41

Model 214B BEVELMASTER

®

92-1500 : Rev. 140425

NOTE:

Verify that there is adequate grease in the gear box. Bearing and gears are to be

lubricated using a high string utility grease (P/N 68-0024).

Disassembly of a power unit voids the warranty, except when performed by a

TRI TOOL INC. designated repair technician. (A letter of designation is re-

quired.)

AIR MOTOR LUBRICATION

No direct maintenance is normally required on the air motor.

However, the air supply must flow through a filter/regulator/lubricator (FRL) unit or

separate units before arriving at the air motor.

The FRL unit must be maintained as required (frequency dependent on the basic air

supply) to keep the water trap drained, filter cleaned and the lubricator oil reservoir

filled so that a drop of oil every 2 to 5 seconds is flowing.

When the Model 214B BEVELMASTER™ is to be left idle for 24 hours or more after

being run on ‘wet’ air, it is advisable to squirt oil directly into the air motor inlet and

run the motor for two (2) to three (3) seconds. This will prevent rusting and freezing

of the rotor.

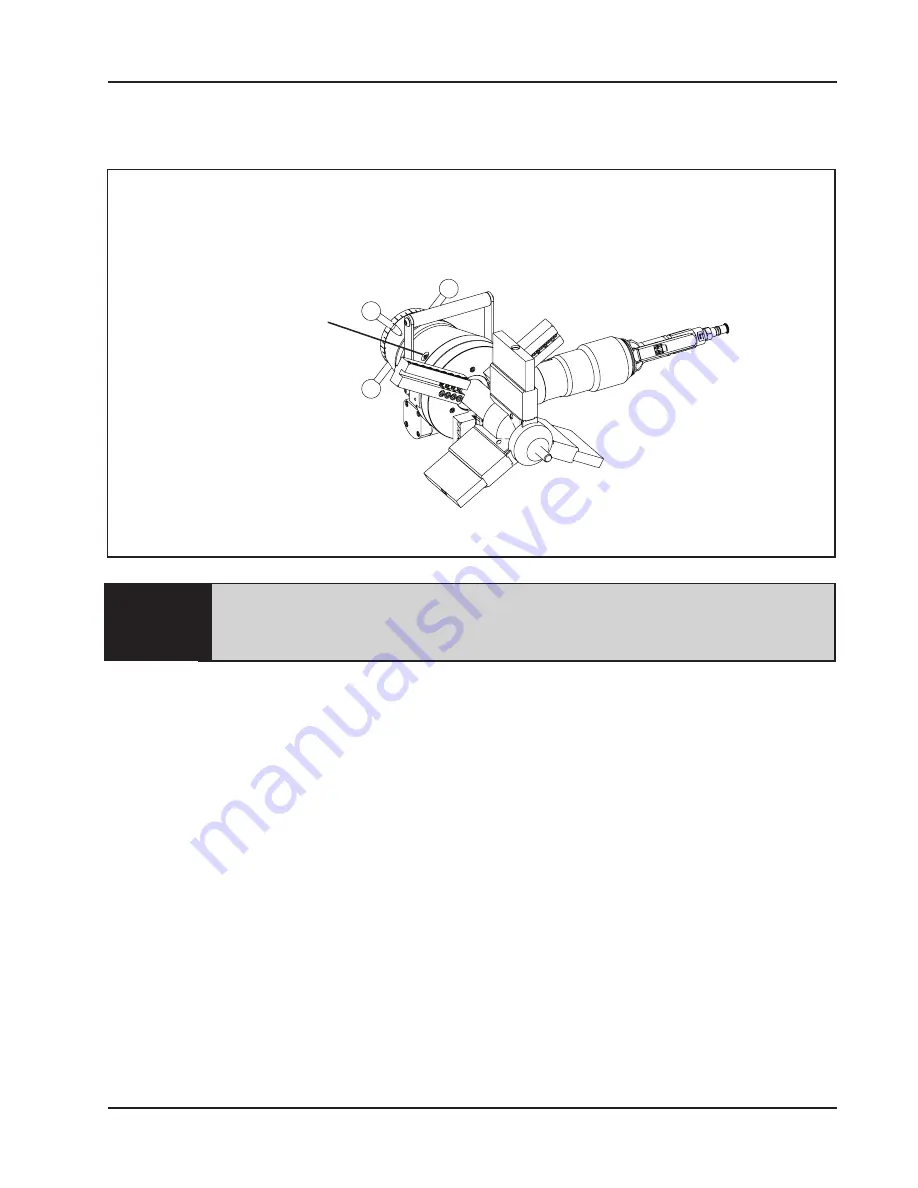

Grease Location

Check Lubrication