BS/JIG

-11-

-11-

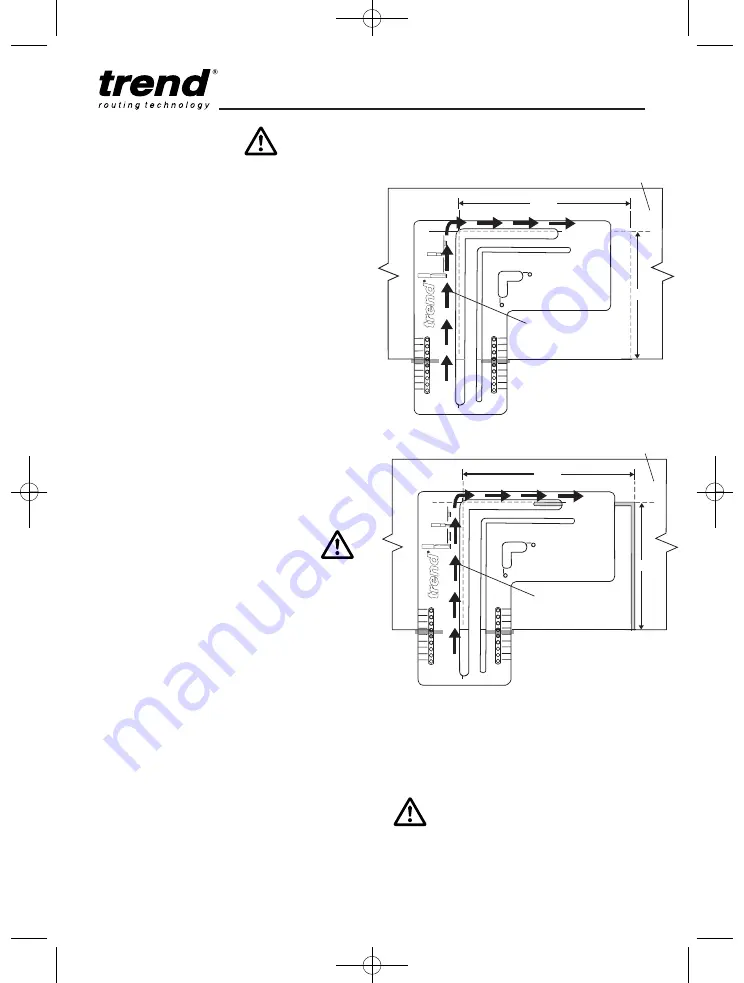

Routing the Worktop

I

With a 30mm guide bush and a 12.7mm

cutter fitted to the router, set the depth of cut

at approximately 8mm. Position the router in

the sink recess slot, switch on the router,

plunge down and rout the left half of the

recess. Cut in from the worktop edge,

travelling in a clockwise direction.

I

Increase the depth of cut and repeat until cut

is complete. At the end of each cut release

plunge and switch off router.

I

Remove the jig and then carefully turn the

worktop upside down.

I

To rout the second half of the recess, re-

position the jig as shown. Remember to re-

insert any packing piece that was used for

routing the first half. The sliding datum block

may be needed to line up.

I

Clamp the jig in place. Remove the sliding

datum block if used. Rout the remaining side,

again ensuring that the worktop is supported,

including the waste piece.

340

360

380

400

420

440

460

480

500

340

360

380

400

420

440

460

480

500

90°

517mm

Topside of worktop

r

outing

technology

30 mm

16 mm

12.7

mm

BS/JIG

For

Recess

For

W

ater

Drip Groove

R2.5 mm

405mm

Direction of

router travel

340

360

380

400

420

440

460

480

500

340

360

380

400

420

440

460

480

500

90°

517mm

Underside of worktop

r

outing

technology

30 mm

16 mm

12.7

mm

BS/JIG

For

Recess

For

W

ater

Drip Groove

R2.5 mm

405mm

Direction of

router travel

Routing the Water Drip Channel

I

A water drip channel can be routed to the

underside of the worktop to allow water to

drain off.

I

Fit a 16mm guide bush and a R2.5mm radius

cutter to the router.

I

With the worktop surface faced downwards,

line the inner edge of the jig’s drip channel

groove with the recess edge and clamp in

place. This will give a drip channel about

5mm back from the recess.

I

Set the router cutter to plunge about 5mm

into the worktop. Ensure the 16mm guide

bush is placed in the drip channel slot. Start

the groove 5mm from the worktop front edge

and rout in a clockwise direction.

I

After the first half has been routed,

re-position the jig for the second half

and repeat the operation.

I

Stop the groove 5mm before the worktop

front edge.

1st Half

2nd Half

Ensure the drip groove starts 5mm in

from the worktop front.

MANU/BS v1 25/3/11 16:33 Page 11