Page 40

Step 16.

Rotate the indenter plate, insert the cam arm into the arbor shaft and

set the plate onto the housing.

NOTE: The arbor shaft can be rotated slightly to facilitate cam arm insertion.

Step 17.

Proceed to Paragraph 6-9, Step 4.

The adjustment of indenters should be performed whenever existing indenters are

slightly worn and "G" dimension is out-of-tolerance, when Crimp Verification (Section

3) dictate adjustment is necessary, and when new indenters have been installed

(Paragraph 6-8).

Perform the following steps to adjust indenters:

Step 1.

Open the sleeve valve.

Step 2.

Disconnect the air supply from the sleeve valve.

Step 3.

Remove the crimp cylinder arbor cover plate and the funnel cover

plate.

Step 4.

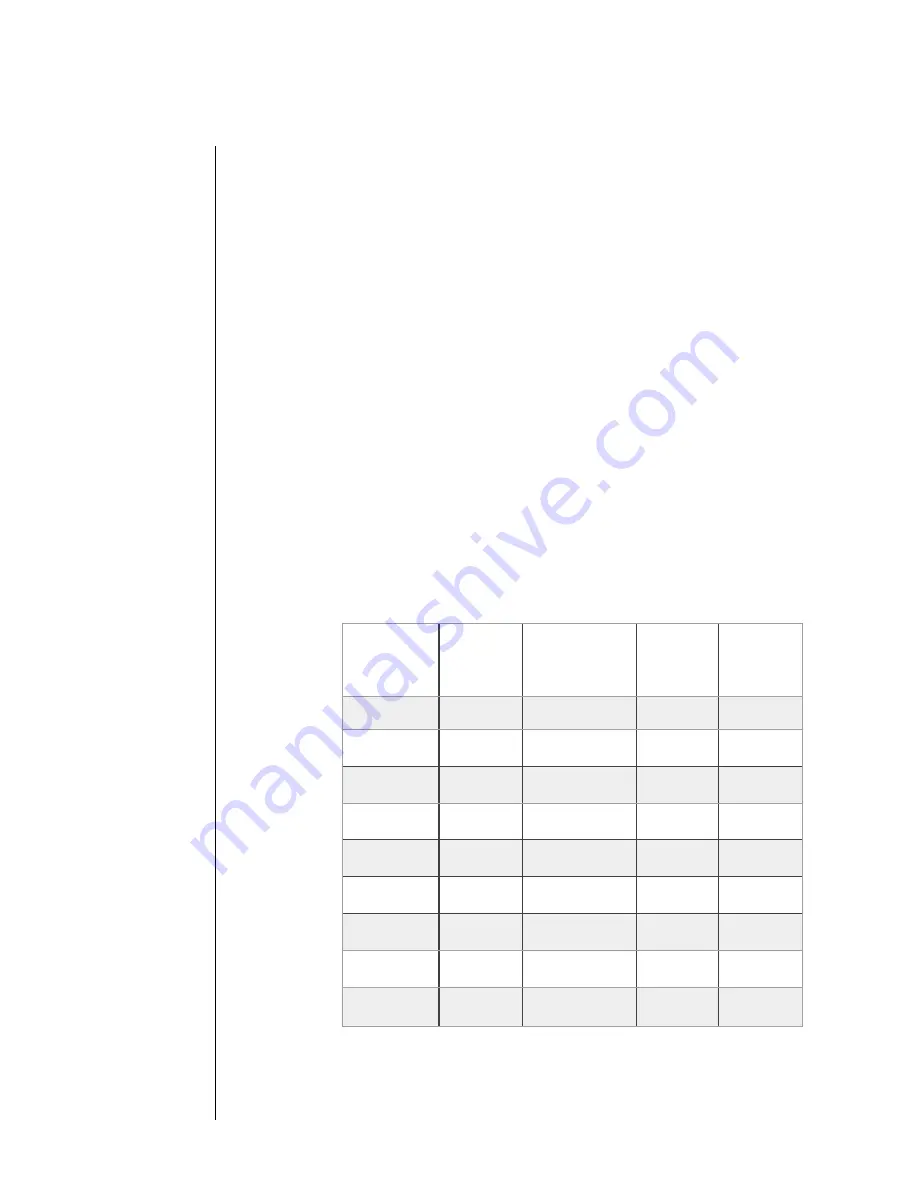

Refer to Table 6-1. If the TAC Crimper has an operator-adjustable "G"

dimension control, set the control to setting 6 (the largest wire gauge).

If the setting is not adjustable, perform the GO/NO-GO tests and adjust

I

NDENTER

ADJUSTMENT

Contact

Gauge

Setting

Wire

Gauge

Go

No-Go

22

1

26

.016

.021

22

2

24

.019

.024

22

3

22

.022

.027

20

4

24

.025

.030

20

5

22

.029

.034

20

6

20

.033

.038

16

1 or 4

20

.029

.034

16

2 or 5

18

.033

.038

16

3 or 6

16

.037

.042

Summary of Contents for TAC 17X

Page 5: ...Page 5 Figure 1 1 TAC 17X Front View ...

Page 7: ...Page 7 Figure 1 2 Wire Insertion Through Funnel ...

Page 10: ...Page 10 Primary air input at rear of TAC Figure 2 1 Pneumatic Hook Ups ...

Page 16: ...Page 16 Crimp Inspection Points Improper Crimps Figure 3 3 Crimped Samples ...

Page 25: ...Page 25 Figure 6 1 TAC 17X Pneumatic Control Panel ...

Page 26: ...Page 26 Figure 6 2 TAC 17X Components Right View ...

Page 38: ...Page 38 ...

Page 39: ...Page 39 Carefully Remove Hose Clamp ...

Page 42: ...Page 42 ...

Page 47: ...Page 47 Figure 7 3 TAC 17X Pneumatic Diagram ...