TER-8/1200

4668

“EGA Spółka z o.o.” Spółka Komandytowa ul. Rzeczna 1, Nowa Wieś Rzeczna

83-200 Starogard

Gdański tel/fax:+48 58 56 300 80

29

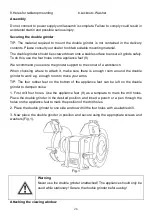

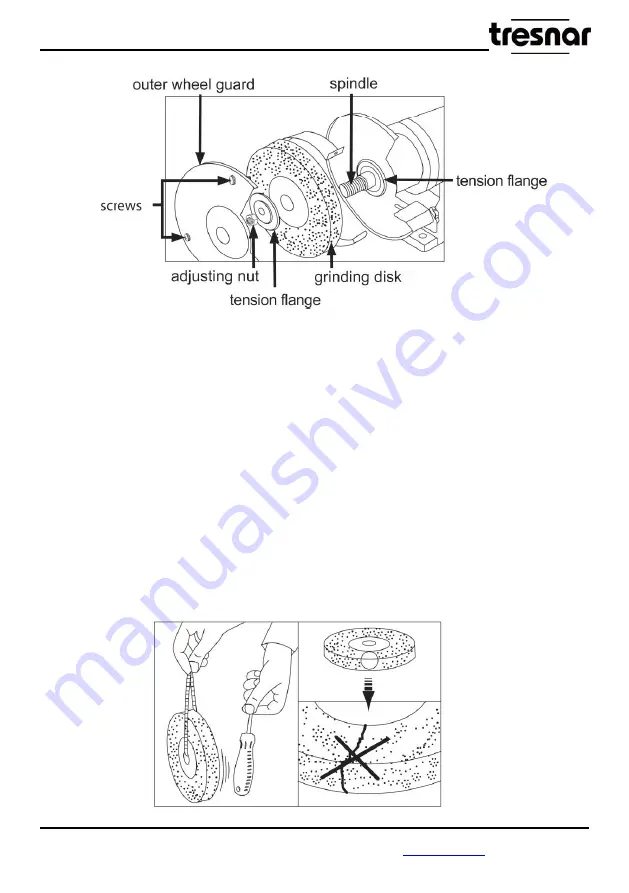

the tension flange (8).

Fig.4

TIP: Place the screws, washers, nuts etc. carefully to one side and within easy reach to

prevent parts getting lost and so that you can access them quickly after attaching the new

grinding disk.

3. Now take the worn grinding disk off the spindle.

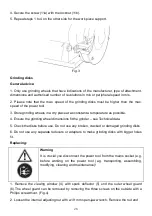

4. Place a new grinding disk on the spindle. Before doing so, ensure that the grinding disk is

undamaged and that it meets the technical requirements of this double grinder. Carry out a

sound test. Faultless grinding wheels will make a clear sound when struck gently with a

plastic hammer (or piece of wood) (Fig.5).

5. Put the tension flange (8) back on the spindle and secure with the adjusting nut.5.

6. Re-attach the wheel guard to the double grinder. Make sure when doing so that the open

side is facing the right way. It should point forwards. Tighten all the screws well.

7. Re-attach the viewing window with spark deflector on the double grinder.

Fig.5

Summary of Contents for 4673

Page 34: ......

Page 35: ...TBG 200 350 4673 ...