6-2 Installing the Wire Cutter

WARNING:

Ensure air and power supply is off and disconnected before

proceeding. Please follow your facility's lockout / tagout procedures.

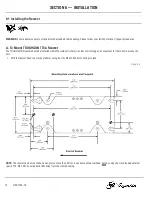

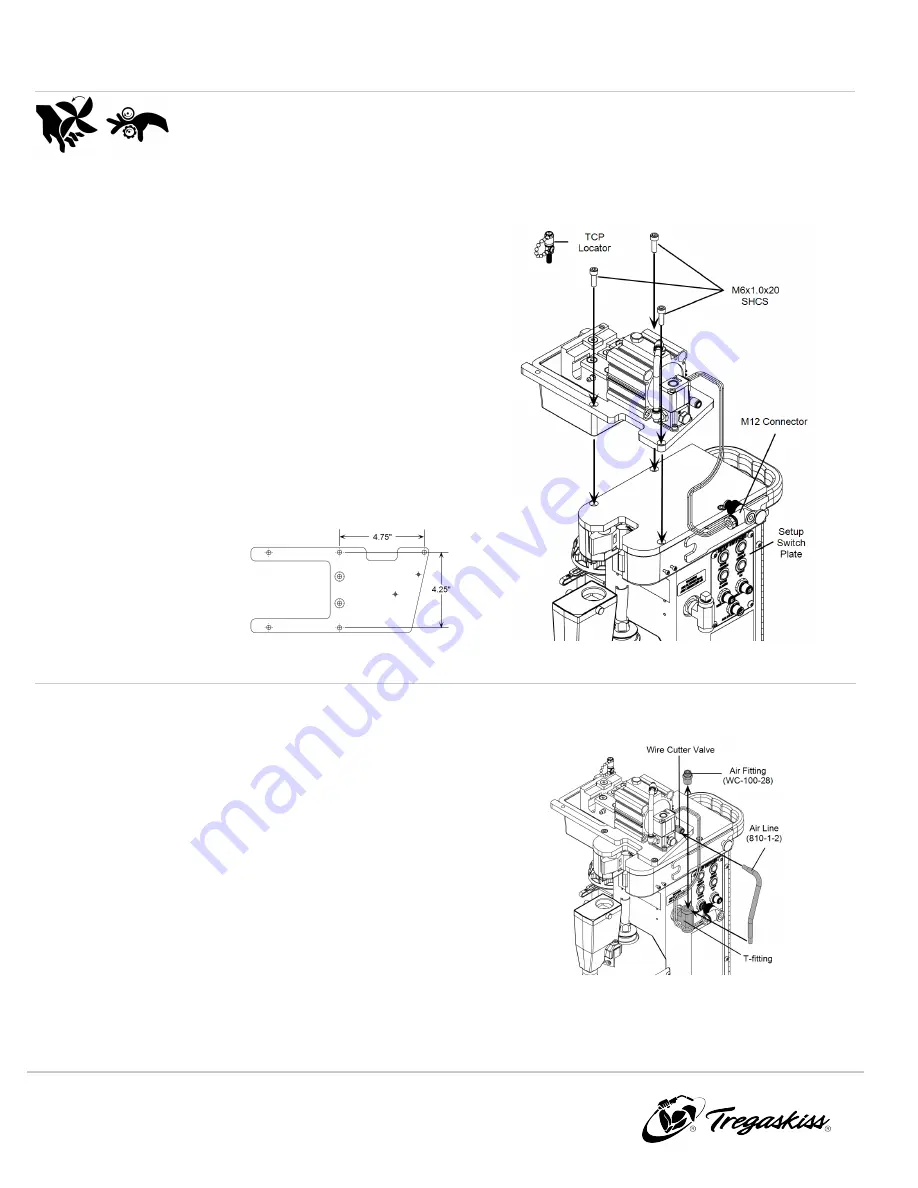

A. Mounting Wire Cutter

1. The wire cutter should be installed within the weld cell where it is

clear of all tooling and convenient for the robot to access the unit.

The base plate has been designed for mounting on top of the

TOUGH GUN Reamer. Be sure to consider movable fixtures and the

confines of the robot.

2. Attach the WC-400 wire cutter base to the top of the reamer, or

other sturdy platform using the same three (3) M6x1.0x20 mm

Socket Head Cap Screws (SHCS) that are securing the clamp

housing cover onto the reamer. (see Figure 6-D)

3. If mounting a WC-100 wire cutter (old style) to the reamer, use

three (3) M6x1.0x25 mm SHCS.

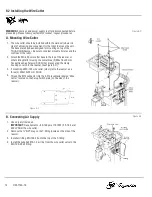

4. Thread the M12 connector into the 4-Pin receptacle labeled “Wire

Cutter” located on the Setup Switch plate (on the side of the

reamer).

Figure 6-C

Figure 6-D

B. Connecting Air Supply

1. Use only dry filtered air.

IMPORTANT:

Requirements – 80-100 psi at 16 CFM (5.5-7.0 bar at

450 LPM) at the wire cutter.

2. Remove the ¼” NPT plug on the T-fitting located on the side of the

reamer.

3. Install air fitting WC-100-28 onto the top of the T-fitting.

4. Install the supplied 810-1-2 air line from the wire cutter valve to the

WC-100-28 air fitting.

Figure 6-E

14

OM-TT4A-1.0