The control panel will display a H followed

by the current boiler temperature when

placed into high fire test mode.

2. If the combustion levels during high fire are

outside the recommended combustion settings

adjust the THROTTLE SCREW (see Fig. 5) as

follows:

Counter-clockwise adjustment of the THROT-

TLE SCREW at High Fire:

O2 decreases and C02 increases

Clockwise adjustment of the THROTTLE

SCREW at High Fire:

O2 increases and CO2 decreases

3. Once the combustion level is set at high fire,

manually place the boiler into low fire mode by

pressing the MODE button with “-” button

simultaneously on the control display while in

the standby (STBY) mode.

The control panel will display a L followed

by the current boiler temperature when

placed into low fire test mode.

4. If the CO

2

combustion level at low fire is not

/- 0.2 of the combustion level measured

at high fire, remove the offset cover screw and

adjust the plastic

OFFSET SCREW

using a T-

40 Torx wrench (see Fig. 5) as follows:

Counter-clockwise adjustment of OFFSET

SCREW at Low Fire:

O2 increases and CO2 decreases

Clockwise adjustment of OFFSET SCREW at

Low Fire:

O2 decreases and CO2 increases

5. Press the “+” and “-” buttons simultaneously to

shutdown the burner.

TriMax Instructions

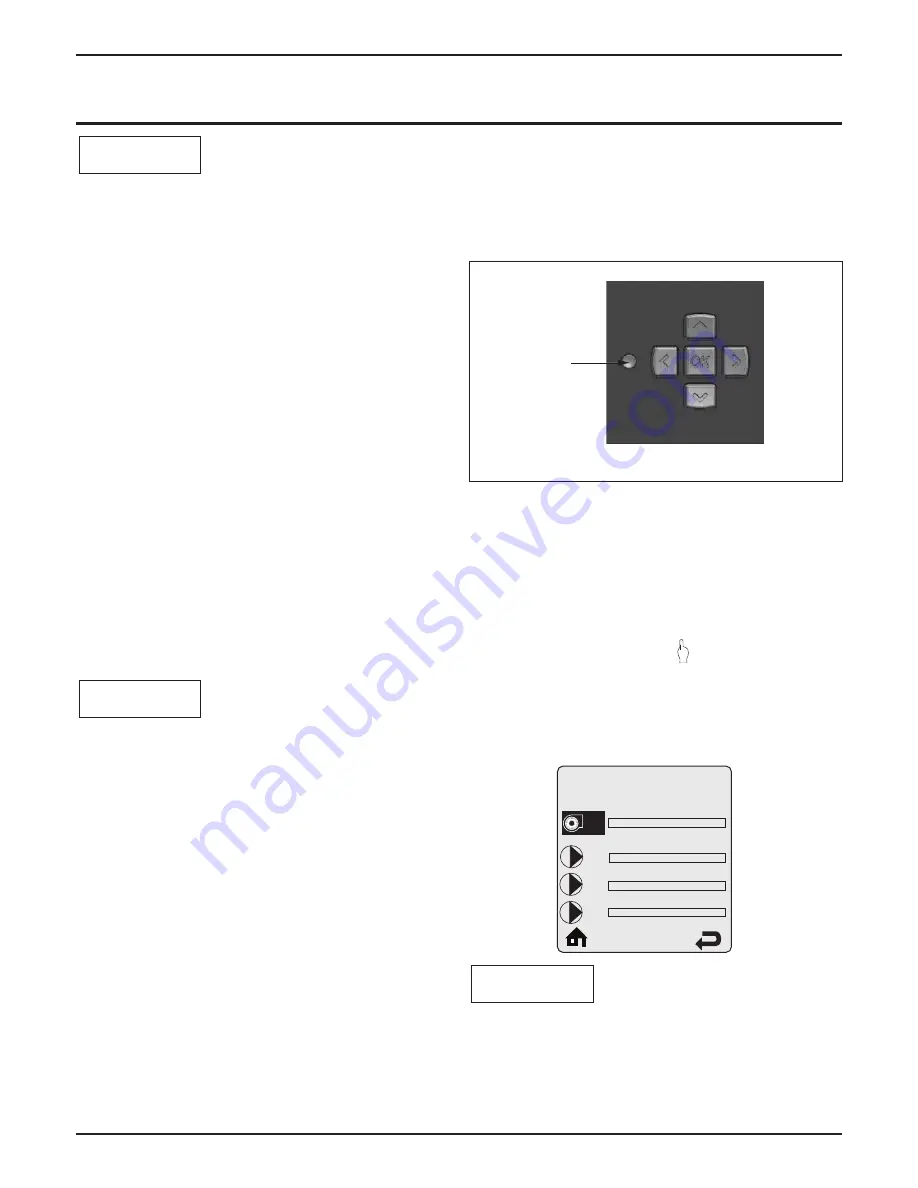

1. Press the round INSTALLER button. See Fig. 6.

2. Enter the installer access code “054” by using

the

LEFT

and

RIGHT

buttons to select a digit

and the

UP

and

DOWN

buttons to change the

digit. Press the

OK

button to enter the access

code.

3. Press the

RIGHT

button to highlight the

Manual Operation icon

then press the

OK

button.

4. Press the

OK

button while the FAN icon is

highlighted to manually fire the burner and

power the CH circulator.

An adequate CH load must be present to dissi-

pate the heat generated during the combustion

test. If an adequate CH load is not available, an

indirect water heater can be used to dissipate the

heat by creating a DHW call which will enable

the DHW circulator.

NOTICE

NOTICE

NOTICE

Prestige SOLO 399

Burner Mounting Plate Kit

5

Installer

Button

Fig. 6: TriMax Navigation Buttons

Manual Operation

Released

Off

Off

Off

CH

CH1

FAN

DHW

SYS

CH2