8

Pre-Installation

Fusion

minipool

EN

80°C

176°F

The minipool works efficiently and safely if it is installed

correctly and in compliance with the regulations in force

in the country of use.

This pre-installation guide provides information for a

proper preparation of the environments and the plumbing

and electrical connections.

This allows for a quick and safe installation.

The pre-installation stages involve the following

professionals:

• A construction engineer for the calculation of the

loading capacity of the platforms or floors.

• A qualified and certified company that will prepare the

installation site according to the instructions provided

in this guide, following current work safety regulations.

• Certified and qualified electrician and plumber who

prepare electrical and plumbing systems in compliance

with local and national regulations regarding civil and

industrial systems.

The user must promptly notify the professionals of any

existing underground obstacles like gas or water lines

and electrical or telephone cables.

Upon completion of pre-installation all these specialists

must issue a declaration of conformity of the systems

installed. Without such document, the Manufacturer

declines any responsibility for damage to the systems or

premises where the minipool will be installed.

We recommend checking with the appropriate

municipal offices to see if there are constraints

that prevent installation or if permits are required.

An incorrect pre-installation could cause structural

damage to the minipool and void the warranty.

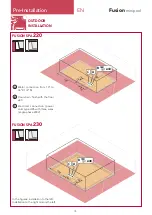

TEMPORARY POSITIONING

The installation of the minipool should be done

immediately upon receipt.

In any case, once unpacked, if it is necessary to

temporarily place it on a surface awaiting the installation,

it will be necessary to place level concrete slabs having

a minimum thickness of 5 cm under the entire bottom

of the minipool.

Since the temporary base may shift, it is recommended

to leave the minipool in that position for the shortest

possible time.

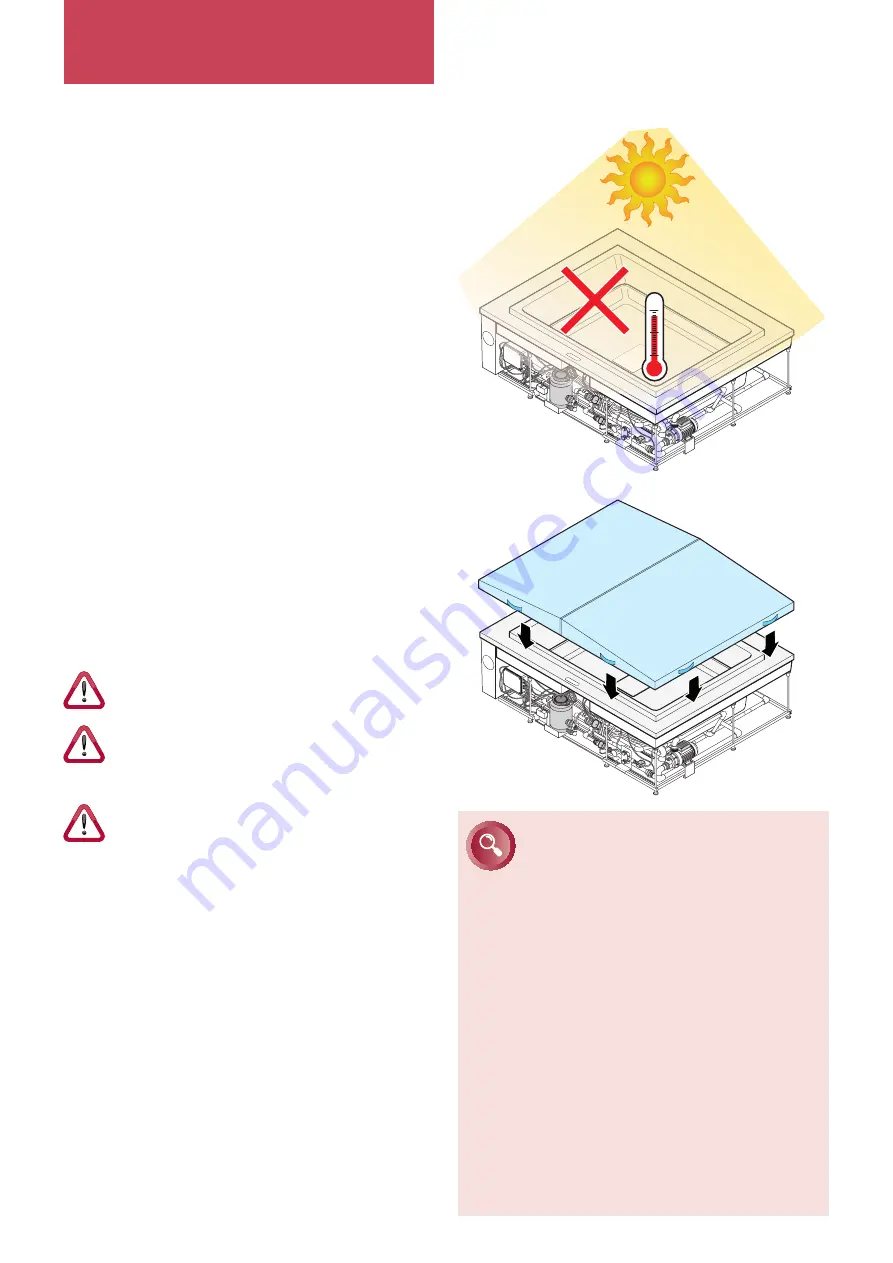

Do not leave the empty minipool in DIRECT SUNLIGHT.

The surface temperature could rise above 80°C resulting

in serious damage, including cavitation and the

deformation of the surface and components. Damage

caused by direct exposure to sunlight is not covered by

the warranty.

In such conditions place a cover (fixed or mobile) to

protect the minipool.

Please note

The Manufacturer cannot be held responsible and

does not recognise the warranty

in the case of:

• Installations or connections that are not

compliant

or that are carried out without following

the national regulations concerning civil and

industrial installations.

• Pre-installation and installation carried out

by unqualified personnel

or otherwise

not

in compliance

with the instructions in the pre-

installation and installation manuals.

• Incorrect preparation of the installation

environments

, including the supporting surface.

• Accidents

and damage

due to a non-compliant

installation or use of the bathtub.

• Masonry works

that prevent the removal and

handling of the minipool or defective parts thereof.