08/10/2003

CT104 Manual

Tri-M Engineering

Tel:

800.665.5600, 604.945.9565

1407 Kebet Way, Unit 100

Fax:

604.945.9566

Port Coquitlam, BC V3C 6L3

E-mail:

info@tri-m.com

Canada

Web

site:

www.tri-m.com

8

3.2 Rubber Mounting Materials

Compound

- High Grade EPDM 80 extruded rubber

Rating

- ULHB94 Horizontal Burn Test, compound # 295-104-02-90

ETHYLENE PROPYLENE COPOLYMER

(EPM/EPDM) Elastomers prepared from ethylene and propylene

monomers , at times with a small amount of a third monomer (Etlylene Propylene Terpolymer). Excellent

resistance to phosphate ester type hydraulic fluids.

Specific gravity..........................................86

Tensile Strength.........................................3,000

Elongation, max.........................................6x

Hardness, Shore A.....................................30-90

Brittle Point (F)..........................................-90

The hardness testing of plastics is most commonly measured by the Shore (Durometer) test or

Rockwell hardness test

.

Both methods measure the resistance of the plastic toward indentation. Both scales provide an empirical hardness value

that doesn't correlate to other properties or fundamental characteristics. Shore Hardness, using either the Shore A or

Shore D scale, is the preferred method for rubbers/elastomers and is also commonly used for 'softer' plastics such as

polyolefins, fluoropolymers, and vinyls. The Shore A scale is used for 'softer' rubbers while the Shore D scale is used for

'harder' ones.

The Shore hardness is measured with an apparatus known as a Durometer and consequently is also known as

'Durometer hardness'. The hardness value is determined by the penetration of the Durometer indenter foot into the

sample. Because of the resilience of rubbers and plastics, the hardness reading my change over time - so the indentation

time is sometimes reported along with the hardness number. The ASTM test method designation is ASTM D2240 00.

Related methods include ISO 7619 and ISO 868; DIN 53505; and JIS K 6301, which was discontinued and superseded

by JIS K 6253.

The results obtained from this test are a useful measure of relative resistance to indentation of various grades of

polymers. However, the Shore Durometer hardness test does not serve well as a predictor of other properties such as

strength or resistance to scratches, abrasion, or wear, and should not be used alone for product design specifications.

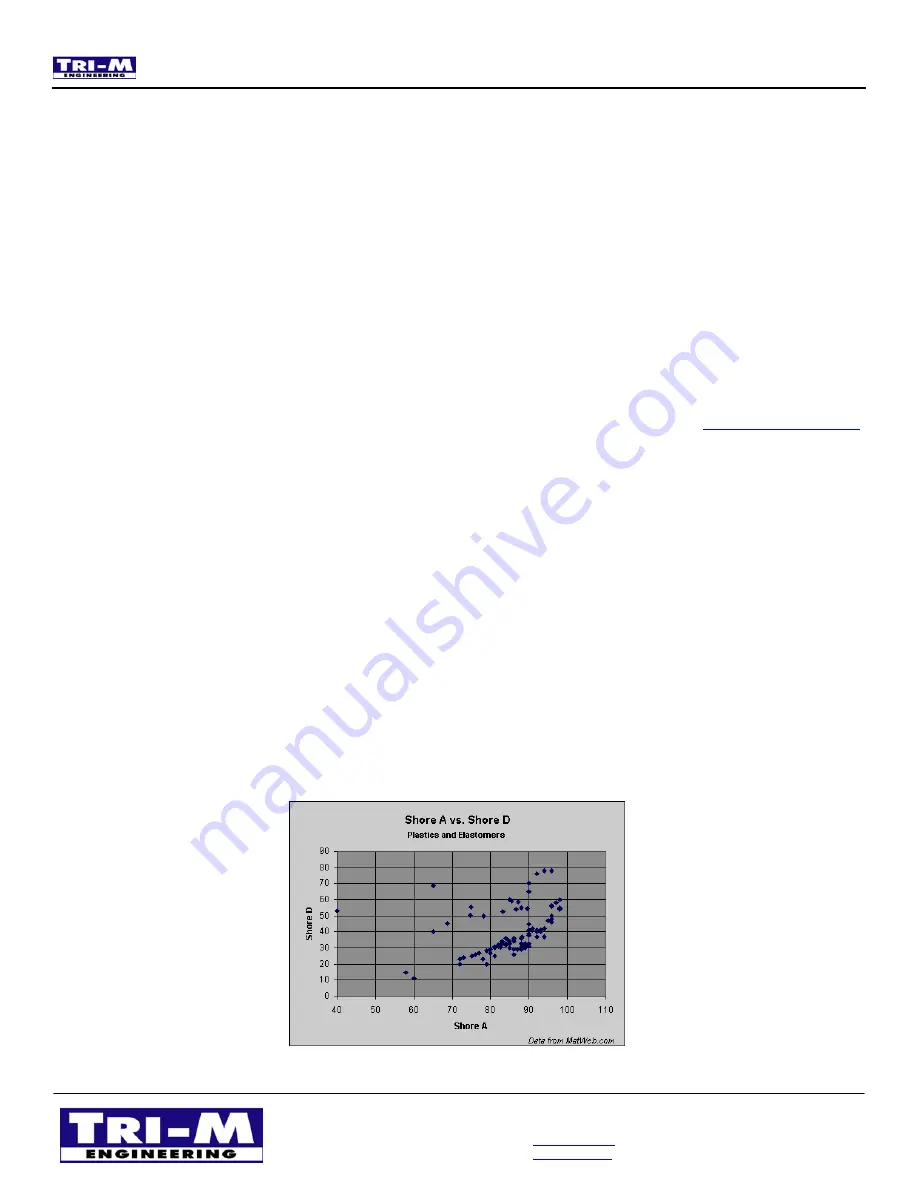

As seen in the charts below, the correlation between the two Shore Durometer hardness scales is weak; attempts at

conversion between the scales are therefore discouraged. The correlation is higher for materials with similar resiliency

properties, but is still too low for reliable conversions. Likewise, conversion between Shore Hardness and Rockwell

hardness is discouraged.