Model 300STS Tube Squaring Machine

92-1942 Orig. 210625

17

CAUTION

CAUTION: Do not let the tool bit touch the tube or pipe. This will damage the tool bit or

the Tube Squaring Machine when power is applied.

INSERT THE TUBE

OPERATION SEQUENCE

CAUTION

CAUTION: The Two Speed Gearbox Knob should be in the 1st gear position. If the Knob

does not snap into the desired position, turn the chuck by hand slightly until the Knob

snaps back into place. Put the speed control in the drill position. (Any other position

will limit the motor torque.)

1. Connect the Model 300STS to the power source.

2. Pull the Trigger to start rotation of the Cutting Head, Refer to the section on

Cutting Speeds and Feeds.

3. The Metabo Motor speed is controlled via the trigger. Use it to adjust the cutting

speed.

•

To obtain a minimum burr tube end, avoid heat build up. When the tube or the

tool bit gets hot, the tube material starts to flow or push away from the tool bit

edge in the form of a burr, instead of being cut cleanly with a minimum burr.

Keep the RPMs low to avoid generating excessive heat. An excessive cutting

speed will generate unwanted heat.

•

Keep the chip curl loose by avoiding very deep cuts. A dull tool bit will not do

the job right, so be sure that there is a sharp tool bit mounted in the Machine.

4. Rotate the Feed Collar clockwise (as viewed from the motor end) to bring the Cutting

Head and tube closer together. The machining operation begins when the tool bit

contacts the tube or pipe.

5. If the tube end is not square to the tube axis, the tool bit will contact only a small

segment of the tube during each revolution. To avoid tool bit damage, use a very

slow feed rate until the tool bit contacts the tube continually for at least one revolution.

6. Adjust the cutting RPM with the Speed Control Trigger until it is just above the

required cutting speed as the tool bit enters the cut. The tool will slow down slightly

as the cutting load increases. Apply additional power to hold the cutting speed.

1. Retract the feed to the start position.

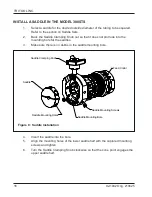

2. Insert the tube to be machined in the front of the Model 300STS. Position the tube

or pipe approximately 1/16” (1.6mm) from the tool bit.

3. Tighten the Saddle Clamping Knob to tighten the tube in the Saddle.