16

TRI TOOL INC.

92-1783 Orig. 161006

5.5 COUNTeRBORe TOOL BLOCk

The Counterbore Tool Block is designed with a 5° back angle to provide Tool Bit

clearance, refer to Fig. 8.

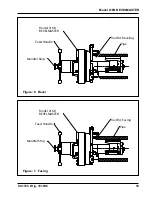

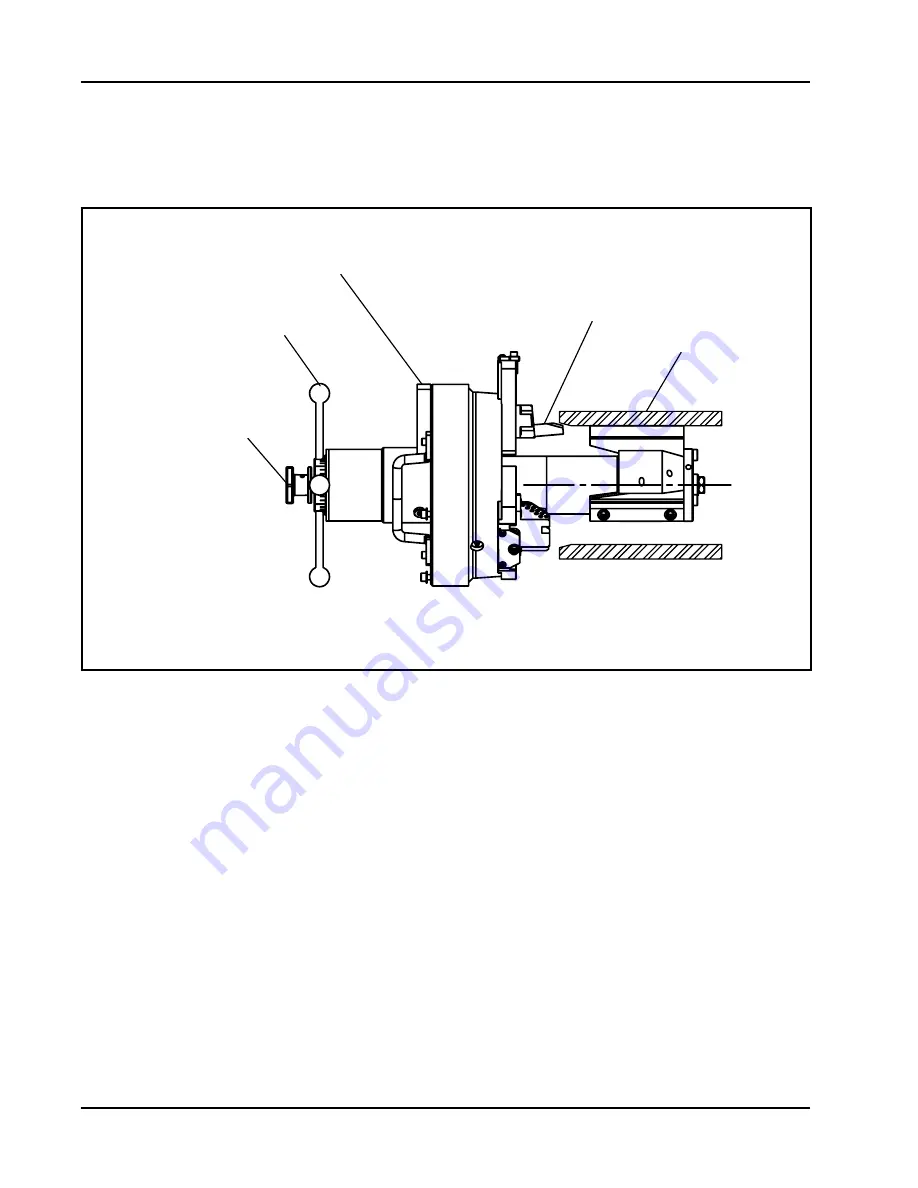

5.6 INsTALL JAW BLOCks

Refer to section 8, Jaw Blocks, Ramps and Spacers, to select the Jaw Blocks for

the operation.

1. Set the Jaw Blocks into the Ramp Blocks and tighten them. If the Jaw Blocks

do not mount smoothly, check for burrs and remove them with a file.

2. Install the machine into the pipe. To avoid cutting the Jaw Blocks with the tool

bits during the machining operation, the Jaw Blocks on the Mandrel Head must

be installed beyond the final end preparation location. Refer to Fig. 9.

3. Tighten the Draw Rod clockwise to force the Jaw Blocks out against the inside

diameter of the pipe.

4. Verify a minimum clearance of 1/8” (3 mm) between the Tool Bit(s) and the

pipe face as held by the Mandrel.

figure: 8. Counterbore

Pipe

Tool Bit, Counterbore

Model 216B

BEVELMASTER

Feed Handle

Mandrel Stop

Tool Bit Counterbore