FACEM SPA - TURIN (TO) ITALY

BONE SAW

P. 80 of 97

USER AND MAINTENANCE MANUAL 1.0

Cleaning

General considerations

Cleaning is considered routine maintenance. These are regular or repeated activities of

elementary maintenance which do not generally require qualifications, authorisation(s) or

special tools.

Cleaning is an operation carried out with the machine disconnected from the

mains supply.

Take advantage of cleaning operations to inspect the machine and to check its

conditions.

Cleaning must always be carried out:

⇒

after each use. The functionality and durability of the machine also

depend on how it is kept.

⇒

possibly during use, if it is deemed necessary.

The machine does not use hazardous substances; the cleaning of its parts is possible by

following the procedures in this chapter.

The machine has no acute angles, sharp edges or rough surfaces, within the limits

permitted by their functions, likely to cause injury.

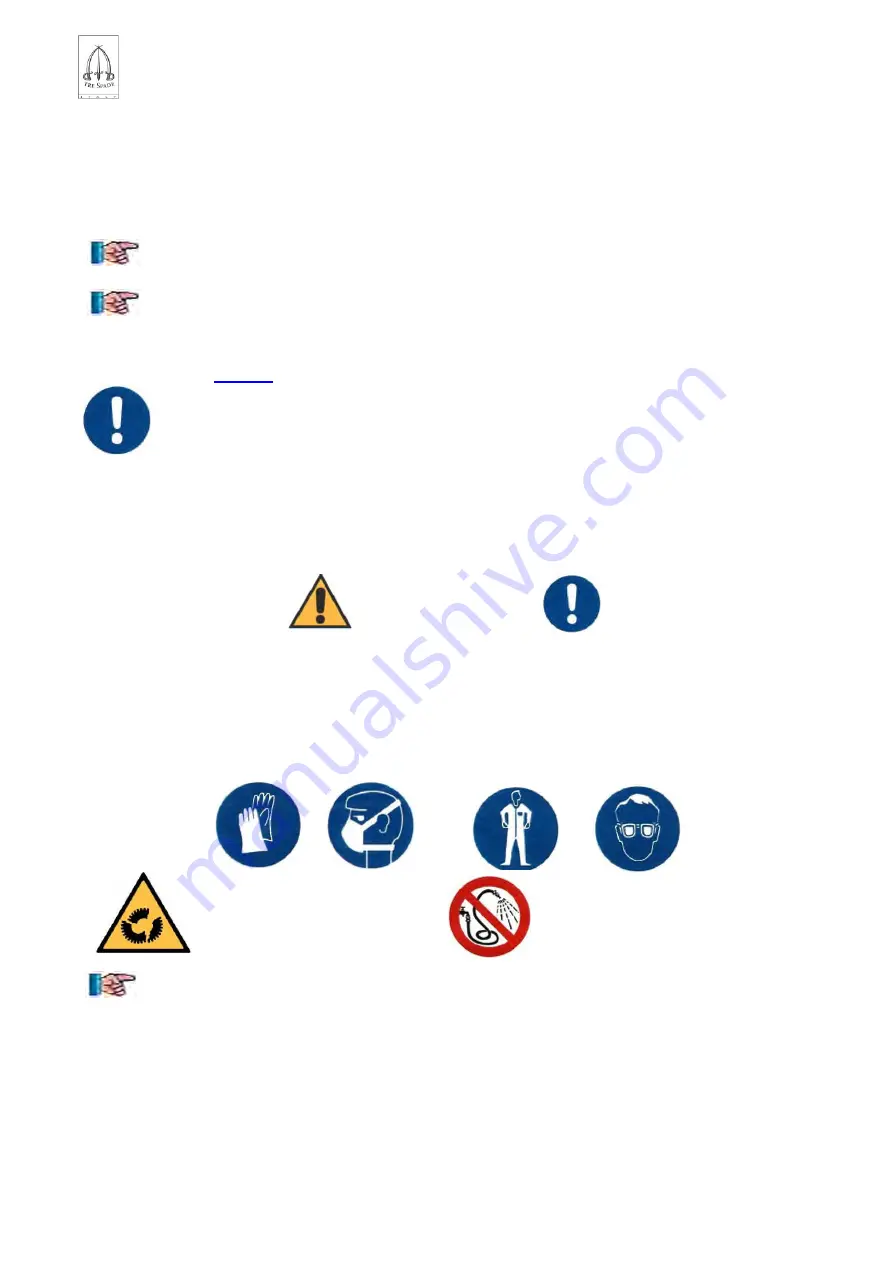

ATTENTION

The removal of the remainder from cuts in the work area or other parts of the machine

must be carried out using methods and tools appropriate for the purpose. Compressed air

may be used (only consisting of dry air).

When using compressed air, the operator must be sure of the absence of persons in its

range; the operator should wear a mask to protect the respiratory tract, a pair of safety

goggles, suitable gloves and suitable clothing.

DANGER THE

POSSIBILITY OF

DAMAGE TO THE

MACHINE EXISTS

DO NOT USE JETS OF WATER

TO CLEAN, GIVEN THE

PRESENCE OF

ELECTRIC PARTS

NOTE FOR BUSINESS USES - It should be remembered that when substances

are used by workers, the instructions given in the relative safety data sheets

of substances must be implemented, sheets that must be supplied by the

manufacturer and always be available in the company. The assessment must

be carried out in accordance with Legislative Decree 81/2008 Title IX

hazardous substances, Chapter I protection against Chemical Agents. For

other countries refer to the legislation in force.