TRI TOOL INC.

92-0699 Rev. 060412

14

5. MAINTENANCE

All components should be cleaned and coated with a light film of oil prior to use.

Use a clean, non-detergent oil, preferably SAE 10 (90 SSU) or lighter or oil as

specified for the air motor.

Air supply for the Model 204B BEVELMASTER™ with an Air Motor requires an

adequate filter/regulator/lubricator (FRL) to be used.

A maximum of 90 psi (621 kPa) line pressure is recommended.

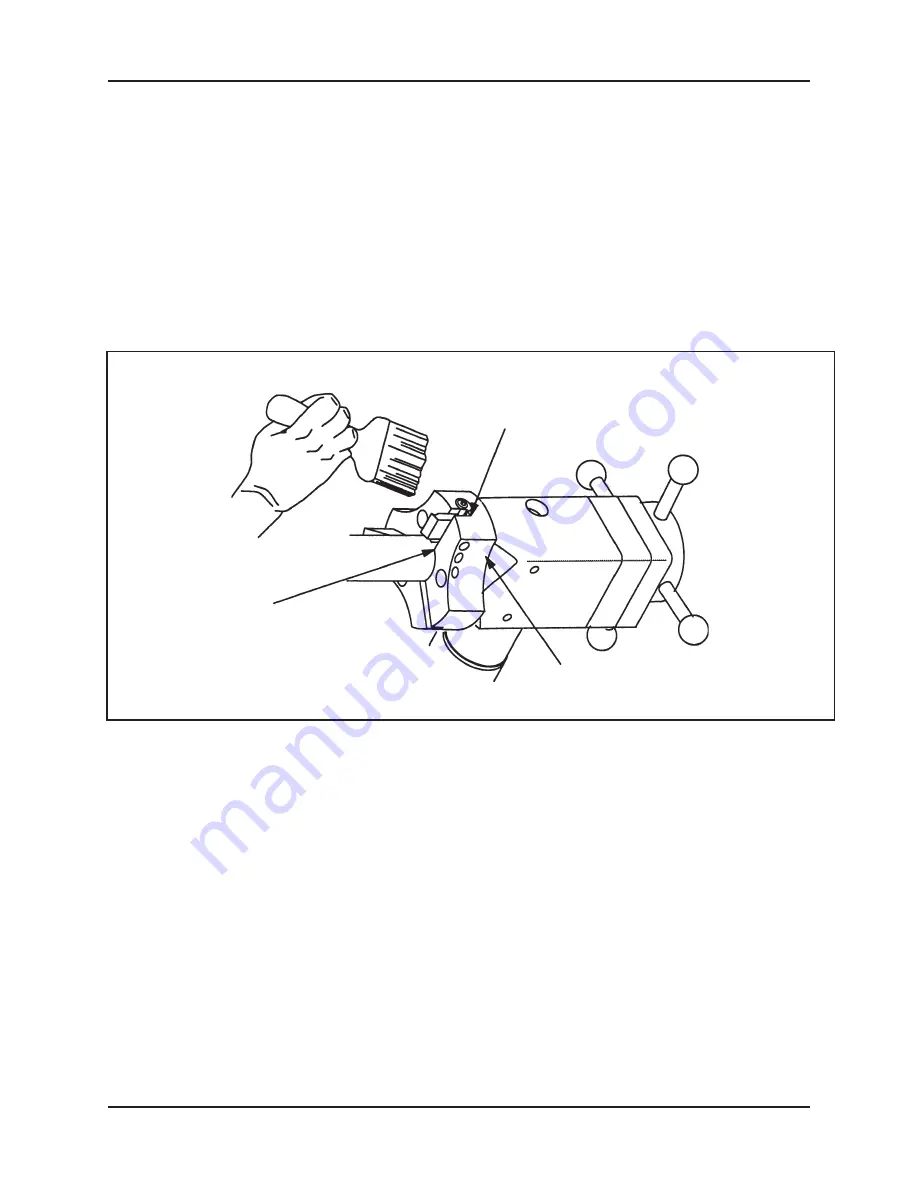

Clean Up

Clean Up

Clean Up

The motor warranty is void if damage occurs from contaminated air or lack of

lubrication.

When the Model 204B BEVELMASTER™ is operated in the vertical position,

cutting head up, it should be turned upside down and the chips and/or other debris

removed after each bevel has been completed.

Tool life may be severely shortened, unless chips and/or other debris that have

been deposited on the cutting head during the machining operations are removed.

Verify that there is adequate grease in the gear box. Gears and bearings are to be

lubricated using a lithium based grease.

Disassembly of a power unit voids warranty, except when performed by a TRI

TOOL INC. designated repair technician. A letter of designation is required.

Summary of Contents for BEVELMASTER 204B

Page 1: ...Operation Manual 92 0699 Rev 060412 Model 204B BEVELMASTER ...

Page 45: ......