TECHNICAL SPECIFICATIONS

Description

7” Air

Weight

2.9kg/6.38lbs

Spindle dia

5/8” UNC

Power requirements

12cfm@90psi (3/8””BSP inlet)

Maximum air pressure

7 bar (100psi)

No load RPM

7,000 RPM

Recommended hose bore - to a max length 10 metres

10mm (3/8”)

Vibration (AEQ)

Primary hand position (trigger position)

6.2m/s

2

(k)

Test method in accordance with ISO standards BS EN ISO 28927-12:2012

Noise

Noise LpA (Pressure Level)

90.0dB(A)

Test methods in accordance with Pneurop test code PN8NTC1 & ISO 3744

MAINTENANCE

For the motor make sure that the end

plates that abut the cylinder are free from

burrs and sharp edges and if necessary

lap on a flat fine grade of abrasive paper.

Press bearing (15) into rear case (26) and

support the inner race of bearing (15) and

press the non splined end of rotor (24)

into the assembly.

Tap the rotor relative to the rear case and

bearing assembly until a clearance of

approx. 0.0025” (0.065mm) is achieved

between the rotor and the rear case.

Ensure the rotor spins freely before

assembling the rest of the motor

assembly.

Reassembly

Clean all parts and examine for wear.

Use only distributor or manufacturer

supplied spare parts.

Particularly examine O-rings, bearings

and gears.

Coat all parts in a pneumatic tool

lubricating oil, one preferably containing a

rust inhibitor.

Grease bearings and gears with a

molybdenum or lithium based general

purpose grease.

Reassemble in the reverse order.

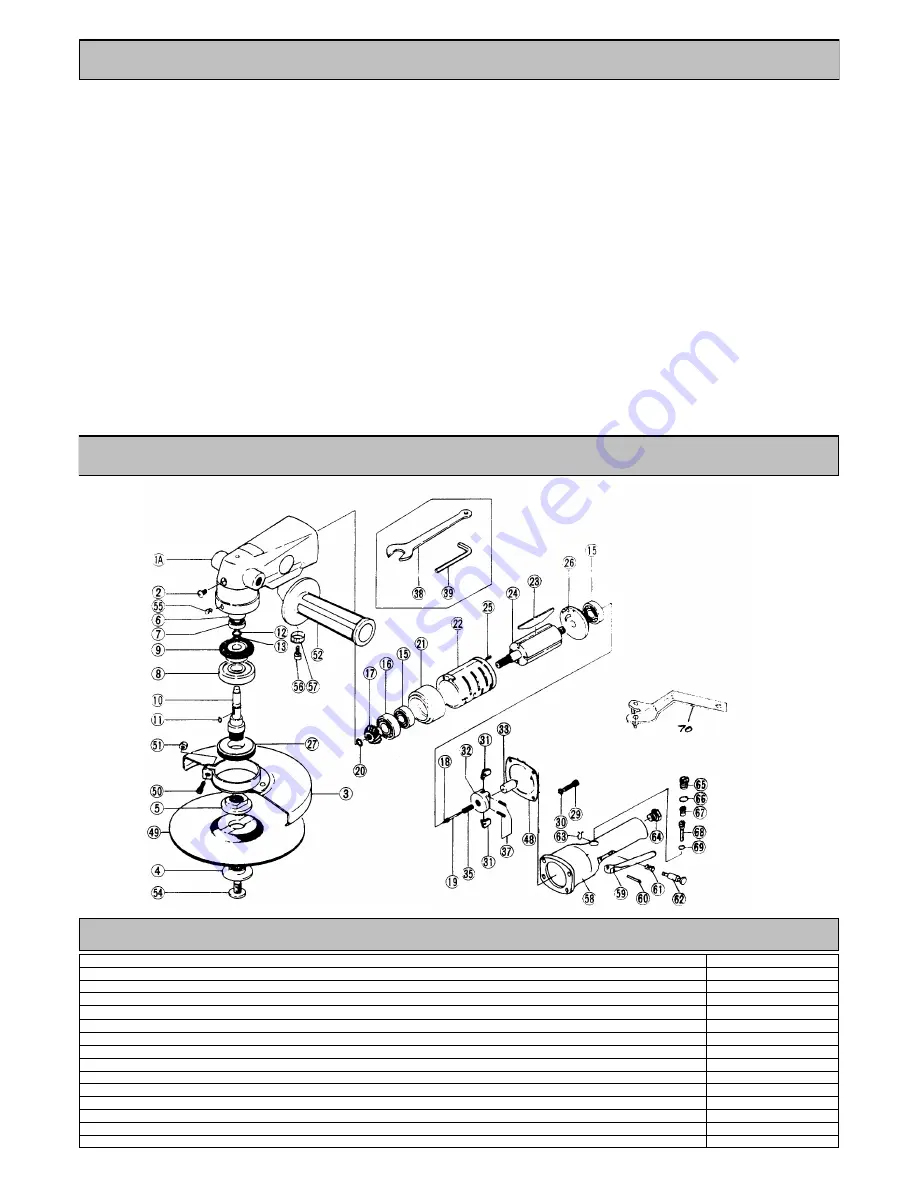

This machine has a speed controller or

governor, parts (21), (28), (42), (44), (45)

and (46).

The correct setting of this speed controller

is critical to the safety of the tool and

should only be carried out by a trained

competent person.

The speed is set by assembling the speed

controller, measuring the output spindle

gear shaft (11) speed with a calibrated

tachometer.

Adjustment to the spindle speed can be

made by rotating adjust screw (42).

The speed of the grinder running free with

an air inlet pressure of 100 psi (7 bar)

measured at air inlet (57) must not

exceed 7,000 RPM.

EXPLODED VIEW