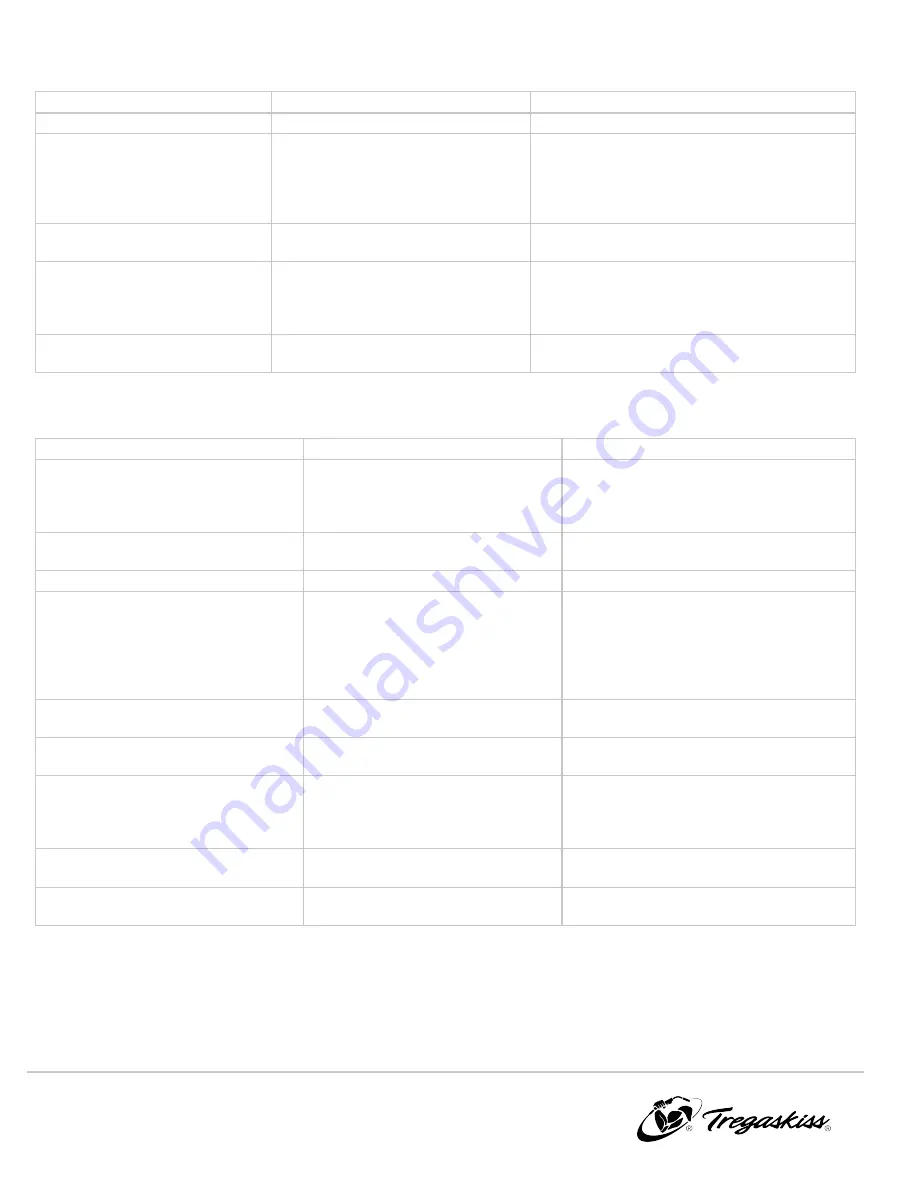

9-2 Lubricator

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Oil fill level low.

1. Oil depleted in bowl.

1. Refill oil bowl to correct level using air motor oil.

2. Incorrect oil drip rate.

1. Drip rate valve not set properly.

2. Filter element clogged.

3. Steel supply lines clogged.

1. Set drip rate valve so that one (1) drop of oil

occurs every 5-10 ream cycles.

2. Remove bowl assembly and clean filter element.

3. Remove steel supply lines and clean using

compressed air. If damaged, replace steel lines.

3. Air leaks between the bowl and

the body.

1. Breakage of bowl o-ring.

1. Replace bowl o-ring. Grease up before

assembling.

4. Air leaks from the drainage cock.

1. Foreign matter caught in the threads

of the drain cock.

2. Breakage of the seating part of the

drain cock.

1. Remove the drain cock and clean threads.

2. Replace the bowl assembly.

5. Too much drain comes from the

piping of the outlet side.

1. Drain level reaches the baffle plate.

1. Open the drain cock for draining and replace the

element.

9-3 Filter/Regulator

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Pressure is not regulated.

1. Opposite flow direction or opposite

installation of filter/regulator.

2. Foreign materials caught in the valve

seat.

1. Install piping or filter/regulator correctly as

shown in manual.

2. Remove the valve guide to clean the valve

and valve seat.

2. Set pressure does not return to zero

when pressure handle is loosened.

1. Foreign materials caught in the valve

seat.

1. Remove the valve guide to clean the valve

and valve seat.

3. Large air resistance reduces flow rate.

1. Clog of the element.

1. Clean the element.

4. Air leaks from the bonnet exhaust port. 1. Diaphragm is damaged.

2. Foreign materials caught in the valve

seat.

3. Piston o-ring is damaged.

1. Replace the assembly.

2. Remove the valve guide to clean the valve

and valve seat.

3. Replace the piston o-ring or clean. Then

grease up the piston o-ring and sliding

surface.

5. Air leaks between the bonnet and the

body.

1. Loosened bonnet.

2. Diaphragm is damaged.

1. Fasten the bonnet.

2. Replace the assembly.

6. Air leaks between the bowl and the

body.

1. Breakage of bowl o-ring.

1. Replace bowl o-ring. Grease up before

assembling.

7. Air leaks from the drainage cock.

1. Foreign matter caught in the valve of

the drain cock.

2. Breakage of the seating part of the

drain cock.

1. Open the drain cock for a few seconds.

2. Replace the bowl assembly.

8. No drainage when the drain cock is

open.

1. Blockage of outlet of the drain cock

due to solid foreign matter.

1. Replace the bowl assembly.

9. Too much drain comes from the piping

of the outlet side.

1. Drain level reaches the baffle plate.

1. Open the drain cock for draining and

replace the element.

35

OM-TT3-1.4