Prestige SOLO 399

Burner Mounting Plate Kit

7

The combustion chamber insulation con-

tains ceramic fibers, which are classified as

a possible human carcinogen. When

exposed to extremely high temperatures,

the ceramic fibers, which contain crys-

talline silica, can be converted into cristo-

balite.

Avoid Breathing and Contact with Skin and

Eyes

When removing or repairing the combustion

chamber insulation follow these precaution mea-

sures:

1. Use a NIOSH approved respirator which

meets OSHA requirements for cristobalite

dust, similar to N95. Contact NIOSH at:

1-800-356-4676 or on the web at

www.cdc.gov/niosh for latest recommendations.

2. Wear long sleeved, loose fitting clothing,

gloves and eyes protection.

3. Assure adequate ventilation.

4. Wash with soap and water after contact.

5. Wash potentially contaminated clothes sepa-

rately from other laundry and rinse washing

machine thoroughly.

6. Discard used insulation in an air tight plastic

bag.

Niosh Stated First Aid:

Eye/Skin: Immediately irrigate

Breathing: Clean fresh air

WARNING

Handling of Previously Fired Combustion Chamber Insulation

Revised 3/4/15

2015-02 Solo 399 Burner Mounting Plate Kit

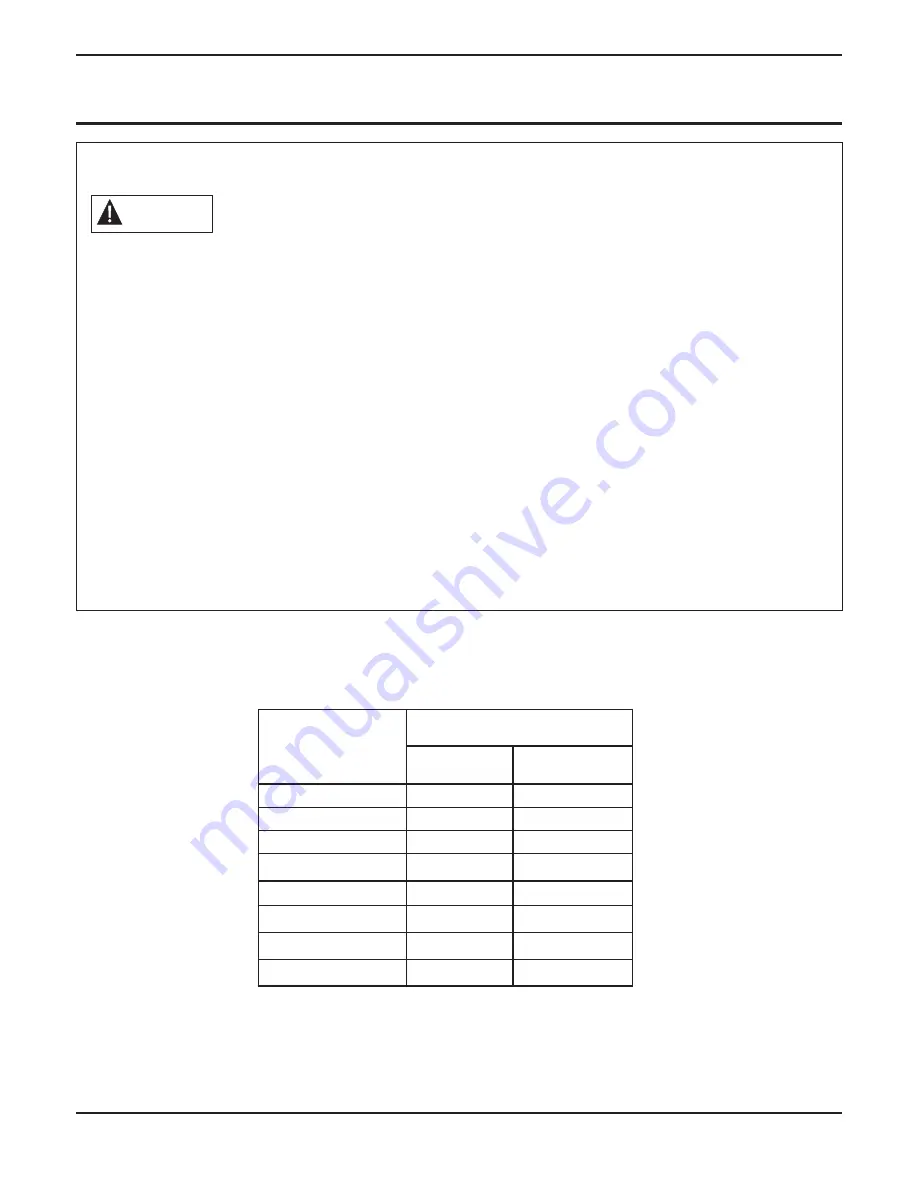

Table 2: Torque Specifications

Assembly Screws

Torque Specifications

Min.

Inch- Pounds

Max.

Inch- Pounds

Sight Glass

11

13

Burner Head

27

31

Igniter

27

31

Gas Valve Couplings

27

31

Blower - Outlet

27

31

Venturi to Gas Valve

31

35

Venturi to Blower

31

35

Burner Plate

44

59