Theory of Operation

Section 5

TAC

·

7X

MANUAL

1. Introduction

2. Pneumatic

Supply

The TAC Crimper has been extensively redesigned. The redesign

results in additional logic functions being added to prevent possible

malfunctions, while at the same time reducing the overall number of

components.

All logic, control and operating functions of the TAC Crimper are

performed pneumatically, electrically or both.

The purpose of this Theory of Operation is to provide an overview of

how the TAC operates such that a general understanding of functions

can be achieved. In the event a TAC were to malfunction, familiarity

with its operational sequences will greatly expedite corrective action.

System design is such that many events are sequential and, unless the

TAC is positive a given event has properly occurred, subsequent events

will not occur. This design, in conjunction with high tolerance machined

components, reduces significantly the possibility of initiating crimps on

incorrect contacts, or proceeding to crimp additional contacts if proper

crimp tolerances are not being achieved.

If the crimped contact/conductor is not removed after the crimping cycle

is complete, the TAC will pause. The TAC will remain in the "pause"

position until the contact/conductor is removed.

*Please refer to Figure 6-1 & 6-2 while reading this Theory of Opera

tion.*

Air pressure is supplied to the TAC when the operator-controlled

Sleeve Valve (SV) is closed manually.

Electrical power is suppled to the TAC control system via an internally

mounted transformer. Transformer and feeder-bowl power is supplied

from standard 120V outlet (European model 220V). Transformer power

is switched on via switch S-5. Output from the transformer (12V DC) is

supplied to the PLC (control system) of the TAC

!

Summary of Contents for TAC-7AE

Page 6: ...Figure 1 1 TAC 7X Front View ...

Page 8: ... Figure 1 2 Wire Insertion Through Funnel ...

Page 12: ...Figure2 1 Pneumatic Hook Up ...

Page 14: ... Fiqure 2 4 Track Drop Tube Escapement ESCAPEMENT SYSTEM _ _ _ BR ASSEMBL I TRA ...

Page 18: ... ARBOR COVER PLA TE REMOVED Figure 3 1 Crimp Cylinder Arbor Open ...

Page 20: ... ARBOR COVER PLAT E REMOVED Figure 3 2 Crimp Cylinder Arbor Closed ...

Page 23: ... Crimp Inspection Points Improper Crimps ...

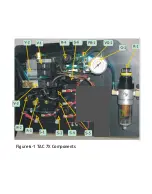

Page 33: ...Figure 6 1 TAC 7X Components ...

Page 34: ...Figure 6 2 Control Box Components Figure 6 2 TAC 7X Components Right View ...

Page 37: ...Figure 6 3 Contact Track Feed Air Adjustments ...

Page 42: ... Figure 6 4 Indenter Plate Removal ...

Page 43: ...HOSE CLAMP CAREFULL Y REMOVE Figure 6 5 Indenter Replacement ...

Page 47: ...Figure 6 6 Indenter Adjustment ...

Page 52: ...TAC 7X Pneumatic Diagram ...