spring rates are made. You can compensate for ride height

changes by changing the pre-load spacers on the dampers.

STORAGE

After running your T-Maxx, use a good “after-run” product prior

to storage. The chemicals used in the fuel attract moisture and

can cause moisture and corrosion to form inside the engine.

Drain the fuel tank, start the engine and run it until all of the

remaining fuel is completely used up. Remove the air cleaner

and place the recommended number of drops (usually 6 drops)

of the after-run oil into the carburetor. Now, spin the engine for 2-3

seconds with the EZ-Start to circulate the oil. Replace the air

cleaner.

Never store your T-Maxx with unused fuel in it.

PRE-LOAD

SPACERS

MAINTENANCE

1) Check the wheels and steering fr binding. Check the operation

of the shock absorbers.

2) Check the wiring for any frayed wires or loose connections,

including the wires on the EZ-Start quick connector. Fraying

or melting of the blue wire on your EZ-Start system can

cause your glow plugs to immediately short out.

3) Check the tightness of the grub screws in the collars on the

throttle and steering linkages.

4) Check the tightness of the front pivot balls.

5) Check the mounting of the receiver and servos.

6) Check the tightness of the wheel nuts with a wrench.

7) Check the fuel tank and all hoses for signs of leaks.

8) Check the operation of the radio system, especially the

condition of the batteries.

9) Check the exhaust system for leaks, cracks, or tears. Do not

run the car if there are any exhaust leaks.

10) Use Traxxas Nitro Wash spray cleaner to keep the T-Maxx

clean of accumulated dirt and oil. Do not spray any radio

components with Nitro Wash. Do not spray Nitro Wash into

a dirty air filter while it is installed on the engine.

11) The steering servo saver will wear out over time. If the

steering becomes loose, the servo saver should be replaced.

Positive camber

Negative camber

Toe-in

CAMBER PIVOT

BALL

Shifting Trim

Contact Traxxas for assistance: 1-888-TRAXXAS. 972-265-8000 (outside USA). E-mail us at support@Traxxas.com

8