11

Model 216B BEVELMASTER

92-1783 Orig. 161006

5. Remove the Lathe Stand from the Machine.

6. Select the tool bit(s) required to machine the pipe to the configuration desired.

Use of dull or improperly designed tool bits or tool bits not manufactured by

TRI TOOL INC. may result in poor performance and may constitute abuse of this

machine and therefore voids the TRI TOOL INC. factory warranty.

7. When performing any multiple machining operation such as facing, beveling, and/

or counterboring, install the counterbore tool bit to ‘lead’ the bevel tool bit.

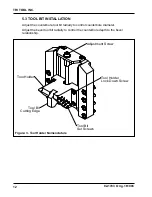

8. Position the Tool Holder by loosening the tool holder lock down screws. Then

rotate the adjustment screw to move the tool holder up or down. Tighten the told

holder lock down screws when the tool holder is in position to prep the pipe (Fig #3).

9. Insert the tool bit(s) into the slot(s) in the tool holder(s).

10. The cutting edge of the tool bit(s) must be located on the radial centerline.

11. Ensure that none of the tool bits are installed backwards.

12. Tighten the tool bit set screws to secure the tool bit(s) to the tool holder(s).

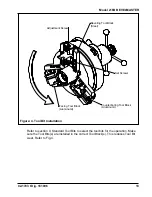

13. Attach the Air Motor with proper air supply to the Model 216B.

14. Check that the filter/regulator/lubricator (FRL) is installed and set properly.

CAUTION

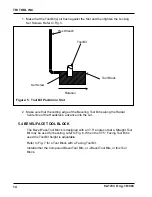

CAUTION: Do not operate the Machine without the mandrel stop

in place.

CAUTION

CAUTION: Do not operate the Machine with the Lathe stand installed

on the Machine. The Lathe stand mounted on the machine can

create pinch points if not removed.