16

Trevi Spa User Guidea

Installation of a manual spa cover

Step 1: Preparation

▪

For installation, the following is required: drill with a star bit,

measuring tape and a pencil.

Note:

See content of the parts at the end.

▪

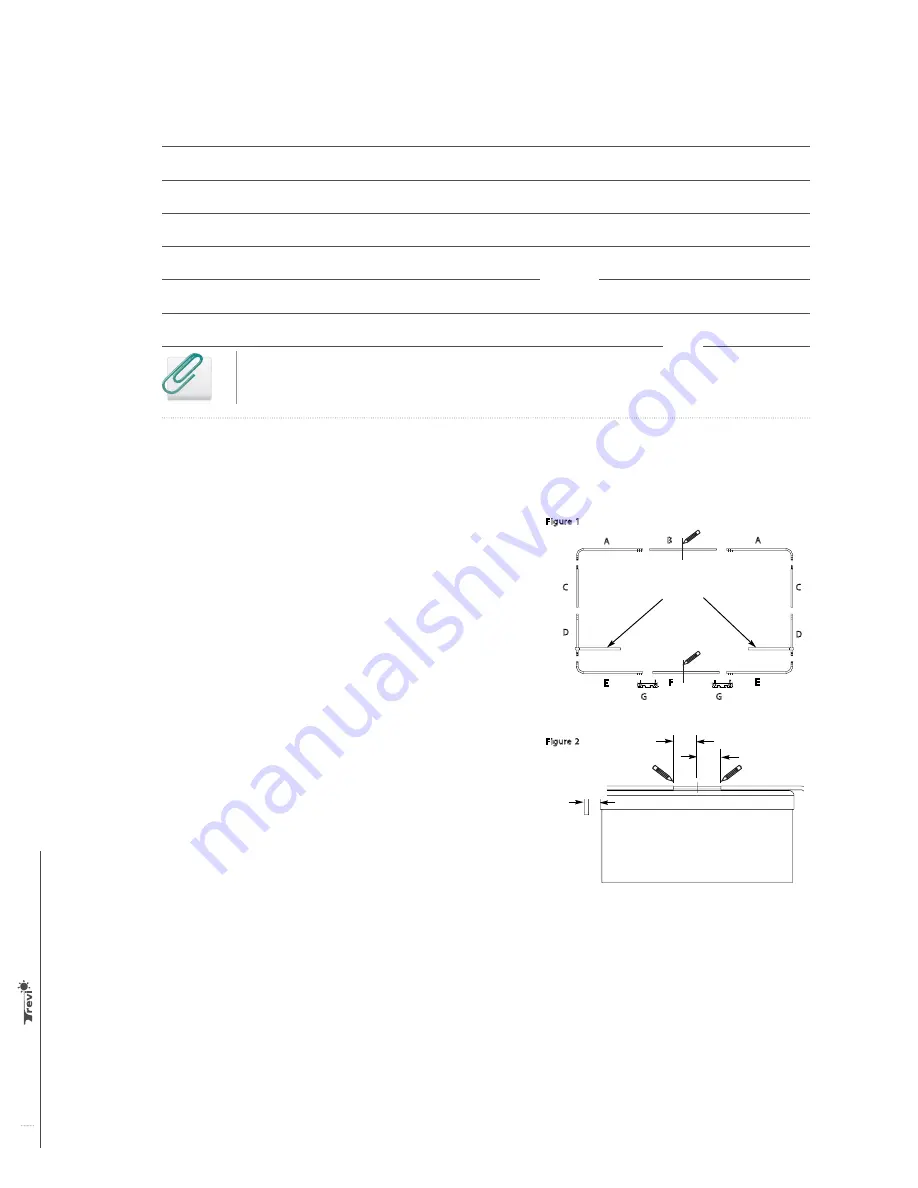

Place the frame parts to the ground next to your spa to form

a rectangle

(Figure 1)

. Mark the center of

(B)

and

(F)

with a

pencil. Insert a strap on each side in sections

(D)

.

Step 2: Assembly of the upper section

▪

Insert the ends of

(B)

in

(A)

. Place this section of the

framework thus formed on the central stitching of the cover.

Adjust the parts

(A)

so that they are approximately 6.5 cm

(2 1/2") from the sides of the cover. Center

(B)

in

(A)

using a

tape measure and the center mark. Make a pencil mark at the

junction of

(A)

and

(B)

(Figure 2)

.

▪

Place the upper section on the ground and align the pencil

marks made at the ends of

(B)

and

(A)

. Be sure that the short

sides of

(A)

are level to the other. Connect the different parts

of the upper section of the frame using 3/4'' long self-drilling

screws (3 at each end).

The screw heads should be inside

the frame.

▪

Insert the tapered end

(C)

in

(A)

. Connect

(A)

and

(C)

with the

5/16" x 1 5/8" long screws and nuts (2 per side). The nuts must

be facing towards the ground.

Figure 1

Figure 2

6.5 cm

2 1/2”

=

A

C

D

D

C

B

F

G

G

A

E

E

=

Figure 4

Jupe

du spa

G

50 cm

20”

4 vis

E

D

G

Courroies

Figure 1

Figure 2

6.5 cm

2 1/2”

=

A

C

D

D

C

B

F

G

G

A

E

E

=

Figure 4

Jupe

du spa

G

50 cm

20”

4 vis

E

D

G

Courroies

Figure 1

Figure 2

Figure 3

Strap

4 screws

skirt spa