8

TRI TOOL INC.

92-1783 Orig. 161006

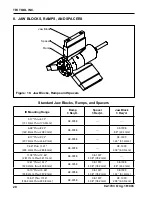

WeIgHT (APPROx.)

Machine without mandrel, tool modules, or motor: 119 lbs. (54.0kg)

3-Jaw Mandrel 51 lbs. (23.1 kg)

Tool Modules each 12 lbs. (5.4 kg)

Motor

Air: 17 lbs. (7.7 kg)

Hydraulic 31 lbs. (14.1 kg)

POWeR ReqUIReMeNTs

Air: 90 PSI (6.2 bar) @ 95 SCFM (2.7m³/min)

Hydraulic: 20gpm (1.3 l/s) @ 1250 psi (86.2 bar)

feeD RATe

.083” (2.1 mm) per rev of the Feed Handle

feeD TRAVeL

3.00” (76.2 mm)

MAx. ROTATINg DIA

18.44" (468.5 mm)

CUTTINg CAPACITIes

Basic Pipe Sizes

Schedule 5 through 160 for 6" pipe, schedules 10 through 160 for 16” pipe,

and all schedules of 8" through 14” pipe.

Basic Tube Sizes

Up to 1.50” (38.1 mm) wall tubing with a maximum O.D. of 16.00” (406.4 mm)

and a minimum I.D. of 5.18” (131.5 mm) may be beveled with the standard

mandrel.

Wall Thickness Capacity

Wall thickness of all standard pipe schedules 1.500” (38.1 mm) maximum in

the range listed. Tubing or pipe with a greater wall thickness may be handled

provided the I.D. is greater than 5.18” (131.5 mm) and the O.D. is less than

16.00” (406.4 mm). Contact Tri Tool for heavier wall procedures.

COUNTeRBORINg OPeRATIONs

The tool will counterbore pipe and tubing with an I.D. range of 6”

(152.4 mm) to 16.00” (406.4 mm).

4. sPeCIfICATIONs