VJS/AG/36

-6-

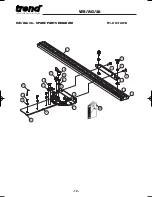

The angle guide requires assembly before use,

please use the drawing on page 5 as a guide.

I

Remove knurled locking knob and place in

park on the protractor.

I

Place plastic washer and metal washer on

stud on protractor assembly and fit adjustable

locking lever.

ASSEMBLY & ADJUSTMENT

Park

Metal Washer

Plastic Washer

I

Remove end caps on the extrusion and

slide the two T-nuts into the slot of the

extrusion.

I

Refit end caps to alloy extrusion.

I

Fit fixing screws into the alloy connector (the

hex head sits in the channel) and then the

metal washers. Loosely tighten female knobs

onto the screws.

I

Fit the alloy connector to the alloy extrusion

by locating the two holes of the alloy

connector with the two T-nuts in the alloy

extrusion. Place the plastic washers over

each hole and secure with the male knobs.

Adjusting Guide Angle

I

Loosen the locking lever and angle the

extrusion at the required angle.

I

Lock angle protractor by tightening the

locking lever.

I

The angle guide has a range from 25º to 155º.

90

80

70

80

70

50

60

40

30

0

5

5

60

50

40

30

155°

25°

I

Tighten the two male knobs.

I

Place alloy extrusion and connector assembly

on the protractor body washers and tighten

the male knobs to secure.

MANU/VJS/AG/36 v1.0 3/2/10 12:57 Page 6