17

Model 236B BEVELMASTER™

92-1306 : Rev. 090225

NOTE:

CAUTION:

Attach the proper supply line to the Drive Motor.

When using an Air Motor, use an adequate in line Filter, Regulator, Lubricator,

(FRL).

Turn the power on.

Adjust the cutting speed by opening the Flow Control Valve at the Power Supply

connection.

Rotate the Feed Knob clockwise to bring the Headstock and pipe closer together.

The actual machining operation will begin when the first Tool Bit makes con-

tact with the pipe.

If the pipe end is not square with the pipe axis, the Tool Bit will contact only a

small segment of the pipe during each revolution.

To avoid Tool Bit damage, the feed rate should be very slow until the Tool Bit has

contacted the pipe continually for at least one full revolution.

Continue rotating the Feed Knob clockwise until the end of the pipe is completely

machined.

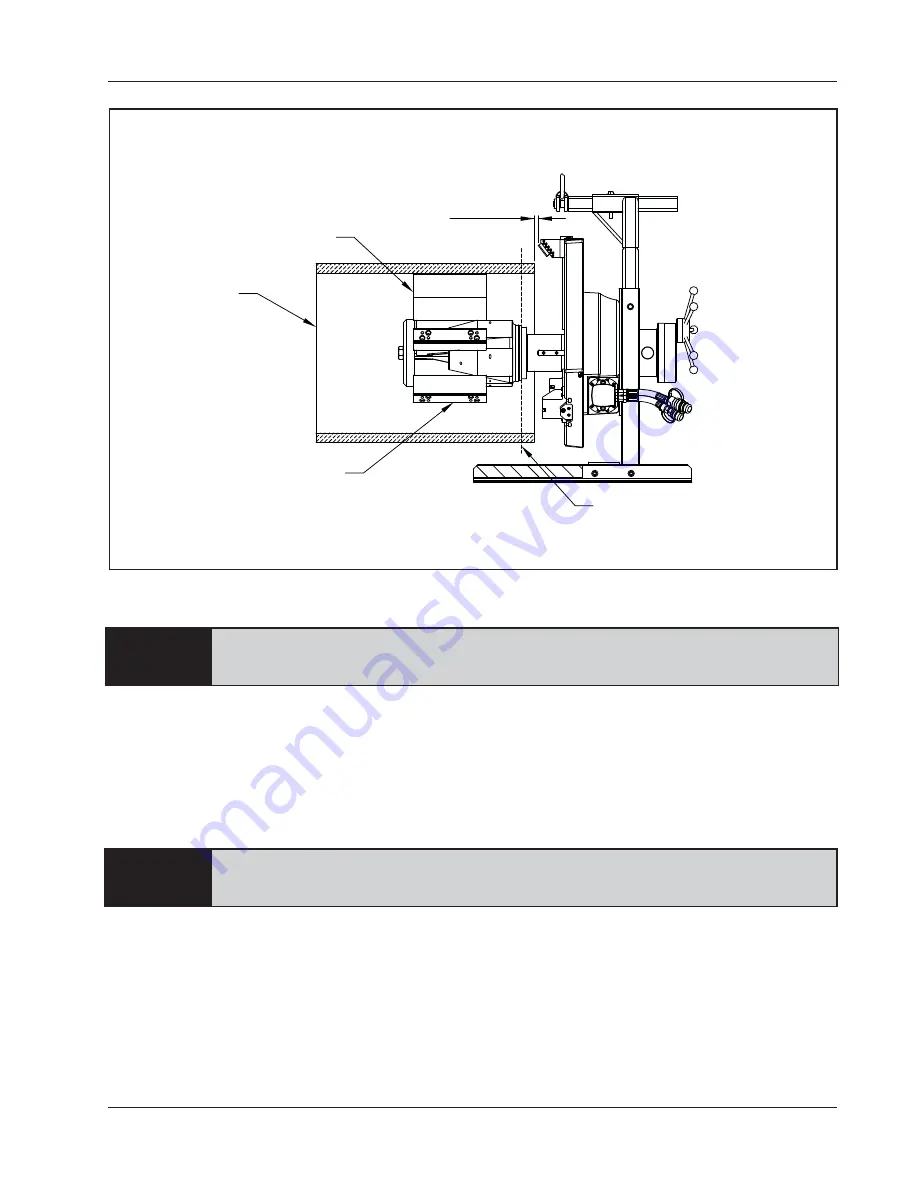

Jaw Block

Pipe

Mandrel Head

Clearance

Final Prep Location

Final Prep Location