2

Instinct FSB (Floor Standing Boiler)

HMI (Human Machine Interface) Removal

1. Preliminary Instructions

1. Verify that the

replacement kit is correct for the

model of boiler.

2. Carefully open and unpack the PARTS BOX from its

shipping carton.

3. Carefully remove and check for any damage.

NOTICE

Installing damaged

equipment will cause malfunction of the

boiler. Contact Triangle Tube right away if the display mod-

ule is damaged in any way.

4. Close the manual gas shut off valve to the unit.

5. Turn the power to the boiler off.

2. Save Settings

NOTICE

Prior to replacing the control module and/or display module, it

is important to access and document the boiler’s settings. This

will ensure any settings revised from factory defaults are trans-

ferred to the new module(s). Use Table 1 to record the existing

settings. Do not revise any settings when recording settings.

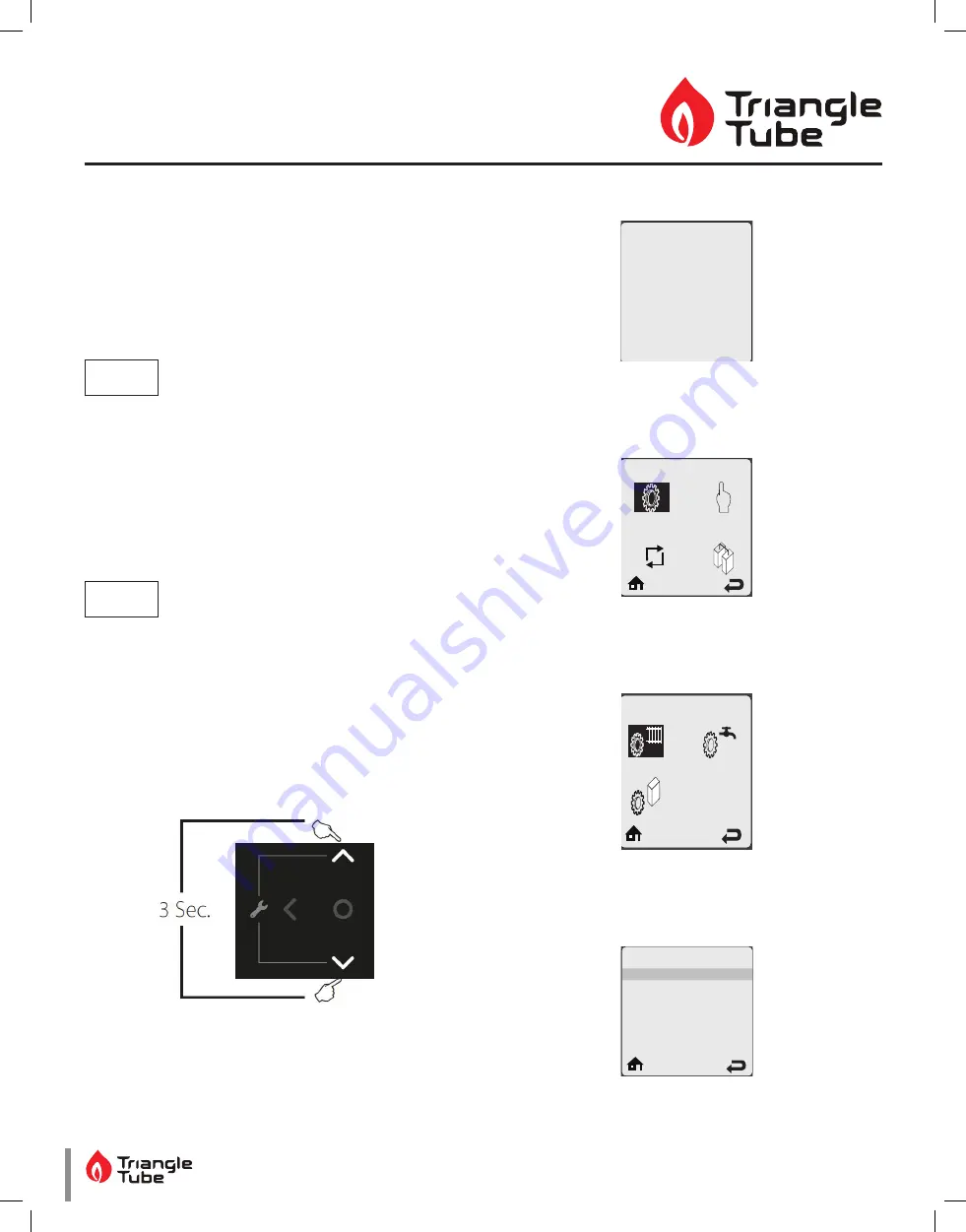

1. To access the Installer screen, touching simultane-

ously the up and down soft keys for 3 seconds as

shown in Fig. 1.

Fig. 1: Installer Button

2. Enter the installer access code “054” by using the

LEFT

and

RIGHT

buttons to select a digit and the

UP

and

DOWN

buttons to change the digit. Press

the OK button to enter the access code.

ENTER INSTALLER

ACCESS CODE

[0]XX

Fig. 2: Installer Access Code

3. Press the OK button while the CH & DHW Settings

icon is highlighted.

CH & DHW Settings

Fig. 3: CH & DHW Settings

4. Press the OK button while the CH Settings icon is

highlighted.

CH Settings

Fig. 4: CH Settings

5. Press the

UP

and

DOWN

buttons to scroll through

the various settings.

Heating Settings

Heating Operation

Demand

Absolute Max CH Setpoint

CH1 Maximum Setpoint

CH1 Minimum Setpoint

Reset Curve Coldest Day

Enabled

Switch & Setpoint

188ºF

180ºF

120ºF

0ºF

Fig. 5: Heating Settings