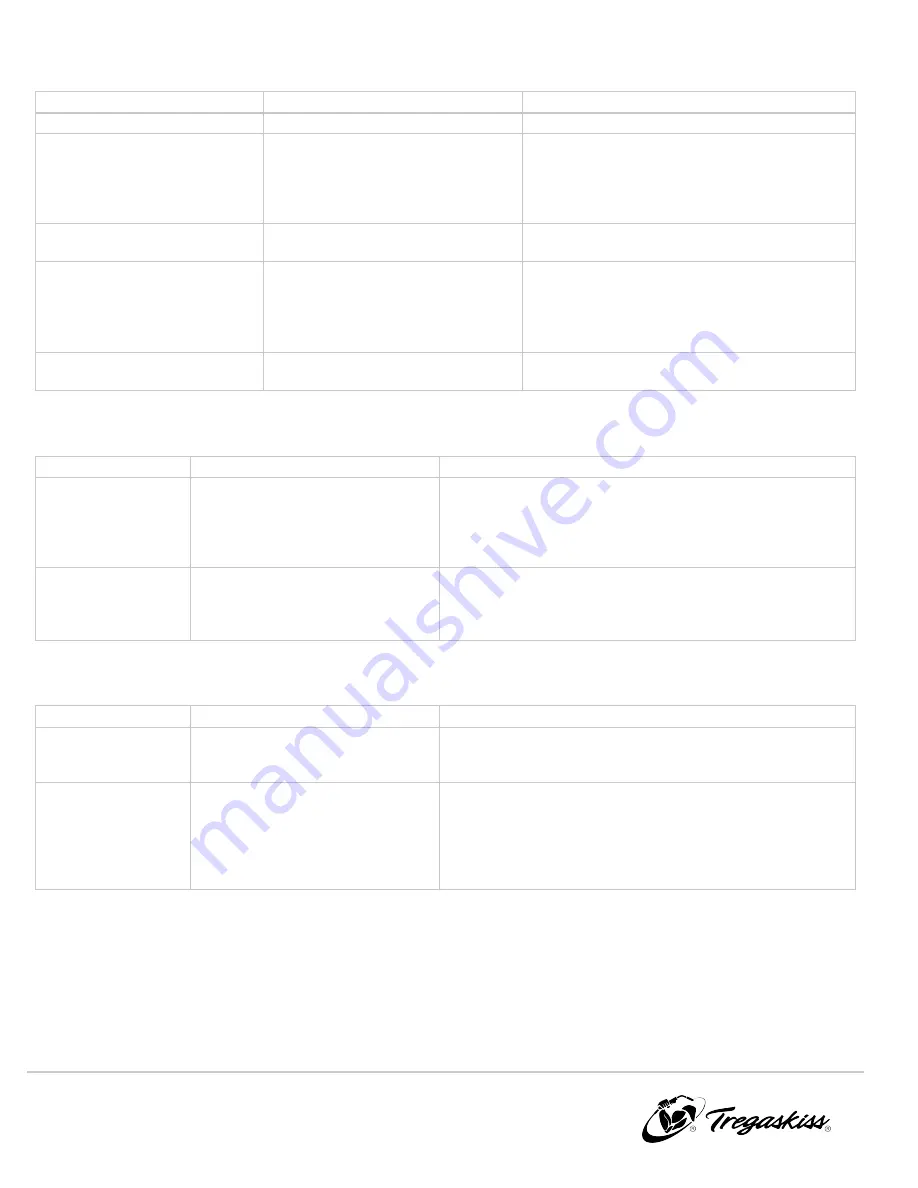

12-2 Lubricator

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Oil fill level low.

1. Oil depleted in bowl.

1. Refill oil bowl to correct level using air motor oil.

2. Incorrect oil drip rate.

1. Drip rate valve not set properly.

2. Filter element clogged.

3. Steel supply lines clogged.

1. Set drip rate valve so that one (1) drop of oil

occurs every 5-10 ream cycles.

2. Remove bowl assembly and clean filter element.

3. Remove steel supply lines and clean using

compressed air. If damaged, replace steel lines.

3. Air leaks between the bowl and

the body.

1. Breakage of bowl o-ring.

1. Replace bowl o-ring. Grease up before

assembling.

4. Air leaks from the pressure

relief/drain valve.

1. Foreign matter caught in the valve.

2. Breakage of the sealing parts of the

valve.

1. Remove the bowl and clean the inside of the bowl.

Flush the valve with a solvent to remove the debris.

2. Replace the bowl assembly.

5. Too much drain comes from the

piping of the outlet side.

1. Drain level reaches the baffle plate.

1. Open the drain cock for draining and replace the

element.

12-3 Spray Containment Unit

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Over spray is

excessive.

1. Misalignment of gun.

2. Gun not inserted into the spray

containment unit far enough.

3. Baffle not installed.

1. Position the gun to be in the center of the opening on the spray

containment unit.

2. Insert gun to the depth specified in 8-2 Programming Events

3. Ensure that the internal baffle is installed properly.

2. Fluid and debris are

not draining out of

the unit.

1. Plugged drain hose.

2. Plugged container/drain hole.

1. Remove drain hose from the spray containment unit and clear

blockage.

2. Remove top cover of the spray containment unit and clean out

any debris that is blocking the drain hole.

12-4 Anti-Spatter Fluid Reservoir

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Fluid is leaking from

the reservoir.

1. Damaged reservoir.

2. Hose clamp not installed on the

outlet tube.

1. Replace reservoir.

2. Replace hose clamp.

2. Low fluid level

signal not present.

1. Wire connections are loose.

2. Faulty sensor.

3. Float stuck in the upward position.

4. Damaged sensor.

1. Check the 2-pin connector on the inside of the reamer, ensure

that it is fully connected to it's mating connector.

2. Replace sensor.

3. Open the cap of the reservoir and gently press the float

downward. If it does not move, replace the sensor.

4. Replace sensor.

40

OM-TT4A-1.0