TAC-7X

MANUAL

Step 2. Verify the alignment between the transfer tip and drop tube. If

alignment appears off, consult the factory or your local area

service representative for further instructions.

Step 3. If contact is fully seated in proper transfer tip, verify transfer tip

sensor S-6 is operational by performing the following:

A - Turn air off.

B - Remove contact from transfer tip.

C - Remove Power Cord from wall outlet.

D - Remove control unit cover.

E - Turn air on.

F - Locate S-6 and vacuum line.

G - Fully pinch vacuum line repeatedly and verify if S-6 is

switching on and off. An audible click should be heard from

the switch each time it is activated.

NOTE

Should the work environment be too noisy for an

effective audible check, an electrical meter may be

used instead. (Top tab is common, bottom tab is

normally open position).

Step 4.

If switch S-6 fails the above test, consult factory for adjustment

instructions. No adjustments should be attempted prior to

factory instructions.

7.

Trigger (Slide

Sensor)

Inserting a conductor into a contact and depressing it forces the transfer tip

slide down onto a slide sensor, initiating the crimp cycle.

If depressing the conductor into a contact does not initiate the crimp cycle,

perform the following checks:

-

With air turned off, inspect the trigger assembly to be sure

no foreign objects have lodged themselves in any of the

moving parts.

Summary of Contents for TAC-7AE

Page 6: ...Figure 1 1 TAC 7X Front View ...

Page 8: ... Figure 1 2 Wire Insertion Through Funnel ...

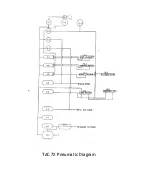

Page 12: ...Figure2 1 Pneumatic Hook Up ...

Page 14: ... Fiqure 2 4 Track Drop Tube Escapement ESCAPEMENT SYSTEM _ _ _ BR ASSEMBL I TRA ...

Page 18: ... ARBOR COVER PLA TE REMOVED Figure 3 1 Crimp Cylinder Arbor Open ...

Page 20: ... ARBOR COVER PLAT E REMOVED Figure 3 2 Crimp Cylinder Arbor Closed ...

Page 23: ... Crimp Inspection Points Improper Crimps ...

Page 33: ...Figure 6 1 TAC 7X Components ...

Page 34: ...Figure 6 2 Control Box Components Figure 6 2 TAC 7X Components Right View ...

Page 37: ...Figure 6 3 Contact Track Feed Air Adjustments ...

Page 42: ... Figure 6 4 Indenter Plate Removal ...

Page 43: ...HOSE CLAMP CAREFULL Y REMOVE Figure 6 5 Indenter Replacement ...

Page 47: ...Figure 6 6 Indenter Adjustment ...

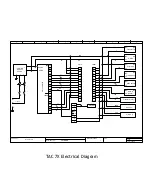

Page 52: ...TAC 7X Pneumatic Diagram ...