8-2 Programming Events Sequence

A. Programming Cutter Blade / Reamer Sequence

1. Verify the TOUGH GUN Reamer L.E.D. is showing

Unclamped

and

Reamer Home

.

2. Position the robot to place the MIG gun nozzle so it is tangent to the two (2) angled faces of the v-block, at the proper insertion depth

and concentric with the cutter blade (see section 7-6 Setting Up Nozzle Heights for Cutter Blade Insertion on page 20).

3. Cycle Start - Supply output signal from the robot controller / PLC. Pulse output for 0.5 seconds.

4. TOUGH GUN Reamer will perform cleaning cycle.

5. When the Cycle Start signal is supplied to the reamer,

Reamer Home

and

Unclamped

L.E.D.s will turn off. There should be no

illuminated L.E.D.s on the board until the reamer reaches the top of its stroke. At this point, the

Reamer Ahead

L.E.D. will illuminate

for a split second before the spindle begins to retract.

6. Once the reamer reaches the bottom of the stroke again, the motor will stop spinning, the clamps will open to release the nozzle and

the

Reamer Home

and

Unclamped

L.E.D.s will be illuminated again. The PLC should check for the Home signal before letting the

robot move.

7. The gun can now be safely removed from the TOUGH GUN Reamer clamps and moved to its spray position.

B. Programming Sprayer Sequence

Important Note:

Do not

use oil-based anti-spatter solution, as

this will compromise performance.

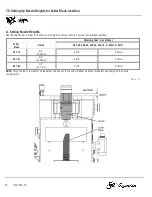

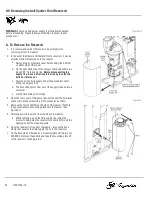

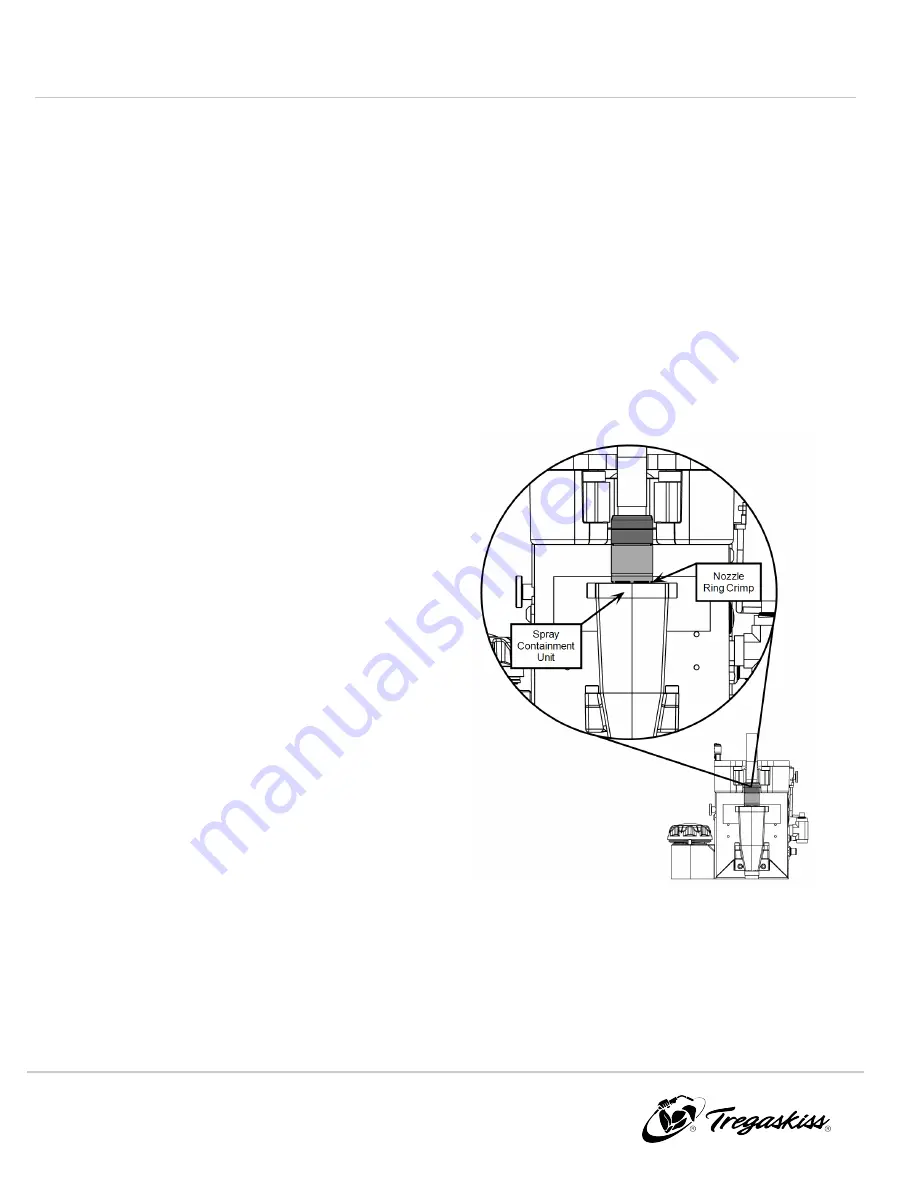

1. After reaming, center the nozzle above the hole on the

cover of the spray containment unit.

2. Insert the gun directly into the spray containment unit until

the crimp ring of the nozzle is flush with the top of the

spray containment cover. (see Figure 8-B)

3. Supply output signal from robot controller for 0.5 seconds

for initial setup. Adjust timer to increase or decrease

quantity of anti-spatter compound as required by process.

4. Retract the gun from the spray containment unit once the

spray is complete.

IMPORTANT:

If MIG gun is equipped with air blast, DO NOT

activate air blast when over the spray head. Dirt / spatter may

be blown into the spray head orifice, which may hamper spray

operation. Air blast can be activated during the reaming

sequence.

Figure 8-B

24

OM-TT4A-1.0