SERVICING continued

It is permissible to operate the machine with a

backward and forwards action, each pass should be

overlapped to produce a uniform finish.

7. In emergency, when the cutter drum must be

lifted quickly from the work surface, it is not

necessary to turn the hand wheel, simply pull

backwards and downwards on the handlebar to lift

the front wheels and Cutter Drum off the floor, and

then release the Deadmans handle.

Shut Down

1. Turn the Hand Wheel clockwise to its full height,

until the machine‟s wheels are locked and act as a

brake.

Air Motors versions

, turn the tap on the lubricator

anti-clockwise until at right angles to the lubricator.

Electric versions

, release the Deadmans handle,

and disconnect from the supply.

2.

Petrol versions

, still holding the Deadmans

handle, move the engine‟s throttle lever to the slow

speed position and run the engine for 10 seconds.

(This avoids the engine from becoming washed

internally by neat fuel if switched off from high

engine revolutions.)

3. Release the Deadmans handle or switch off main

engine switch the engine will then stop.

4. Switch off the main engine switch.

5. Close the engine fuel cock.

:EMERGENCY SHUTDOWN:

Petrol and Electric Models: Release Deadmans

handle.

Air Motor: Turn off lubricator stop tap.

The clevis pin should be lubricated regularly with oil

to maintain a light, smooth height adjustment.

The toothed Drive Belt will give a long and trouble

free life if basic procedures are followed.

Daily check the drive pulleys for build up of deposits

and any trapped debris etc.

Check the belt and teeth for surface cuts and cracks,

as once the surface of the belt is damaged it will

soon fail.

Build up of dirt can cause two problems:

The belt can become over tightened through the

build up of dirt underneath the teeth and therefore

may no longer mesh correctly, all of the power is

then transmitted by the tip of the teeth with obvious

negative results.

Serious damage could result to the drive shaft,

bearings and drive motor if the belt is excessively

tight.

Generally when the motor is started and run a tight

belt can be detected by a low hum or whistle.

Warning

: Never operate the TFP200 without a belt

guard.

All fastenings should be checked daily for tightness

and the drive belt for tension.

Check the individual motor or engine manufactures

instructions for details on their service

recommendations.

Short period storage: up to 3months.

Clean outside of machine, inspect the Drum, flail

shafts and cutters for wear; replace any worn parts

as required.

Remove any build up of material from inside of the

Cutter Drum area.

Cover the machine to protect it: Store the machine in

a dry place.

Be sure to check security of all fastenings after any

lay up period.

See also engine manufactures operation and

maintenance instruction book.

Long period storage: over 3months

Clean outside of machine, inspect the Drum, flail

shafts and cutters for wear; replace any worn parts

as required.

Remove any build up of material from inside of

Cutter Drum area.

When engine is cold, remove the fuel from the fuel

tank and carburettor float chamber; see engine

manufactures operation and maintenance instruction

book for method.

Cover the machine to protect it: Store the machine in

a dry place.

After any long lay up period be sure to check

security of all fastenings, change engine oil as per

engine manufactures instructions and refill the tank

with fresh petrol.

See also engine manufactures operation and

maintenance instruction book.

Note: Always follow local regulations on the storage

of petrol and for the disposal of used engine oil.

IMPORTANT

Normal slack should be approximately 10~15mm

(1/2") when the belt is depressed on one side in

the middle position between the engine pulley

and drive pulley.

FAULT

CAUSE

ACTION

Engine stops suddenly or does not

run correctly

No fuel in the fuel tank.

Refuel fuel tank. (See safety section.)

Spark plug faulty.

Replace spark plug.

Fuel blockage.

Check fuel line and strainer.

Air cleaner blocked.

Replace air cleaner element.

Low oil level. (A low oil cut out is fitted)

Rectify leaks and replenish oil.

Electric motor stops suddenly

Blown electrical supply fuse.

Replace fuse.

Motor overload protection activated

Disconnect electricity supply at mains and reset button inside starter box.

Electric motor will not start

Deadmans handle not engaged

Pull Deadmans lever against handle bar and press start button.

Planer is slow or erratic

Drive Belt slack or failed.

Replace Belts or adjust tension.

Worn Drum Cutters

Replace Cutters.

Loose or a failed drive belt.

Replace Belts and adjust tension.

Surface too rough.

Use Trelawny TF260 surface Planer to increase production.

Low air supply or air pressure

Requires a minimum of 160cfm @ 90psi

Engine will not start

No fuel in the fuel tank.

Refuel fuel tank, see safety precautions.

Low oil level.

Rectify leaks, replenish oil.

Water in fuel/wrong fuel type

Drain fuel tank, float chamber, and refuel with correct fuel type.

Spark plug faulty.

Replace spark plug.

Engine will not turn over

Oil in Cylinder.

See section.

1 - Safety Precautions

.

Use above information in conjunction with the engine manufacturers Operation and Maintenance Manual.

If problem has not been cured by above actions, contact your local Trelawny agent or engine manufacturer for advice or rectification.

4. Slide the toothed belt off the engine pulley and

then remove the belt from the drive pulley. It may be

necessary to lift the left hand end (viewed from the

front of machine) of the engine/motor slightly to

facilitate removal and also during installation.

5. Place the new belt partially onto the drive pulley

first; locate the belt‟s teeth in the drive pulley‟s tooth

grooves.

6. Then slide the belt over the engine drive pulley,

slide the belt fully into position, and ensure that both

pulleys have the belt‟s teeth engaged in the grooves

and that the engine/motor pulley is positioned

directly above the drive pulley.

7. Adjust the tension of the belt by moving the

engine towards the front of the machine.

When the engine is in the correct position, (Normal

slack should be approximately 13mm (1/2")) lightly

tighten the engine retaining bolts and recheck the

belt tension.

The engine must also be parallel to the front of the

engine mounting plate otherwise the belt will not run

true.

Please bear in mind that the belt will also tighten

further as the engine mounting bolts are tightened.

Adjust the engine position until the correct belt

tension is achieved. Carefully rotate the drive pulley

by hand to ensure that the belt is running true.

8. Finally tighten all engine bolts, refit the belt guard

and tighten the belt guard-retaining

bolt.

Belt Installation &

Adjustment

1.

Ensure that all power or air to the machine is

switched off and disconnected.

2. Remove the belt guard by unscrewing the bolt in

the centre of the belt Guard.

3. Loosen the engine mounting plate bolts to allow

the engine to move along the chassis‟s engine

mounting bolt slots and on electric motors loosen

also the motor to slide mounting fixing bolts.

Maintenance & Machine

Storage

After use, clean the machine to remove all build up

of dust and surface residues. If using a hosepipe or

pressure washer take care not to direct water at

electrical components and switches.

Note: Motors and switches are not waterproof.

Ensure that the height adjustment thread is cleaned

and then lightly greased. Periodically it should be

completely removed and the female thread section

cleaned and greased. At the same time the self-

aligning bearing at the top of the shaft should be

greased using a grease gun.

Summary of Contents for TFP200

Page 1: ...TFP200 FLOOR PLANER OPERATION MAINTENANCE ...

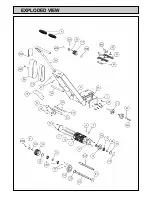

Page 6: ...EXPLODED VIEW ...

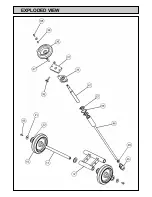

Page 7: ...EXPLODED VIEW ...