20

•

XO-1

Once you become familiar with driving your model, you might need

to make adjustments for better driving performance

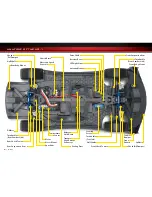

Adjusting Gear Mesh

Incorrect gear mesh is the most common cause of stripped spur

gears. Gear mesh should be checked and adjusted anytime a gear

is replaced, or if excessive gear noise is heard. To adjust gear mesh,

follow these steps:

1. Remove the right rear wheel using the supplied 17mm wheel wrench.

2. Loosen the two 3x15 motor-mount cap screws.

3. Using your 1.5mm hex driver, turn the mesh-adjustment set screw

counterclockwise to tighten the gear mesh. If needed, apply

gentle pressure to the motor to help the pinion slide closer to the

spur gear for a ‘tighter’

gear mesh. Turn the

set-screw clockwise to

move the pinion away

from the spur gear

to ‘loosen’ the gear

mesh. When properly

set, there should be

just a ‘tick’ of free play

between the pinion

and spur gears.

4. Tighten the two 3x15 motor-mount cap screws to hold the adjustment.

Tip: a strip of notebook paper can be inserted between the pinion

and spur gears to help set gear mesh. Before tightening the motor-

mount screws, insert the paper strip between the pinion and spur

gear. Adjust the pinion so it is completely meshed with the spur

gear, then tighten the motor mount screws. When the paper is

removed, you should have the required ‘tick’ of free play.

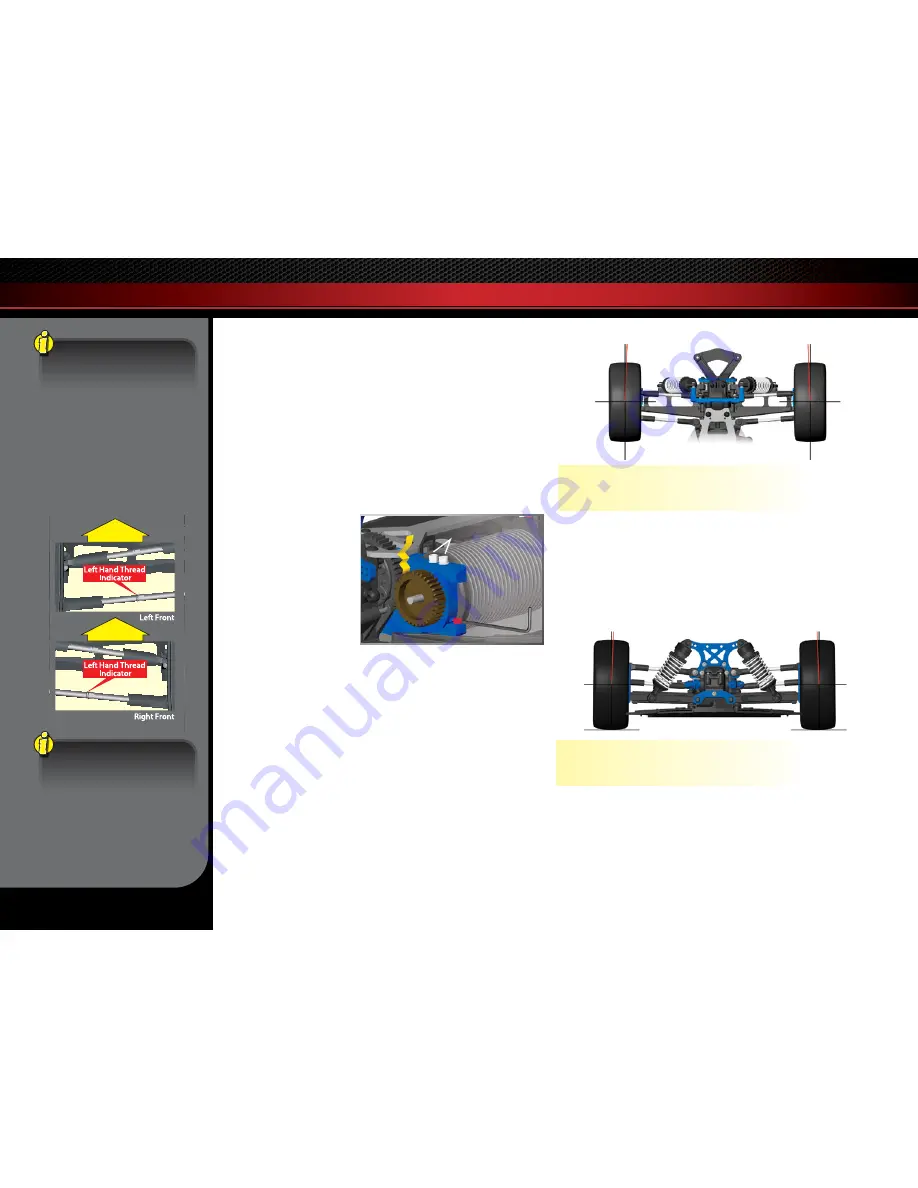

Adjusting the Toe-in

Geometry and alignment specs play an important roll in your

model’s handling. Take the time to set them correctly. Set the

steering trim on your transmitter to neutral. Now, adjust your servo

and tie rods so that both wheels are pointing straight ahead and are

parallel to each other (0° toe-in). This will ensure the same amount

of steering in both directions.

For increased stability, add 1°- 2° of toe-in to each front wheel. Use

the turnbuckles to adjust the alignment.

Adjusting the Camber

The camber angle of both the front and rear wheels can be

adjusted with the camber links (upper turnbuckles). Use a square or

right-angle triangle to set the camber accurately. Adjust the front

wheels to 1°- 2° of negative camber. In the rear, adjust the wheels

to 1°- 2° of negative camber. These adjustments should be set with

the model positioned at its normal ride height.

Springs

The front and rear springs on the model have identical spring

rates. The springs’ pre-load can be adjusted by turning the spring

pre-load adjuster. Adjusting the pre-load changes the ride height.

Adjust the pre-load so that the ride height at the front of the model

is 15mm, and the ride height at the rear of the model is 18mm.

BASIC TUNING ADJUSTMENTS

Camber

Toe-in

1°-2°

1°-2°

1°-2°

1°-2°

All of the toe links are

installed on the model so the

left-hand thread indicators

point to the same direction.

This makes it easier to

remember which way to

turn the wrench to increase

or decrease toe link length

(the direction is same at all

four corners). Note that the

groove in the hex indicates

the side of the toe link with

the left-hand threads.

Rear toe can be adjusted

by flipping the rear carriers

left to right, and vice versa.

Stock configuration is 3.5°

of toe-in. In the optional

position, toe-in is 1.5°.

Front of Model

Front of Model

Factory Toe-In Settings

Front:

1°

Rear:

3.5° toe-in each side

Factory Static Camber Settings

Front:

1° negative camber each side

Rear:

3.5° negative camber each side

Loosen

Screws

Strip of

Paper

1.5mm

Wrench