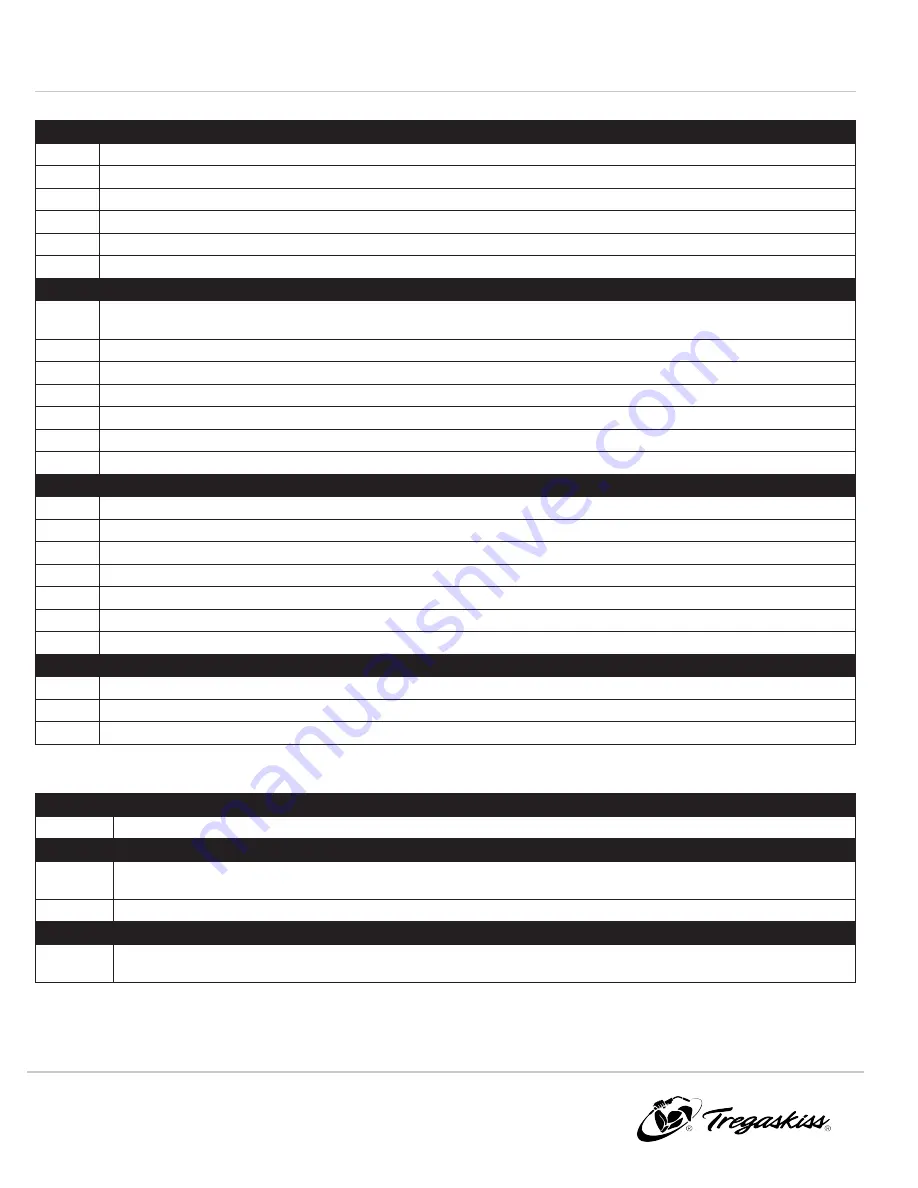

6-8 Scheduled Maintenance

The

TOUGH GUN TT3 Reamer

will require a periodic maintenance program to ensure a reliable service life, as recommended below:

DAILY

CHECK

The oil level in the lubricator reservoir.

The life of the air motor is dependent on a consistent supply of oil.

CHECK

The air lines and interface cable for leaks and fraying.

CHECK

The alignment of the nozzle, retaining head/diffuser and gun position.

CHECK

The reservoir to ensure it is full of TOUGH GARD® Anti-Spatter Liquid.

CLEAN

The spindle cover shroud to ensure it is free of spatter.

CLEAN

The reamer clamp jaw and v-block surfaces to ensure proper nozzle alignment.

WEEKLY

CHECK

The nozzle cutter blade.

The service life of the cutter blade is dependent on the type of application. In lighter duties, the blade

may last indefinitely but should be inspected weekly for dullness, clogging and possible breakage.

CHECK

The lubricator to ensure it is working and is set up properly (i.e. fill oil, clean / replace filter).

CHECK

The LEDs to ensure reamer and controller communication.

CHECK

The sprayer to ensure that the spray coming out of the spray head is normal.

CHECK

The nozzle and retaining head/diffuser (remove from gun) for wear.

CLEAN

The v-block, reamer clamp jaw, and spindle seal with a brush or with compressed air to eliminate blockages.

CLEAN

Wipe clean any debris from the Nozzle Detect Proximity Sensor.

MONTHLY

CHECK

That the belt tension lock screw is securely tightened.

CHECK

That the belt tension bolt is tightened.

CHECK

The spindle unit for wear.

CHECK

The solenoids and spool them to ensure there are no leaks and that they are operating properly.

CLEAN

The sprayer reservoir to eliminate contamination.

CLEAN

The sprayer head and brush away excess spatter.

CLEAN

Under the top cover.

YEARLY

INSPECT

The drive belt for any signs of fraying and replace as necessary.

REPLACE

The spindle cap seal and repair any damage to the spindle.

CLEAN

Perform a complete clean-up of the reamer and sprayer.

The

TOUGH GUN Wire Cutter

will require a periodic maintenance program to ensure a reliable service life as recommended below:

DAILY

CHECK

The air lines and interface cable for leaks and fraying.

WEEKLY

CHECK

Check the wire cutter blades for dullness, looseness and possible breakage.

The service life of the cutter blades is

dependent on the type of application. In lighter duties, the blades may last indefinitely but should be inspected weekly.

EMPTY

The wire catcher basket.

QUARTERLY

LUBRICATE

The sliding surfaces by applying general purpose grease (NLGI Grade 1-2) through the grease fittings located on the sides

of the main body.

28

OM-TT3-1.4