7-7 Setting Up Nozzle Detect

WARNING:

Please follow your facility's lockout / tagout procedures.

IMPORTANT:

In order for the system to operate properly, the sensor signal must be monitored.

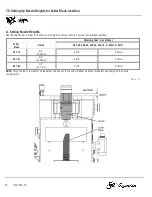

A. Setting Up Nozzle Detect

1. With a nozzle on the gun, move the robot into position beside the nozzle detect sensor.

2. Measure the distance from the tangent face of the nozzle to the face of the nozzle detect sensor, ensuring that it is 3 mm ± 1 mm.

3. The ring crimp on the nozzle should be in line with the center of the sensor (yellow circle portion on the face of the sensor). The

vertical distance between the top of the reamer clamp housing and the base of the nozzle outer shell should be approx. 0.10".

Figure 7-E

OM-TT4A-1.0

21