VJS/AG/36

-9-

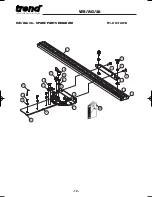

Clamping

Always use a minimum of two clamps to hold the

main body assembly of the angle guide to the

component and a third clamp to clamp extrusion.

The material being cut will need to

supported and clamped securely.

When carrying angle guide ensure

both protractor assembly and alloy

extrusion are held safely.

Clamp

Clamp

Component

Always place power tool to the right

hand side of the alloy extrusion, to

prevent the cutting tool cutting into

the main body assembly.

Routing or Sawing using the

Angle Guide

Before cutting ensure the router or saw will run

along the length of the alloy extrusion without

fouling. Always place the power tool to the right

hand side of the alloy extrusion.

I

Ensure power tool cable cord is kept clear of

cutting area, and that the cutting blade will not

damage anything below the component.

I

Always feed the power tool the correct way

along the alloy extrusion.

I

When using a saw, ensure the circular saw

motor body does not foul the assembly. Adjust

the saw plate to raise the motor higher if

necessary.

When using a portable circular saw,

which has a left sided motor body,

ensure the depth of cut is set so that

the motor body is a minimum 35mm

(1-3/8”) above the component.

Alternatively if practical use the saw

from the other end of the extrusion.

Regularly check knobs, handles and

locking nuts are tight.

I

If a housing is being routed which is wider

that the router cutter, the angle guide can be

repositioned for the second cut, by loosening

the clamps, moving to new position and then

clamping again.

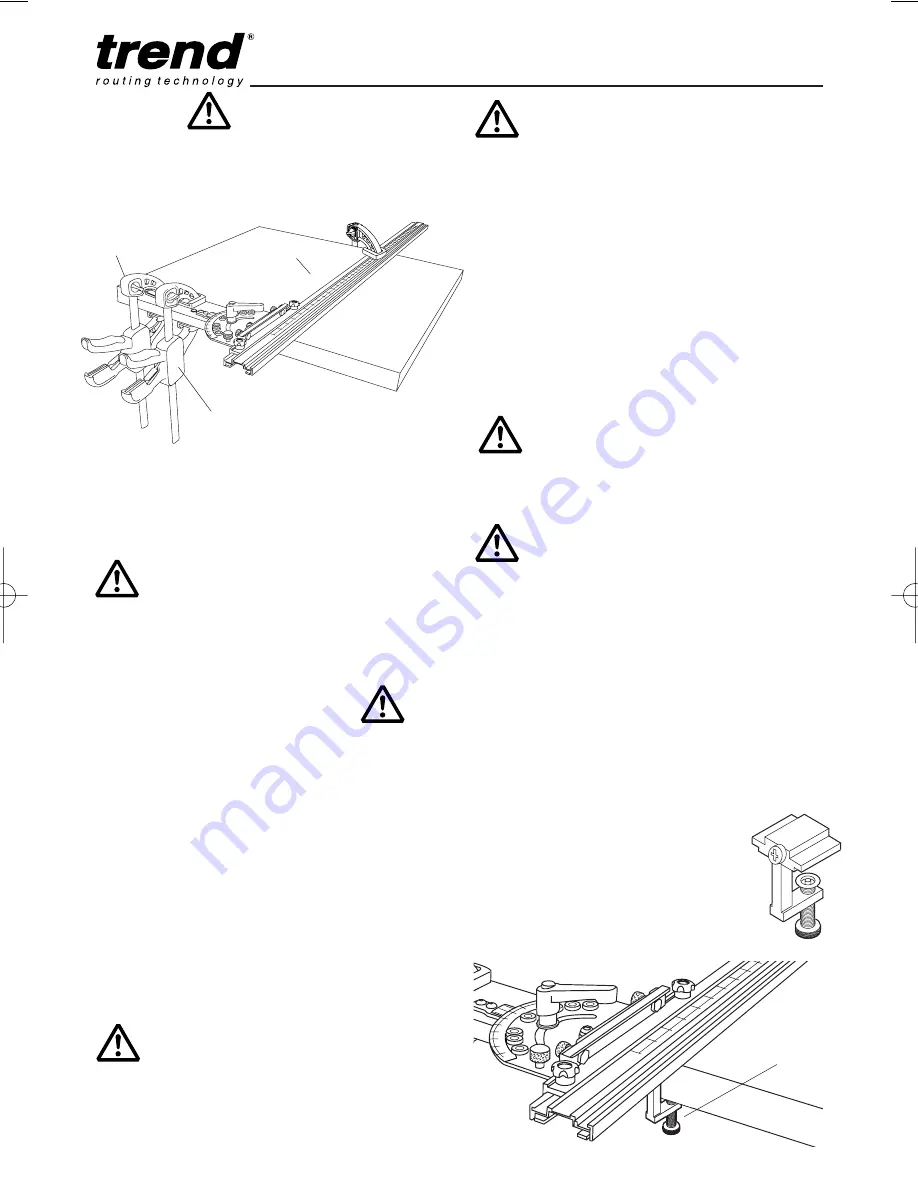

ACCESSORIES

Only use original Trend accessories:

Two types of friction clamp are available. They

can be used with the guide between 30º to 150º.

One clamp is fitted at either end of the extrusion.

Please note at shallow angles the clamp pad will

overhang the edge of the component.

Ref. VJS/CK

Sliding friction clamp (pair) clamping

thickness 32mm (1 1/4”)

Ref. VJS/CK/L

Sliding friction clamp (pair) clamping

thickness 51mm (2”)

VJS/CK/L Clamp

Alternatively a pair of accessory friction sliding

clamps can be used. Please see Accessories

Section. Once the end caps has been removed,

they are inserted into each end of the extrusion

and slid into the required positions.

MANU/VJS/AG/36 v1.0 3/2/10 12:57 Page 9