15

Model 208B BEVELMASTER

®

92-1482 Rev. 190410

Basic Tube Sizes

Up to .875" (22.2 mm) wall tubing with a maximum OD of 8.63" (219.2 mm) and a

minimum ID of 1.63" (41.4 mm) may be beveled with standard mandrel.

Wall Thickness Capacity

Wall thickness of all standard pipe schedules [.875" (22.2 mm) maximum] in the

range listed. Tubing with greater wall thickness may be handled provided the

ID is greater than 1.63" (41.4 mm) and the OD is less than 8.63" (219.2 mm).

Contact TRI TOOL Inc. for heavier wall procedures.

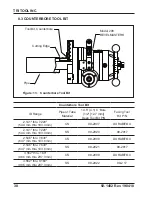

Counterboring Operations

The tool will counterbore pipe and tubing with an ID range of 2.141" (54.4 mm) to

8.160" (207.3 mm).

Material Cutting Capabilities

Mild steels, chrome steels (Rc 35 max.), stainless steel, copper-nickel and

aluminum without limitations other than size and wall thickness as specified.

Inconel and some other high-temperature alloys may require special procedures

as a function of wall thickness and type of end preparation. Contact TRI TOOL’s

Engineering Department for details.

Cutting Speeds

Maximum Head Speed - 110 RPM

Maximum Head H.P. - 60 RPM

Functional Head Range - 3-110 RPM

RPM @ 300 in/min (7620 mm/min)

• 8.63" (219.2 mm)/11 RPM

• 1.69" (42.9 mm)/56 RPM

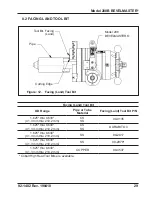

Feeds

Manual-Feed handle is in line at the back of the machine. Feed Rate is .083"

(2.1 mm) per revolution of the feed handle.

Maximum Feed Travel - 2.00" (50.8 mm)